Showing all 2 results

Table of Contents

- 1. What is slat chain conveyor?

- 2. The structure and working principle

- 3. Specifications of tabletop chain conveyor

- 4. Introduction of slat chain belt

- 5. Features & advantages of flat top chain conveyor

- 6. How to select slat conveyor system?

- 7. The applications & cases of table top conveyor

- 8. How to install and use top chain conveyor?

- 9. Maintenance & troubleshooting of chain plate conveyor

- 10. Chain plate conveyor vs other conveyors

- 11. How to design slat chain conveyor?

- 12. FAQ

- If interested, please contact us~ Email: sales@custom-conveyor.com, Mobile/Whatsapp: +86-18030684383.

What is slat chain conveyor?

Different from other conveyors, the top chain conveyor uses a high-strength flexible chain plate as the conveying carrier. This slat chain is different from traditional chain. Because the chain has a continuous flat top surface, it is called table top chain conveyor or flat top chain conveyor. It composes of two basic parts: a hinged chain plate and a pin shaft.

The conveying surface of the flat-top chain conveyor is flat and smooth. Thus, the transition of materials between conveyor lines is smooth. So it is very suitable for conveying all kinds of glass bottles, PET bottles, cans, etc. It’s also namely bottle conveyor. Moreover, the flexible chain plate conveyor can not only convey in a straight line, but also turn and climb.

Types of tabletop chain conveyors:

1. Firstly, according to the width, it contains single-row and multi-row top chain conveyors;

2. Secondly, bottle conveyor has a variety of styles, such as straight type, turning type (90°, 180° and 360° circular), and inclined type.

3. Finally, it has a variety of materials, such as stainless steel chain plates (SS304 and SS420), plastic chain plates (POM material).

The table top chain conveyor line has many benefits, such as simple structure, convenient maintenance, beautiful appearance, reliable operation, and flexible layout. So slat conveyor belt has wide applications in many industries, such as the production lines of beverages, beer, food, pharmaceuticals, printing, cosmetics, electronics and other industries. In addition, it also often convey detergents, paper products, condiments, dairy products and tobacco.

The structure and working principle

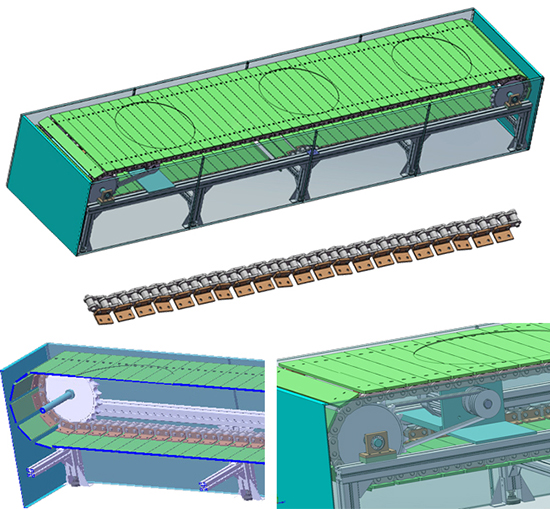

Structurally, the slat chain conveyor is similar to the conveyor belt system. Chain plate conveyor mainly includes the following parts, such as conveyor belt parts, support parts, motor drive system, tensioning mechanism, bracket and so on.

1. The table top chain conveyor structure & principle

-

(1) Conveyor belt parts

- The conveyor belt parts include two parts: one is table top chain, and another is chain sprocket. The conveyor sprockets includes a drive sprocket and a ider sprocket. The material is nylon. So it is resistant to high temperature, wear and corrosion.

(2) Support parts

The supports parts have two types: one is support strip, and another is guide rail. Among them, the support strip is suitable for straight top chain conveyor. On the contrary, the guide rail is applicable for curved flat top conveyor. Their raw materials are both ultra-high molecular polyethylene. The color can be green and black. The working temperature is -30°~90°. Together use with the slat top chain, it will reduce the coefficient of friction. Moreover, this kind PE conveyor support parts have other advantages, such as corrosion resistance, oil resistance, aging resistance, and good flexibility. They not only have a supporting role, but also have a guiding role.

(3) How does tabletop type slat conveyor work?

This tabletop conveyor realizes the conveying of goods through chain drive. That is to day, after the splicing of the chain slat, it will form a structure similar to a chain. Then it will realize transmission through the matching sprocket. When the flat top chain conveyor is running, it firstly engages with the living hinge of the slat chain through the sprocket. Then pull the chain to move forward. And the chain slat is placed on the guide rail and supported by both sides of the chain plate.

This is similar to the double-speed chain supported on the guide rail by rollers. The difference is that the double-speed chain rolls on the guide rail through rollers. On the contrary, the table top chain slides on the guide rail through the chain plate. The friction force of sliding operation is relatively large. Therefore, it is necessary to protect the chain and reduce the wear when the chain is running. So it is necessary to lay cushion materials between the chain plate and the guide rail, such as engineering plastics and stainless steel.

In order to meet the needs of different conveying speeds, it can change the gear ratio of the transmission sprocket. So it will change the running speed of the slat chain conveyor belt. In addition, when the flat top chain conveyor is running, there needs to be a certain amount of free movement between adjacent chain plates. There is a certain gap between adjacent slat chains to ensure that the chain will not interfere during operation. So this ensures the smooth operation of the top chain conveyor.

2. The heavy duty slat conveyor structure and principle

It composes of driving mechanism, tensioning device, drive chains, slats, driving and redirecting sprocket, frame, etc. Among them, the conveyor slats are fixed on the drive chains. Then a series of slats constitute the conveyor belt.

The chain bears the traction force of the conveyor. The slats act as a carrier for conveying materials. Pass the slat conveyor belt around the head sprocket and the tail redirection roller. Then the sprocket engages the drive chain. Finally it drags the conveyor belt to run continuously and cyclically.

Specifications of tabletop chain conveyor

1. Equipment name: slat chain conveyor or bottle conveyor;

2. Conveyor width: customizable (63mm~2000mm) (single row or multiple rows);

3. Conveyor length: customizable (usually not more than 40m for single drive conveyor line);

4. Machine type: straight, turning or curved, S-shaped, circular, climbing, spiral;

5. Conveyor belt material: plastic chain plate (POM), stainless steel chain plate (201, 304, 402);

6. Slat chain type: tabletop chain or flat top chain, anti-slip chain, fllexible plastic chain, mat top chain;

7. Frame material: stainless steel, aluminum profile, carbon steel, etc.;

8. Working temperature: -20℃~120℃ (the material of the chain plate is different, and the temperature resistance is different);

9. Conveyor speed: 0~20m/Min (speed adjustable);

10. Machine load: 5KG-3000KG / per meter (customizable);

11. Control mode: continuous working and intermittent working.

Introduction of slat chain belt

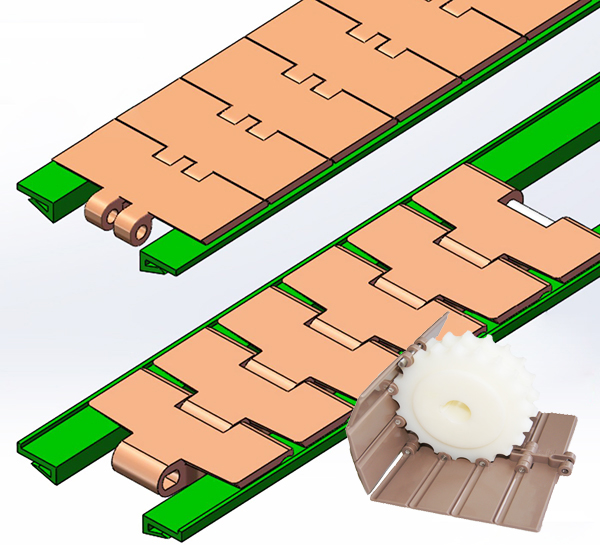

The structure of the flat top chain is very simple. Slat chain only consists of a chain plate with hinges on both sides and a pin. One side of the hinges on both sides is fixedly connected with the pin shaft (tight fit), which is called a living hinge. The other side is movably sleeved with another chain plate and pin shaft (clearance fit), which is called a fixed hinge. The movable hinge ring and the pin shaft constitute the hinge of the flat top chain.

The material of table top chain

There are three main materials for bottle conveyor belts, such as POM plastic, 2Gr13 stainless steel and SS304 stainless steel. They all have the characteristics of wear resistance and high toughness. The POM and 2Gr13 conveyor slat chains has wide applications in the industry. But the food industry and high-end packaging industry must use SS304 stainless steel table top chains.

1. Plastic slat conveyor chain:

It’s mainly applicable to all kinds of food, beverages, PET bottles, aluminum cans, and various containers. The slat chain material is made of POM and the color is brown. Applicable temperature: -40℃~ +90℃. The material of the pin shaft is: cold rolled austenitic stainless steel. Conveyor speed: 80 m/min (lubricant), 50 m/min (desiccant).

Firstly, the POM slat chain conveyor belt is thermoformed from plastic into a single-plate semi-finished module. Then assemble the modules into a chain type. Finally, install the POM table top chain on the bottle conveyor to carry and transport materials.

2. Stainless steel ss slat chain:

It is suitable for various glass and metal products. Most suitable for beverage and beer manufacturing industry. The stainless steel chain plate has the characteristics of high load, wear resistance and easy cleaning. Among them, the 2Gr13 conveyor slat chain is not corrosion resistant. Maximum speed: V (lubricant) ≤90 m/min, V (desiccant) ≤60 m/min. 1 meter = 26 pcs.

The working temperature of ss flat top chain is -20℃~+120℃. Firstly, stamp the semi-finished table top chain plate. Then fix parts by welding process. The hinge ring of the steel flat top chain is rolled. Finally, install the pin. So it finish production of ss slat conveyor chain.

The specification & types of slat conveyor chain

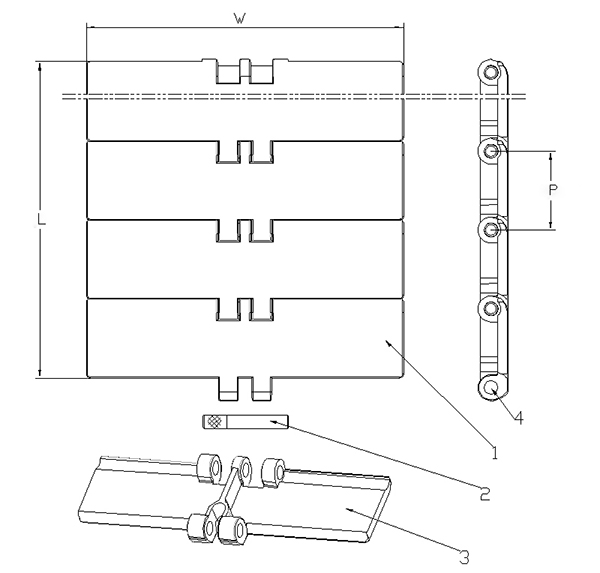

Width of straight chain plate: 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254, 304.8;

Turning slat chain width: 82.5, 114.3, 152.4, 190.5, 304.8.

W (width): horizontal unit of flat top conveyor belt;

L (length): the longitudinal unit of the slat conveyor belt;

1 : finished table top conveyor belt~loading surface;

2 : pins for assembly in 4 pin holes;

3 : modules, semi-finished products;

4 : pin holes, used to install 2 pins;

P (pitch) : it refers to the center distance of the two through holes of the module;

How to assemble the slat chain conveyor belt: firstly, repeatedly increase the module (3) to the required L (length); then put the pin (2) through the pin hole (4) and fix it in the 4-pin hole. Finally, connect the single chain plates in series into a long bottle conveyor belt.

According to the shape, the table top chain slat include several types, such as straight slat chain, turning chain plates, toothed chains, flexible chain, ball chain plates, etc. In addition, the bottle conveyor chain slat also include single hinge plates and double hinge plates.

Divided according to performance: anti-static slat chain, anti-skid chain plate, etc.

|

Slat Chain Type |

Tabletop Chain Model |

Pitch * Slat Chain Width |

Belt Thickness |

|

Stright Single Hinge Chain |

812-K250 |

38.1*63.5mm |

3mm |

|

812-K325 |

38.1*82.6mm |

||

|

812-K350 |

38.1*88.9mm |

||

|

812-K400 |

38.1*101.6mm |

||

|

812-K450 |

38.1*114.3mm |

||

|

812-K500 |

38.1*127mm |

||

|

812-K600 |

38.1*152.4mm |

||

|

812-K750 |

38.1*190.5mm |

||

|

Stright Double Hinges Chain |

802-K750 |

38.1*190.5mm |

|

|

802-K1000 |

38.1*254mm |

||

|

802-K1200 |

38.1*304.8mm |

||

|

Curved Flat Top Chain |

881TAB-K325 |

38.1*82.6mm |

|

|

881TAB-K450 |

38.1*114.3mm |

||

|

881TAB-K600 |

38.1*152.4mm |

||

|

881TAB-K750 |

38.1*190.5mm |

||

|

881TAB-K1000 |

38.1*254mm |

||

|

881TAB-K1200 |

38.1*304.8mm |

Note: 26 pieces per meter are standard. The pitch of each piece is 38.1mm. So the actual length of one meter slat chain is 990.6mm.

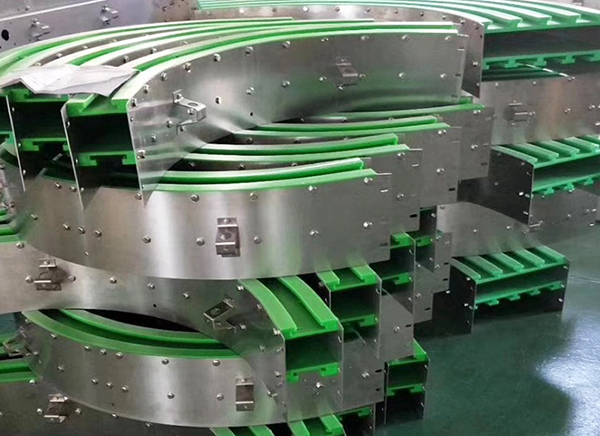

Curved flat top chain and conveyor

The gap between the slat chains of the ordinary straight bottle conveyor is very small. Therefore, this flat top chain can only run in a straight direction and cannot turn. However, in practical applications, the space of the workshop is often restricted. If adopts straight conveyor line, then it can’t realize the layout. For example, it is often necessary to use L-shaped, U-shaped or circular conveyor lines. At this time, if use the turning tabletop slat chain conveyor, it will greatly reduce the space requirement.

Why can it realize the turning function? The turning flat top chain conveyor develops from the basis of the straight flat top bottle conveyor. It only slightly changes the structure of the straight tabletop chain. On the one hand, increase the gap between the hinges. So it will form a certain bending angle between two adjacent slat chains plates. Finally, the sum of the bending angles of multiple chain plates can obtain a larger turning angle. On the other hand, design the hinge pin in a drum shape. It can also realize the turning effect. Curved slat chain conveyor often has a parameter called turning radius.

How curved slat chain conveyor manufactured?

The table top chain plates are connected in turn by pins. The middle part of the rear end surface of the flat top slat chain has a rearward lug. On the other hand, the middle of the front face has an inward groove. The shape and size of the groove are adapted to the lug. Both the lugs and grooves are on the same axis as the tabletop chain. The front and rear ends of each conveyor chain plate are flat shape. That is to say, the slat conveyor chains are generally rectangular.

However, the straight top chain bottle conveyor has the following shortcomings: the table top chain can only move in a straight line. That is to say, the top chain can only move along the axis of the bottle conveyor body. Therefore, when the conveyor slat chain needs to turn, the front and rear chains will collide with each other.

In order to solve this problem, it needs a curved conveyor slat chain. The turning tobble conveyor can not only move along a straight line, but also move along an arc within a certain curvature range.

The front end faces of each flat top chain are respectively curved surfaces protruding outward. On the other hand, the rear end surfaces of each table top chain are respectively curved surfaces descending toward the inward opening. Moreover, the curvature of the arc of the front and rear ends is the same. Therefore, when the bottle conveyor turns, the rear end face of the previous chains can still be in good agreement with the front end face of the next chains. And the slat chain conveyor can also move in a straight line like an ordinary top chain.

The curved flat top slat chain conveyor has the following benefits:

a. Eliminates the displacement structure when the bottle conveyor turns and changes direction;

b. During the conveying process, the items being conveyed are less likely to turn over or jump. The noise is also low;

c. Eliminate the sliding of the conveyed items at the turn;

d. Reduce the number of driving components such as motors, reducers, and sprockets.

Features & advantages of flat top chain conveyor

1. Firstly, the slat chain conveyor has good adaptability and economy. The conveying condition is stable and the turning radius is small. Low noise and low wear. And easy to clean and easy to maintain.

2. Secondly, the conveyor chain plate is resistant to high and low temperature, acid and alkali. Impact resistant and abrasion resistant. Table top chain is also antistatic and does not drop powder.

3. Thirdly, slat chain conveyor belt can generally be washed directly with water or directly immersed in water. So the conveyor equipment is easy to clean. Therefore, it can meet the hygienic requirements of the food and beverage industries.

4. The conveying surface of the slat belt is flat and smooth, with low friction. Therefore, the transition of materials between the slat bottle conveyors is smooth. Besides, the conveying speed is accurate and stable.

5. The flat top chain materials can be stainless steel and engineering plastics. A wide variety of specifications. So customers can select the tabletop chains according to conveying materials and process requirements. Thus it can meet the different indstries needs.

6. Flexible equipment layout. It can complete horizontal, inclined and turning tranportation on one conveying line. The bottle conveyor has a simple structure. So it’s easy to install, maintain and replace.

7. Flat Top chain conveyor is suitable for medium and heavy load transportation. Large load capacity and durability. Moreover, it has long service life. Because of the use of stainless steel and POM slat chain, they are strong and durable.

8. We can punch holes on the surface of the slat chain according to customer requirements. Install the fixture on the chain plate. So it can meet special transportation needs.

Other characteristics:

9. The table top slat chain conveyor is not prone to deviation of the chain plate. Firstly, the top chain plate and the sprocket mesh well. Then the sprocket drives the tabletop chain to drive. Moreover, the slat chain generally runs on the guide rail. The guide rail has a good guiding effect. Therefore, deviations do not often occur. Moreover, due to the modular structure, it is easy to disassemble and assemble. So it greatly reduce the conveyor maintenance cost.

10. The tabletop chain conveyor can not only operate continuously, but also work intermittently. Moreover, we can add sensors. Then this is beneficial for food or beverage manufacturers to realize multiple production types. As long as it is slightly adjusted, it can carry out different working modes. Therefore, it improves the production efficiency.

How to select slat conveyor system?

1. Firstly, inform the delivery conditions

(1) The material and surface condition of the conveyed object. Sometimes, there needs special chain plates, such as anti-skid slat chains and anti-static table top chains.

(2) The weight of the conveyed object. So we can determin the motor power of the slat chain bottle conveyor.

(3) The shape and dimensions of the conveying object. This can help determine the width of the flat top chain plates. Besides, it can help us to know whether to use a single-row slat chain or a multi-row top chain.

2. Secondly, confirm the delivery conditions

(1) The length of the top chain conveyor. The length of the slat chain conveyor can be very long. However, generally the control length of a single motor should not exceed 40m.

(2) Transmission speed, interval between transmission objects, and load status. The speed is different, the motor power is also different. At the same time, it also needs to inform whether the motor is adjustable.

(3) Whether there is detention (detention on the conveyor).

(4) Whether the chain transmission surface is lubricated.

3. Then, confirm the transportation path

(1) Use a straight conveyor or a curve conveyor. This needs to consider the layout of the workshop. Of course, we usually use the straight slat chain conveyor and curved flat top conveyor together. This can solve the space problem.

(2) It needs to know whether it is horizontal conveying or inclined conveying. If it is an inclined table top chain conveyor, you also need to know the overall height.

4. Afterwards, consider the use environment and the goods characteristics

(1) Conditions such as temperature, humidity, moisture, and oil content;

(2) The cleanliness of the installation location and surrounding

(3) Corrosion resistance, chemical resistance and oil resistance of flat top slat chains, sprockets and slide rails;

These determine the material of the bottle conveyor. SS stainless steel slat chain has a heavier load than plastic chain plates. Impact resistance and abrasion resistance are also better.

5. Finally, choose the right conveying amount

Before buying a chain conveyor, you must firstly know the output of your products. Then choose the table top chain conveyor with the right conveying amount according to the output. When selecting the conveying capacity of the slat chain conveyor, be sure to choose a model larger than the output of the conveyor.

So how to calculate the conveying capacity of the flat top chain conveyor? The calculation method is: density × volume × speed / hour. This is the throughput per hour. Then multiply it by the working time to get the total throughput. Finally, combine your own output to choose the appropriate tabletop chain conveyor. Because the speed of the bottle conveyor can be adjustable, it is often calculated that the conveying capacity is 1.2 times the selected output.

The normal conveying speed of the table top chain conveyor should be controlled at 0-20 m/min. If you think the conveying efficiency is low, it is best to solve it by increasing the width of the bottle conveyor. It is not solely for the sake of increasing the speed of the conveyor. Because if the conveying speed is too fast, the precision ratio requirements of the slat chain and sprocket are very high. Then it will cause the flat top chain plate to jump teeth and cause losses.

The applications & cases of table top conveyor

Except for items with extremely high viscosity, both general solid materials and finished products can be transported by table top chain conveyors. Flat top chain bottle conveyors are mainly used in automated production, transportation, distribution and packaging in many industries, such as food, medicine, beverage, daily chemical products, paper products and other industries.

The following are some application cases of slat chain conveyors:

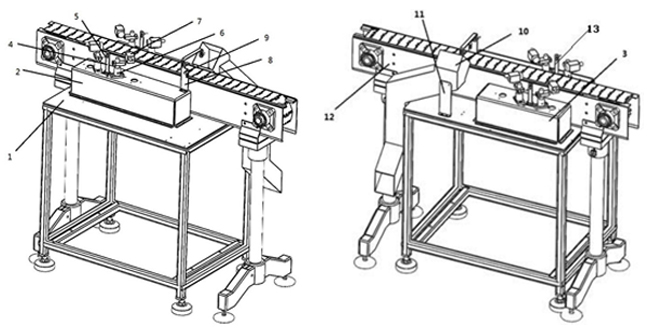

1. A visual inspection and conveyor equipment for bottles

1-frame, 2-long-platform, 3-short platform, 4-fiber sensor bracket, 5-fiber sensor, 6-vision camera bracket, 7-vision camera, 8-integrated bracket, 9-air nozzle, 10 -guide pipe, 11-guide pipe support, 12-slat chain conveyor; 13-sensor.

The vision camera can adapt to the high-speed operation of bottle products in the production line. At the same time, it can meet the quality inspection of mass products. A visual inspection bottle conveyor equipment came into being. Its application is not limited by the size, shape, use environment and other factors of bottle products. This bottle slat chain conveyor can not only save a lot of labor costs, but also ensure its inspection precision.

What’s structure of this bottle conveyor?

The visual inspection conveying device is installed on the frame (1). Firstly, there are table top slat chains on the bottle conveyor (12) to transport bottles. Secondly, fix the long platform (2) and the short platform (3) respectively on the frame on both sides of the flat top conveyor (12). Then, fix a pair of vision cameras (7) on the platform through the vision camera brackets (6). Afterwards, fix the optical fiber sensor (5) in the middle of the two vision cameras (7) on the same side through the optical fiber sensor bracket (4). The optical fiber sensors (5) on both sides face each other.

At the other end of the long platform (2), there fix the sensor (13) above the slat chain through the bracket (8). The sensor (13) illuminates the surface of the flat top chain vertically downwards. An air nozzle (9) is installed on the bracket (8). The air nozzle (9) is connected to the high-pressure air and points vertically to the transmission direction of the slat chain bottle conveyor. The other side of the table top chain is used to fix the guiding pipe (10) through the bracket (11). The inlet of the guide pipe (10) is opposite to the gas nozzle (9). The optical fiber sensor (5) and the sensor (13) are connected with the computer. After the sensor receives the signal, it feeds back to the computer. In this way, the operation of the vision camera (7) and the opening and closing of the gas nozzle (9) are controlled.

How does this kind visual inspection slat chain bottle conveyor work?

When working, the bottles are placed on the feeding side of the slat chain conveyor (12). Flat top chains drive the bottles moving. When moving to the fiber optic sensor (5), the fiber optic sensor (5) detects the bottle. Then feedback the signal to the computer. The computer controls the four vision cameras (7) to turn on and quickly detect the information of the bottle. The signal may be the information on the label of the bottle, whether the bottle is dirty or the size of the bottle. Finally, the test results are transmitted back to the computer for analysis. From this, it can judge whether it is a qualified product or not.

The bottle continues to move via the slat conveyor chain. After leaving the optical fiber sensor (5), feedback the signal to the computer. The computer controls the four vision cameras (7) to temporarily shut down. When the bottle moves to the sensor (13), for qualified products, the computer will control not to trigger other devices. Then the qualified product will continue to enter the next process. But for unqualified products, they need to be selected. At this time, the computer will control the gas nozzle to spray high-pressure gas to the unqualified bottle. Then blow the unqualified bottles to be selected into the guide pipe (10). Then the unqualified products are collectively collected at the end of the guide pipe.

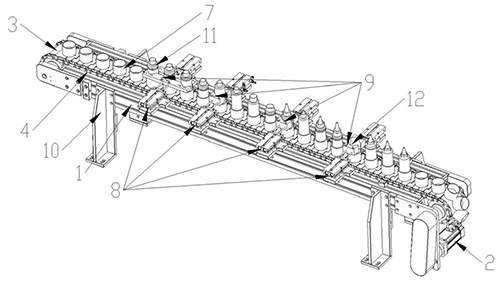

2. Ink bottle slat chain conveyor with fixture

During the automated production process of ink products, it is necessary to use a slat chain conveyor to convey the ink bottle to each station for ink filling, film welding, and capping operations. However, when placing the ink bottle on a traditional bottle conveyor for transportation, the bottle is prone to shaking, shifting or even toppling. This causes the bottle to be misaligned with the working ends of each station. Therefore, sometimes it is necessary to align the bottle body manually. So it is troublesome.

In the picture, we set several positioning fixtures (7) on the slat chain conveyor belt at intervals. The ink bottle fits in the groove of the fixture (7). This avoids the problem of displacement and dumping of the ink bottles during the conveying process. At the same time, it can also realize the precise alignment of the bottle and the working end of each station.

How to install and use top chain conveyor?

It should clean all parts of the flat top chain conveyor before installation. And check it carefully. Then transport the individual components to the installation site. In fact, the installation of the slat chain conveyor is similar to other conveyors.

1. Firstly, determine the center line of the table top slat conveyor according to the drawing. The center line is the basis for installing the bottle conveyor. Then, along the center line, determine the center position of the head sprocket shaft and the tail sprocket shaft.

2. Secondly, based on the above centerline, determine the position of the following parts of the table top slat conveyor, such as the position of the frame, the installation position of the guide rails, and the center position of the driving device in the vertical and horizontal directions.

3. Thirdly, install the bottle conveyor brackets (including the head brackets, tail brackets, middle bracket and drive unit bracket) in sequence. Then install the guide rails. Furthermore, install other parts, such as the driving sprocket device, the tail sprocket device, the tensioning device and the table top slat chains.

4. Finally, install the drive device and guardrail brackets.

How to use the table top conveyor rightly?

1. Firstly, before turning on the slat chain conveyor, check the various parts, such as the driving device, sprockets, chain plates, etc. Make sure they are firm and reliable.

2. Secondly, check whether the lubrication of each part meets the specified requirements. If the requirements are not met, it should add lubricating oil.

3. The starting sequence of the flat top chain conveyor: open the material receiving equipment firstly. Then start the table top conveyor. Finally, start the feeding equipment.

4. Please feeding evenly during the top chain conveyor working. Too much material is easy to block and flow out of the machine. Besides it will cause the chain plate derailment accident. At the same time, it will damage the motor.

5. In addition, it should check the tightness of the slat chains frequently. And make adjustment at any time if necessary. Deflection of uneven force is not allowed to occur.

6. If any failure occurs during the operation of the slat bottle conveyor, please shut it down immediately for inspection and maintenance.

7. When shutting down, please stop the feeding equipment firstly. After there is no material on the tabletop chain conveyor, stop the conveyor.

8. Finally, be sure to keep the slat chain conveyor clean and hygienic.

Kind note: when the flat top chain starts to run, it should ensure that there is no materials or goods on the slat conveyor. Because the acceleration required when starting up is quite large, if there is material on the chain plate, problems such as gear slippage and excessive motor load may occur. When the multi-stage table top chain conveyors are running, the power-on sequence should be the last stage firstly, and then forward in turn. The shutdown sequence is reversed.

Maintenance & troubleshooting of chain plate conveyor

During the operation of the bottle conveyor, some problems may also occur. We must learn to distinguish and resolve.

Slat conveyor chain belt deviation

When the table top chain belt deviates at the head and tail, it is generally because the sprocket device has a deflection angle. The simple solution is to adjust the tension shaft on which side the chain plate runs off. Then the pulling force on the side of the chain plate that deviates is greater. So the flat top chain will move to the side with the smaller pulling force.

If the deviation is serious, it needs to be re-checked. Make the parallelism of the center line of the driving and driven sprockets meet the requirements. If the deviation occurs due to the error in the processing of the sprockets, then it needs to remove and reprocess them.

Slat chain belt slipping phenomenon

Whether it is a belt conveyor or a flat top chain conveyor, they must be under tension during the conveying process. As long as it is under tension, it will definitely cause the slat belt to be stretched. Over time, it will cause the tabletop chain to slip. What’s more, it will cause the chain plate and the sprocket to separate.

Solution: Adjust the tensioning mechanism. Tightening the screws will increase the center distance between head and end sprockets. Thus, it can tension the slat chain belt.

In addition, the load of the slat conveyor belt is too large. It will also slip when it exceeds the capacity of the motor. At this time, the advantage of slipping is to protect the motor. Otherwise, the motor will be burnt after a long time.

Bottle conveyor has abnormal noise

Reasons and solutions:

1. The drive chain is in contact with the protective cover or frame, etc.;

——Confirm and correct the touched part.

2. The guide gap of the guide rail is narrow. So the table top chains can’t run smoothly;

——Smooth finishing on the surface of the guide rail. Or change the size again.

3. Overload operation;

——Please ensure that the conveying weight cannot exceed the design requirements of slat chain conveyor.

4. Insufficient lubrication.

——Sufficiently lubricate all parts to ensure that they operate smoothly.

Rust on stainless steel ss slat chain

Reasons: Firstly, we need to understand the characteristics of the stainless steel flat top chain materials. There are mainly two kinds of ss table top chain, namely 2Gr13 and SS304 material. 2Gr13 is also called martensitic stainless iron. Its rust and corrosion resistance are not as good as SS304. Therefore, if the production environment is humid or corrosive such as acid and alkali, it is best to use SS304 material slat chain.

So how about the anti-rust effect of SS304 slat conveyor chains?

The stainless steel ss 304 slat chain plate has the ability to resist atmospheric oxidation-that is, non-corrosion. At the same time, it also has the ability to resist corrosion in media containing acid, alkali, and salt—corrosion resistance. The key reason why SS304 flat top conveyor chain has rust resistance is because it contains chromium. Under the effect of corrosive medium, chromium will form a solid and dense oxide film on the surface of top chain, which is also namely “passivation film”. This film isolates the tabletop chains from the external media and prevents the slat chains from being further corroded. So under normal circumstances, ss304 slat chain will not rust.

But if improper use or maintenance, or the environment is too harsh, stainless steel table top conveyor chain may rust. For example, the surface of the tabletop chain has metal dust or particles. In the humid air, the condensed water between the attachment and the stainless steel slat conveyor chains connects them to form a micro battery. This initiates an electrochemical reaction. Then it will destroy the protective film. It is called electrochemical corrosion. If the surface of the stainless steel bottle conveyor slat chain adheres to acids, alkalis, and salts, it will cause local corrosion. In addition, in the polluted air (such as containing a large amount of sulfide, carbon oxide, nitrogen oxide, etc.), it will form sulfuric acid and acetic acid liquid spots when encountering condensed water. This will cause chemical corrosion of the flat top chains.

Suggestions and solutions:

1. It must clean the surface of the stainless steel bottle conveyor slat chain plate frequently. Remove attachments. So as to eliminate the external factors that cause corrosion.

2. In addition, it should use SS316 stainless steel tabletop chain in coastal areas. Because 316 material can resist the corrosion of seawater chloride ion.

What is the quick way to remove the rust spots on the surface of the stainless steel slat chain conveyor? Firstly, apply the pickling paste on the surface of the stainless steel table top chain. If the temperature is below 0°C or the oxide layer is relatively thick, you should extend the time appropriately. During the operation, it is best to scrub with a brush several times. After the oxide layer on the outer surface of the flat top chains is completely removed, rinse it with clean water (lime water or alkaline water is better). Prevent rusting again.

Chain plate conveyor vs other conveyors

There are many kinds of conveying equipments. So how do we know whether to choose a flat top chain conveyor or other conveying machines? The key is to understand the difference between them.

Table top chain bottle conveyor vs belt conveyor

- 1. Different applications: Both of them can be suitable for light load transportation and heavy load conveying. However, belt conveyors are more commonly applicable in light-load applications. The slat chain conveyor is more commonly used in heavy-duty occasions.

In addition, conveyor belt materials are different. So the belt conveyor can convey powder or loose materials. But the slat conveyor cannot do it. The table top chain conveyor is often used to transport bottled or canned products.

Furthermore, belt conveyors often has the belt deviation phenomenon. On the contrary, flat top chain bottle conveyors rarely have this phenomenon. And the chain plate is more suitable for harsh working environments. So the maintenance cost of the top chain conveyor is lower.

2. For the belt conveyor, there is no relative movement between the material and the conveyor belt. So the noise is low. The noise of the top chain conveyor will be slightly louder. Due to the materials, the price of the tabletop chain conveyor will be slightly more expensive.

3. Different working principles: In fact, both of them convey goods through the friction of the conveyor belt. The working principle of the belt conveyor that the head roller drives belt to run under a certain frictional force. But the working principle of bottle conveyor is as follows: Firstly, combine the flat top slat to form the structure of the chain. Then, the slat chains meshes with the sprocket. Finally, the motor drives the sprocket to move. The sprocket drives the tabletop chain to transport the items.

Flat top chain bottle conveyor vs chain conveyor

As a kind of chain conveyor, free flow chain conveyor is also namely double speed chain conveyor. It has many similarities with slat conveyor. But the former is rolling friction. The latter is sliding friction. Moreover, the double-speed chain conveyor cannot achieve turning. However, the flat top chain conveyor can turn. In addition, the maintenance cost of the table top chain conveyor is lower. Finally, the applications are also different. The free flow chain conveyor mainly acts as a conveyor assembly line for electronics, home appliances and other products.

How to design slat chain conveyor?

Q1: Can we buy the slat conveyor parts separately?

A1: Sure. We can supply & customize most slat chain conveyor components, such as table top chain, sprocket, guide rails, brackets, motor, etc.

Q2: How long is the warranty period of your flat top chain conveyor and motor?

A2: Two years. If the tabletop bottle conveyor has any quality problems within 2 years (only product problems under normal operation), we will replace the motor and related accessories free of charge (including the freight).

Q3: What to do if I don’t know how to install a table top chain conveyor?

A3: Sometimes, the conveyor length is very long. At this time, in order to facilitate transportation, customers often need to assemble them by themselves. Of course, we usually install the conveyor step by step. Ensure that the machine can operate normally. And record the video and send it to the customer. Then disassemble the slat conveyor and pack it before shipping.