Showing all 2 results

Table Contents

- 1. Introduction of flexible conveyor

- 2. Specification of flex conveyor systems

- 3. Structure & features of expandable conveyor

- 4. Working principle of flexible expandable conveyor

- 5. How to customize the flex portable conveyor

- 6. Case show & solution design

- 7. Installation and debugging

- 8. Extendable conveyor maintenance

- 9. Use precautions of flexible conveyor system

- 10. FAQ

Introduction of flexible conveyor

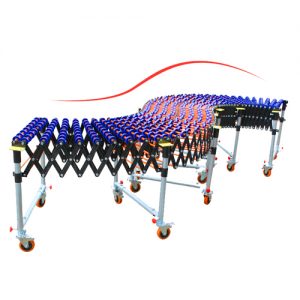

Different from ordinary conveyors, the flex conveyor adds a telescopic mechanism. So it allows the conveyor to expand freely in the length and direction. It uses expandable components as a frame. Thus, the extendable conveyor can not only change direction freely, but also can change any angle. In addition, the height of the legs is adjustable. Because of the casters, it is portable and movable. At the same time, straight sections and arc sections can be formed as requirements. Layout is flexible. This portable conveyor mainly includes two types. One is expandable roller conveyor, and another is skate wheel conveyor.

The expandable conveyor application. The telescopic flex conveyor is mainly used for sorting and conveying in the logistics industry. For example, you can use it for the transportation of packing boxes and turnover boxes. Of course, it is mainly suitable for conveying goods with flat bottom surface. Moreover, it can also act as truck loading unloading conveyor. It can reduce manual handling and reduce labor costs. At the same time, it can connect expandable conveyor with other conveyor machines. Therefore, it can realize the transportation of goods in different operation stages and different occasions. In addition, it can also be used for the transfer of factory assembly line operations.

Specification of flex conveyor systems

The Specification of flexible roller conveyor

| Product Name | Single-roller Flexible Conveyor | Double-roller Flex Conveyor |

| Drive Type | “With motor” or “without motor” | “With motor” or “without motor” |

| Conveying Speed for Powered Conveyor | Max 20m/min | Max 20m/min |

| Frame Material | Painted carbon steel, stainless steel, Aluminum or customized | Painted carbon steel, stainless steel, Aluminum or customized |

| Roller Material | Stainless steel, Galvanized steel, PVC, rubber coated roller | Stainless steel, Galvanized steel, PVC, rubber coated roller |

| Roller Diameter | Φ38, φ50, or customized | Φ38, φ50, or customized |

| Roller Length (mm) | 500, 600, 800 or customized | 500, 600, 800 or customized |

| When open, between each two rollers, Max gap from center to center | 125mm | 125mm |

| Roller Quantity for Each Unit | 10pcs or customized | 10pcs or customized |

| Load-bearing Capacity | 150KG | 150KG |

| Closed Length ~ Open Length for Each Unit | For instance φ38 roller, 560mm~1350mm, or customized | For example φ38 roller, 560mm~1350mm, or customized |

| Conveyor Height (adjustable) | 450~650mm, 570~850mm, 750~1100mm, or customized | 450~650mm, 570~850mm, 750~1100mm, or customized |

The specification of skate roller conveyor

| Product Name | flexible skate wheel conveyor |

| Drive Type | without motor |

| Conveying Speed for Powered Conveyor | Max 20m/min |

| Frame Material | Painted carbon steel, stainless steel, Aluminum or customized |

| Skate Wheel Material | ABS + bearing, or alloy + bearing |

| Telescopic Board | Alloy telescopic board |

| Skate Wheel Diameter | Φ5mm, or customized |

| Skate Wheel Quantity for Each Connection Bar | 8pcs or customized (each unit has 9pcs connection bars) |

| Load-bearing Capacity | 80 KG |

| Closed Length ~ Open Length for Each Unit | Close length is 31cm, and open length is 1.7m |

| Conveyor Height (adjustable) | 450~650mm, 570~850mm, 750~1100mm, or customized |

Structure & features of expandable conveyor

The structure of the retractable conveyor is simple. Therefore, it is not only easy to install, but also easy to use and maintain. This portable conveyor mainly composes of the following parts, such as supporting legs, telescopic plates, and rolling parts (rollers or skate wheels). If it is a powered flexible conveyor, it also includes a motor and a control box.

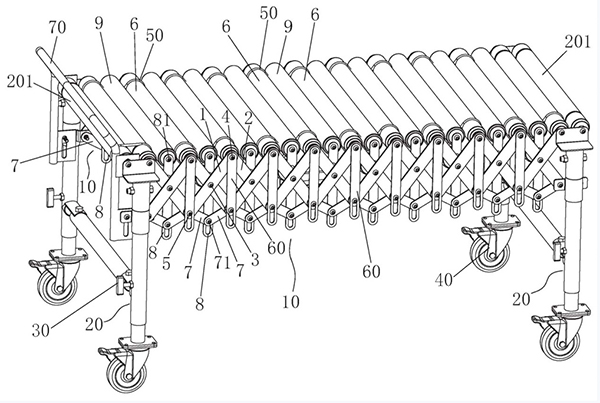

The structure of flexible gravity roller conveyor

(Conveyor Structure Details: 1-support rod, 2-support rod, 3-middle bolt, 4-upper bolt, 5-lower bolt, 6-main roller, 7-support rod, 8-support rod, 9-auxiliary roller, 10-foldable frame, 20-support leg, 30-bolt for height-adjustment, 40-universal wheel with brake, 50-transmission belt, 60-telescopic rod, 70-stop frame, 71-bolt, 81-bolt, 201-roller)

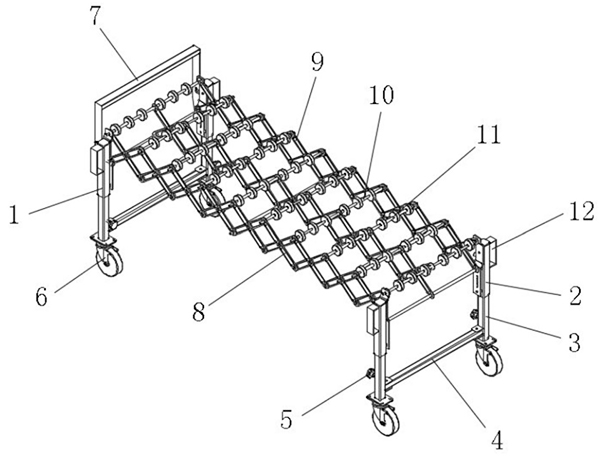

The structure of expandable wheel conveyor

(The parts of portable wheel conveyors are as follows: 1. The first support frame; 2. The second support frame; 3. Support legs; 4. Reinforcement rods; 5. Torx bolts; 6. Universal wheels; 7. Handle; 8. 9. The first telescopic plate; 9. The second telescopic plate; 10. The support shaft; 11. The skate wheel; 12. The fixed handle.)

The features & advantages of flexible gravity conveyor

1. Firstly, this portable conveyor only occupies a small area. Besides, it can expand freely. The ratio of the “expanded length” to “shortened length” is about 2.5~3 times.

2. Secondly, the direction of flex conveyor is easy to change. Moreover, it can change the conveying direction flexibly. 180° or 360° is achievable.

3. Thirdly, there are various conveying carriers. It not only can be rollers, but also skate wheels.

4. Low cost, simple structure, convenient maintenance, reliable operation and strong conveying capacity.

5. Use 2.5mm thick telescopic plate. Further, there is surface black electrophoresis treatment. So it is reliable and durable.

6. One end of the expandable portable conveyor is equipped with a handle. Thus, it’s convenient for pushing, pulling and moving. Moreover, it can alao act as a blocking device to prevent the goods from falling.

7. In addition, it can connect multiple sets of expandable conveyors together. So this can form a very long conveyor line.

8. The caster device is easy to move. Besides, the lifting device can flexibly adjust the height. And the flex conveyor can achieve straight, curved, and slope operations.

9. The telescopic portable conveyor can be connected with other conveying equipments. Further, you can move it to other unloading platforms. In short, it has high flexibility.

10. Save loading and unloading time

Take unloading as an example. According to the traditional unloading process, workers are required to unload the goods from the truck. And then put them on the conveyor lines. Or multiple workers hand in hand to the conveyors.

But after using the portable flexible conveyor, workers can easily put the goods on the conveyor. So it greatly save the time spent on loading and unloading.

11. Finally, we can customize the flex conveyor according to specific requirements. For example, you can tell us your sizes and carrying capacity. Then we can produce it.

For example, a truck contains 4000 pieces of goods. It needs 4 people to unload the cargo for 6~8 hours. Each worker costs $32 per day. Then 4 people will cost $128 yuan. For one month, it will be $3840.

If use the expandable flexible conveyor, it will only need 2 people. The unloading time can be shortened to 2~3 hours. The two worker’s fee is only $50. If a month, it is only $1500.

Then you can buy a flex conveyor for one month’s unloading fee. Moreover, the portable conveyor can be used for many years.

Working principle of flexible expandable conveyor

Firstly, the conveying distance of traditional conveyors is generally fixed. That is to say, this kind of conveyor can only transport materials at a fixed distance or a small range of variable distance. However, when the distance of conveying materials continues to expand, it can continue conveying. At this time, it must use flex portable conveyor.

How does flexible conveyor expand the length? It adjusts the length through the telescopic plate. At the same time, it achieve turning through the different extended distances of the inner and outer telescopic plates. Besides, the flex portable conveyor can work normally during the process of telescopic and turning.

The specific process is as follows: Firstly, install multiple sets of telescopic paltes on the rack crosswise. Secondly, install the transition wheel at the intersection of the telescopic plates. Then install a transmission belt on it. In addition, install the rollers and movable shafts on the upper and lower vertices of each group of telescopic plates. At the same time, install a power transmission device between each two rollers. Finally, the motor trasmit the power to the double groove transition wheel through the belt wheel. Then it is transmitted to the roller by the transition wheel through the transmission belt. Finally, the drum runs. At the same time, through the interaction force between the roller and the conveyed goods, it guide and push the goods to move. So it completes the entire conveying action.

How to customize the flex portable conveyor

During the process of daily sorting and loading and unloading of goods, we often encounter application scenes of objects with smaller bottom area or large arc curves. At this time, it is most suitable to use the unpowered skate wheel conveyor. Compared with steel skate wheels, the starting torque of plastic skate wheels is smaller. Therefore, if the weight of the object is light and the bottom material is not wear-resistant, it’s better to use the plastic flexible skate wheel conveyor. On the contrary, if the object is heavier, it’s better to use steel expandable skate wheel conveyor.

The wheel conveyor is usually unpowered. But for flexible roller conveyor, it can choose the motorized type. In addition, the expandable roller conveyor bears important weight. Moreover, there are rollers of different specifications and materials for choice. Of course, portable flex conveyor is generally only suitable for conveying goods with a flat bottom surface. If the bottom is soft, it’s better to use the belt conveyor.

Customization process of portable conveyor

1. Firstly, it needs to decide choose the skate wheel conveyor or collapsible roller conveyor. In addition, if choose the flex roller conveyor, it needs to choose “powered” or “unpowered”.

2. Secondly, it needs to know the basic sizes of the flexible expandable conveyor, such as “expanded length”, width and height. The height is usually adjustable. Most importantly, the price depends on the “expanded length”.

3. Thirdly, it needs to know the application and produce weight. So it can help us to confirm the material. Are there special working environment requirements (such as: humidity, high temperature, influence of chemicals, etc.)?

4. Finally, pls tell us if there are special requirements. For example, we can add the side bar on the flexible conveyor. In addition, it can also add the sensor onto the portable flex conveyor. For instance, when the item is transported to the tail of the conveyor, the sensor detects the item. At this time, the conveyor stops moving. When the items are taken away, the conveyor continues to run.

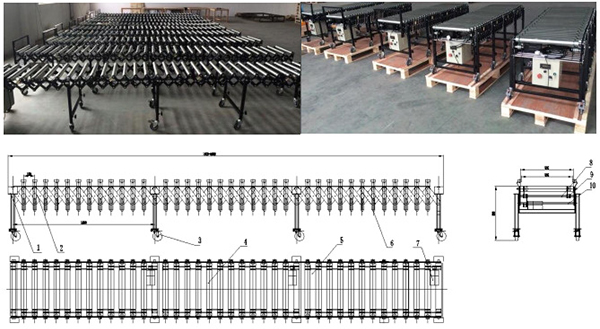

Case show & solution design

The following is an example of cigarette transportation in the tobacco industry. And the customer purchased 5 sets of flexible powered roller conveyor. The size of the smoke box is set according to 585(L)*460(H)*255(W). In addition, the weight of each cigarette is 17.5Kg/piece. The total length of the flex roller conveyor is 5000mm. It consists of 3 units. At the same time, the Max load of a single unit is 55Kg. In addition, the folded length of portable conveyor is 1700mm. The extended length is 5000mm. During working, length is adjustable from 1700 to 5000mm at will.

Structure of powered flex conveyor

|

No. |

Parts Name |

Notes |

|

1 |

Roller bracket |

Profile welding |

|

2 |

Roller support plate |

2.5mm thickness alloy stamping plate, electrophoresis surface treatment |

|

3 |

Casters(3 inches) |

Outsourcing standard parts |

|

4 |

Roller |

φ38mm O-slot galvanized roller |

|

5 |

O-belt |

PU round drive belt |

|

6 |

Guide wheel |

Optional according to user requirements |

|

7 |

Motor |

400W speed control gear motor |

|

8 |

Transmission shaft |

45# or stainless steel |

|

9 |

O-belt pulley |

Outsourcing standard parts |

|

10 |

Support shaft |

45# or stainless steel |

Accessories introduction of powered flex conveyor

Firstly, the roller bracket is the final force supporting component of the powered flexible conveyor. The selection mainly bases on the weight and size specifications of the transported items. In addition, it is welded with rectangular tubes. The material adopts Q235 surface spray treatment. Or use polished stainless steel surface.

Secondly, the support plate of portable conveyor is made of sheet metal parts. The material is Q235. Finally, it undergoes electrophoresis surface treatment. So it can enhance the corrosion resistance and strength of the expandable conveyor.

Thirdly, the casters use 3-inch heavy-duty silent wheels. The single carrying capacity is not less than 350KG. Besides, it’s with brakes. Therefore, the extendable roller conveyor is movable. Moreover brakes can increase its safety.

Immediately afterwards, it’s about roller types. There are many kinds of roller materials, such as carbon steel galvanized, 201 stainless steel, 304 stainless steel, PVC roller and so on. In the flexible roller conveyor, it usually uses three types, such as unpowered rollers, O-belt rollers and wedge-shaped belt rollers.

And then about the transmission parts, there are synchronous belts, ribbed belts, chains, O-belts and other transmission modes. For example, in the tobacco industry, the weight of the cigarette box is not large, so it can use the O-belt as the transmission part. PU round O-belt has extremely high tensile and tensile strength. Moreover, the O-belt is suitable for humid and dusty environments. In addition, it is also resistant to grease and chemicals.

Then, about the geared motor: use a well-known brand geared motor, 220V 50Hz. The noise is not more than 50dB. And the rotation is stable and reliable. In addition, it has overload protection and variable frequency adjustable functions.

Installation and debugging

Portable conveyor installation

Firstly check whether the packing case is complete. If there is damage, please give feedback in time. The flexible conveyor is easy to install. And it can also easily achieve telescopic length. Besides you can move the whole machine at any time. In addition, it can fold the flex conveyor after finishing transportation operation. So it saves storage space. It is very convenient to move the machine when the work location needs to be changed. Just release the brake and push it to the working place.

Trial run of flex conveyor

Firstly, it must ensure that the flexible gravity conveyor is not damaged. Before starting, check whether the voltage is 220V 50Hz (380V 50Hz). The deviation must not be greater than 5%. At the same time, check whether the wiring of conveyor is correct. For the first start, the time should not exceed 1 minute, and then stop. Check all parts for damage. If there is no failure, then start the second operation. And the duration is 5 minutes. At the same time, observe whether there is any abnormality. Finally, the third operation time of portable conveyor is not less than 30 minutes. At the same time, check whether the equipment is damaged. If not, enter the load trial operation stage.

Then, start flexible expandable conveyor without load. After the operation is stable, normal transportation can begin. Firstly carry out the experiment at one-third of the normal transportation efficiency. Observe the motor and conveyor parts for no damage. Then, start the normal transportation efficiency experiment. At the same time, observe whether the motor, conveyor belt, roller and other parts are damaged. Finally, test the portable conveyor according to the maximum shipping volume.

After completing the test according to the above steps, you can enter production. After one day of normal operation of the flex conveyor, then trial operation of the product is completed.

Extendable conveyor maintenance

Repair portable conveyor

The flexible conveyor has the following wearing parts, such as motor, O-shaped belts, rollers and skate wheels, etc. Different parts have different maintenance levels. Motor: Non-professionals are not allowed to disassemble. If there is any fault, please contact our company for repair and replacement. O-shaped tramission belt: it’s not easy to repaire. If damaged, replace it immediately. Roller: when the rotation is not flexible and the noise is loud, please replace the bearing. If it is deformed or cracked, please replace it immediately. Finally, if the skate wheel is damaged, please replace it immediately.

Flex conveyor maintenance

It needs to lubricate the bearings and moving parts of the flexible conveyor system regularly. Lubricate once a month. For powered flex roller conveyor, O-shaped belts are the most prone to wear during work. Therefore, when adding lubricating oil, please be careful not to drop the oil on the transmission belt. In order to prevent slipping and loss of rotation or premature damage to the belt.

At the same time, among the working parts of the powered flexible roller conveyor, the gear motor is an important component. It is strictly forbidden to run the gear motor without oil. And after the first 300 hours of operation, it should clean the inside of the machine and replaced with new oil. Thereafter, change the oil every 2500 hours of work. Therefore, it is necessary to pay more attention when maintaining the power portable roller conveyor.

Use precautions of flexible conveyor system

1. Firstly, choose a telescopic roller conveyor or skate wheel conveyor with a suitable width.

2. Secondly, check whether the expandable conveyor is abnormal. After confirming that it is normal, adjust the telescopic conveyor to a suitable length and a suitable conveying route.

3. Then after confirming that the conveying performance is normal, you can start conveying, loading and unloading goods.

4. When the skate wheel flex conveyor conveys goods, there must be someone at the other end of the conveyor to catch the goods.

5. After conveying the goods, check that there is no miscellaneous material on the conveyor, and then fold the extendable conveyor.

6. When shrinking the skate roller conveyor, firstly open the brake. Then it’s convenient to operate.

7. After folding the flexible gravity conveyor, place it in the spare area.

8. It can’t convey the goods exceeding the designed weight and volume. In addition, do not throw goods on the conveying surface. Avoid irregular operations that cause portable conveyor damage and affect transportation and production.

9. Regularly check the fasteners and do not loosen the parts. At the same time, check whether the conveyor parts are damaged, or whether there are sharp corners that will damage the goods.

10. Check the height of the support legs. If necessary, adjust the height to ensure that the casters are in contact with the ground. So it can ensure the conveying surface stable and the goods can move normally.

11. When it needs to stretch the telescopic portable conveyor into an arc, it should be stretched while bending. Never bend again when it has reached its limit.

Other precautions:

12. When expanding or folding portable expandable conveyor, pay attention to the injury of hands, clothes and other things. Operators with long hair should be rolled up. At the same time, it needs to fix the floating clothing corners to avoid being caught by the flex conveyor and causing personal injury.

13. Before closing or moving the expandable flexible conveyor, make sure that the brake of the brake caster has been released. When moving the portable conveyor, use the stop lever temporarily as a handle.

14. It needs to replace the damaged parts and components of the extendable conveyor in time.

15. Do not use the conveyor for a long time near the sea. Because seawater can easily corrode the conveyor.

FAQ

Q1: What is the expansion ratio?

A1: The expansion ratio is usually 3. If the expandable flexible conveyor is 9 meters long, the folded length is 3 meters.

Q2: What is the width and height of the telescopic conveyor?

A2: Standard height: 45~65cm/ 57~85cm/ 75~110cm/ 95~160cm/ 130~200cm;

Standard width: 500mm/ 600mm/ 800cm;

Both height and width can be customized according to specific requirements.

Q3: What is the load-bearing weight of the portable flex conveyor?

A3: The load-bearing capacity of the skate wheel conveyor is generally 80KG/m. And the load-bearing capacity of the expandable roller conveyor is 150KG/m. The smaller the spacing, the greater the load-bearing capacity.

Q4: How long is the warranty time of the portable conveyor?

A4: The warranty period is one year.

Q5: How many rollers does a roller conveyor have?

A5: Generally, a flexible roller conveyor has 10 rollers.

Q6: Can the telescopic roller conveyor be used for loading?

A6: Yes. It is best to use a flexible powered roller conveyor.