Showing all 4 results

Table of Contents

- 1. Introduction of small portable conveyor belt

- 2. Specification and category

- 3. Features & advantages of miniature conveyor

- 4. How to choose mini conveyor system

Introduction of small portable conveyor belt

The micro belt conveyor has a reasonable structure design. It is especially suitable for occasions that require space optimization. So it has wide application in various automation equipments, such as vending machines. Small conveyor belt system can control the start, stop and transportation of workpieces. Besides, you can use it together with robotic arms and sensors. Miniature conveyor belt generally have a lighter load. Generally, the weight of conveyed products is about several kilograms. In addition, if there are higher requirements for space, we can use DC direct motors. And internal built-in DC motor.

Specification and category

1. Belt width: 10mm, 20mm, 50mm, 60mm, 100mm, 150mm, 200mm, 250mm, 300mm, 350mm, 400mm, etc;

2. Belt types: general purpose, food grade, cleated belt, oil-resistant belts, heat-resistant belts, anti-static belts, slope non-slip belts, ribbed anti-deviation belts, modular belts, slat chain, etc.;

3. Frame material: aluminum profile (anodic oxidation treatment), aluminum plate, painted steel and stainless steel plate, etc.;

4. Motor: geared motor, direct DC motor, stepper motor, servo motor, etc. In addition, speed controller is available.

4. Transmission direction: both one-way and two-way transmission can be customized.

5. Other accessories: brackets (stands), sensors, aviation plugs. Among them, there are many types of sensors. Some can be used for counting. Others can control the start and stop of the conveyor belt. In addition, the aviation plug can meet the requirements of plug and unplug.

6. In addition, we process the mounting holes on the small belt conveyor. So it will be convenient for customers to use.

The category of mini conveyor belt

Firstly, there are many types of mini belt conveyors. Secondly, it needs to choose a specific model according to your needs. It is best to contact us to customize the personalized micro conveyor.

According to the shape of the conveyor, it contains many types. For example, the head drive mini conveyor. Intermediate drive micro belt conveyor. Top bracket small conveyor belt. Also, a belt conveyor with a internal built-in motor. Double-row miniature conveyor (namely timing belt conveyor). Full belt conveyor. Narrow belt conveyor. Small cleated conveyor belt, etc.

Firstly, head drive short conveyor belt is the most basic model. Moreover, it has the largest load-bearing capacity.

Secondly, for the middle drive type, it can adjust the tension in the middle part.

Thirdly, the double-row timing belt conveyor: adopts the method of motor + synchronous belt drive. So it can realize the synchronous conveying of two rows of timing belts. Suitable for pallet transfer.

Then, the cleated conveyor is suitable for equidistant conveyance and inclined conveyance of small workpieces.

In addition, narrow belt conveyors are suitable for use in small spaces.

Then, the conveyor with built-in motor: The motor is internal between the profiles to control the height of the small belt conveyor.

Besides, there is a kind of MDR (motor driven roller) belt conveyor. It uses the electric roller to replace the motor. So it can also optimize space. But the Min roller length is usually 200mm. Thus, it’s not suitable for the narrow belt conveyor.

Finally, a full belt conveyor means that the entire conveyor belt surface can act as a transport surface.

Features & advantages of miniature conveyor

(1) Low price: Due to the rational structure, our mini conveyor belt can be provided at a low price. Thereby it reduces costs for customers.

(2) Diversity of choice. We can customize a variety of small conveyors. So it can meet a variety of needs. Moreover, itcan install the photoelectric or optical sensors on the short conveyor. Therefore, this can better realize automatic control.

(3) Short delivery time. If there are 5 sets of micro conveyors, the delivery time can reach 5~7 days.

(3) Most of the parts and components in our conveyors can be purchased individually. So customers can have more options for designing and maintaining miniature conveyors.

(4) We can customize mini belt conveyor with a unit of 10mm or 5mm. Therefore, customers can easily choose the desired size.

(5) The main body of small conveyors is mostly made of aluminum profiles or plates. Thus, it realizes the lightweight of the whole machine.

(6) In addition, we can place nuts on the conveyor frame in advance. Or machine threaded holes in the plate. So it is convenient for customers to install other parts.

(7) Besides, the speed is adjustable. And the belt tension is also adjustable. The structure is simple, so the maintenance is very convenient.

(8) Finally, the mini belt conveyor has a natural advantage in the transportation of small pieces. Therefore, it is very common in the transportation of some small packages and small items. Small belt conveyor runs smoothly and has low noise. Besides, it can achieve up and down transportation.

How to choose mini conveyor system

In order to customize the small conveyor belt system, it needs to confirm the following details:

1. Firstly, please advise the type of miniature conveyor. You can refer to the above content. The mini conveyor belt has a variety of shapes and specifications. For example, if have strict requirement for space optimization, it’s belt to use the small belt conveyor with internal DC motor. For instance, if incline conveyor, it had better to use the small cleated conveyor belt.

2. Secondly, it needs to know whether you need the stand (support legs) and the side guards.

3. Thirdly, pls tell us the specific size of micro conveyor. For example, it must to know the conveyor length and belt width. In addition, if you have requirement for overall height, please advise it.

4. Fourthly, you need to tell us the application and goods weight. Because different applications, different belt and frame materials to use. Moreover, different goods weight, different motor power to use. Of course, the mini belt conveyor is usually suitable for light-duty items.

5. In addition, it had better to tell the conveying speed. The speed is usually 0~10 meters per minute. Besides, does the conveyor speed need to be adjustable?

6. Finally, are there any other requirements? For example, some customers require a counting function, then it can add sensors.

-

The belt application and materials:

- (1) Firstly, if it is general use, you can choose PVC belt. Its temperature resistance range is -30~80℃.

- (2) Secondly, if food conveyor, it needs food grade belt, such as PU belt (Polyurethane material) and PE belt (Polyethylene material).

(3) Thirdly, if inclined conveyor, it can use the non-slip textured conveyor belt. Because it can increase friction, it is suitable for climbing transportation. In addition, you can also choose the mini cleated conveyor belt.

(4) Fourthly, if you want to prevent the belt from deviating, you can choose a ribbed conveyor belt. Of course, the supporting plate used at this time must have a guide groove. So they can be used together.

(5) In addition, if it is oil-resistant or heat-resistant application, you need to choose PU belt or NBR rubber belt. Of course, canvas or Teflon belt can also withstand high temperature. It needs to inform the specific temperature.

Small conveyor motors

The selection of the motor depends on the weight of the load and the conveying speed. If it is a geared motor, we generally use high-quality mainland China brands or Taiwanese brands. If it is a DC motor, we generally use the Zhengke brand. Of course, you can specify which brand of motor to use.

In addition, if you need precise position positioning, you can choose a stepper motor or a servo motor.

Among them, DC motors are the cheapest. Then the price of the speed regulating motor is moderate. Finally, stepper motors and servo motors are the most expensive.

Conveyor installation and disassembly

Small belt conveyors are generally modular in design. So it’s very simple to install and disassemble. In addition, knowing the operation process is crucial to how to maintain the miniature conveyor.

How to install (assemble) mini conveyor belt?

-

1. Firstly, install the support legs (stands).

- Place 2 sets of H-shaped brackets on the open floor. Then, install the adjustable foot onto the stands. After installation, you need to measure the height with a tape measure. To ensure that each bracket is in the same horizontal position. Finally, fix the profile to the two legs with screws. So the final small belt conveyor will not shake.

2. Secondly, assemble the conveyor belt.

The conveyor belt is already connected well. Above all, set the support plate into the mini conveyor belt. Then, put the active roller and the driven roller in sequence. Afterwards, fix the 2 sets of guide rails on both sides. Finally, install the belt onto the stands. Importantly, it must use a tape measure to check whether the conveyor diagonal lengths are the same. Otherwise, it is easy to cause belt deviation. It will also affect the life of miniature conveyor belt.

3. Thirdly, install the small conveyor belt motor.

Above all, install the motor support plate. Then install the motor onto the support plate. Afterwards, install the sprockets. Install 1pc on the driving roller. And mount the other piece on the output shaft of the motor. It must check the lengths with a tape measure. Make sure that the two sprockets have the same length. If the length is different, it will damage the micro conveyor. Then, install the chain. Finally, mount the speed governor and connect it to motor.

4. Finally, assemble othe accessories and test mini belt conveyor

Sometimes, it needs to install other accessories, such as sensors, side guides, etc. Afterwards, you need to adjust the belt tension. If the belt is too loose, the friction is not enough. Therefore, the micro belt conveyor cannot work normally. At this time, you can start to test the mini belt conveyor. Check whether the small conveyor belt is operating normally. At the same time, see if there is any belt deviation. If so, adjust it in time. When testing the miniature conveyor belt, run for a few minutes without load. Then put the products to test.

How to replace the miniature conveyor belt?

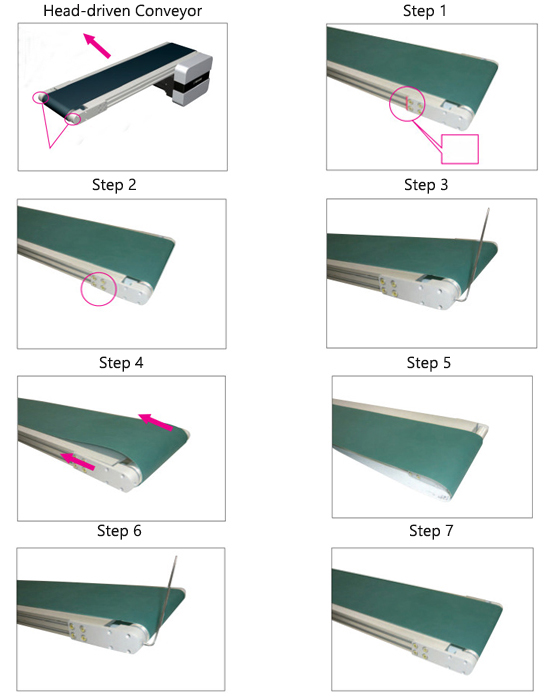

Replace the belt of head-driven micro conveyor

1. Firstly, for this head-driven mini conveyor, the conveying direction of the belt is specified. So when replacing the belt, please pay attention to the arrow on the back of the belt and the conveying direction. The arrow in the figure shows the direction of belt removal. In addition, the red at the end shows the belt tension adjustment screw.

2. The first step is to make a mark (as shown in the picture). Thus we can understand the belt tension. At the same time, it also needs to mark the opposite side.

3. Afterwards, loosen the 4pcs screws slightly. These 4pcs screws are used to fix the pulley holder. Be careful not to loosen the screws completely. Otherwise, the pulley will fall. At the same time, loosen the 4pcs screws slightly on the other end.

4. Loosen the tension adjustment screw of the small conveyor belt. And take it off. Same operation to the screw on the other end.

5. Put the pulley fixing seats on both sides to the side of the main body of conveyor

6. Confirm the belt conveying direction. Then replace the belt.

7. After replacing the mini conveyor belt, tighten the tension adjustment screws on both sides. Make sure that the tensioning position is exactly at the position marked in the Step 1.

8. Finally, install the 4 screws on the 2 sides respectively. And tighten them. In this way, it completes the entire belt replacement process.

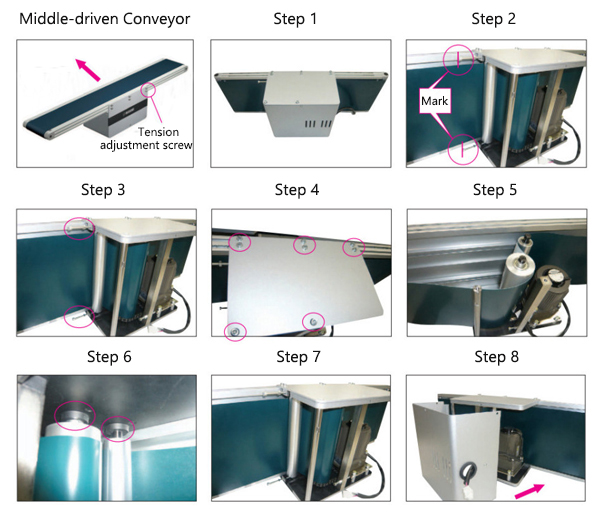

Replace the belt of middle-driven small conveyor system

- 1. Different from the head-driven miniature conveyor belt, the middle-driven mini conveyor has tension rollers at the bottom. Of course, it is also necessary to clarify the conveying direction of the belt (as shown in the figure). You can view the back of the belt.

- 2. In the Step 1, firstly turn the driving device of the small conveyor downward. Then remove 6 screws. Then remove the cover.

- 3. Make a mark in order to understand the belt tension.

4. Remove the 2pcs tension adjustment bolts. Pull out the tension adjustment roller.

5. Afterwards, loosen the 8pcs bolts of the side panel. Then remove the side panel of the micro conveyor.

6. Pull out the belt upwards. Confirm the belt conveying direction. Replace it with a new belt.

7. After replacing the belt, cover the side panel from above. At this time, please confirm that the two roller shafts have entered the holes in the side panel. Finally, install the side panels well.

8. Insert the tension adjustment roller. It is necessary to ensure that the 2pcs tension adjustment bolts are reset to the positions marked in step 2.

9. Finally, pass the wiring into the wiring hole. Then install the housing in the direction of the arrow. Tighten the 6 bolts. At this time, it completes replacing belt of small conveyor.

Calculation of conveyor belt length

Firstly, it need to be clear about related concepts. The belt length generally refers to the circumference of the belt’s median diameter (the center of the belt thickness). Not the circumference of the belt’s inner or outer diameter. When tensioning, the actual deformation of the belt is very small. Therefore, when designing the mini belt conveyor, it usually doesn’t consider the influence on the belt length while tensioning.

Generally, the length of the mini conveyor belt=2*roller center distance +1/2*driving roller circumference+1/2*driven roller circumference. But when the tensioning mechanism is in different positions, the belt length of small conveyor is different. For example, when it is at the loosest position of the belt, the belt length (L2) is the shortest. Because the the roller center distance is the shortest at this time. On the contrary, when it is in the tightest position of the belt, the belt length (L1) is the longest. Because the roller center distance is the longest at this time.

Therefore, in order to ensure that the belt still has a certain adjustment range, the belt design length (L) is generally designed as follows: L=L1+1/2*(L2-L1).

Troubleshooting of micro conveyor

Although mini conveyor belt are simple in structure and stable in performance, they generally do not have big problems. However, it also needs good maintenance during use. The common problems of small belt conveyor are belt deviation and slippage.

Deviation tolerance: The distance between the two sides of the roller and the belt is 5±3mm. During operation, there is no guarantee that the belt will always be in the middle of the aluminum profile. Belt deviation is not a quality problem. Deviation adjustment is part of the routine maintenance of the miniature conveyor belt.

Belt deviation is the most common fault during the operation of small belt conveyors. It will cause many bad effects. For example, the belt will rub against the side plates or guide rails. Therefore, if the time is long, it will cause the belt to wear or break. Secondly, the belt deviation increases the axial force that the rollers bear. This causes damage to the roller. In serious cases, it will cause the micro conveyor to stop working. This will affect production efficiency.

How to adjust belt deviation of miniature conveyor belt?

1. Firstly, run the small conveyor with the belt running to one side. Use the tension adjustment screw on that side to adjust the deviation. Take care to avoid contact between the belt and the side.

2. Then, loosen the fixing nut on the tension adjustment screw. Tighten the tension adjustment screw gradually. Over-tightening will deflect in the opposite direction. In this case, loosen the screws.

3. Finally, correct the belt deviation. Make it parallel. Re-tighten the loosened nut. After adjustment, run the mini belt conveyor directly for a short time. Make the belt run stably.

How to adjust the tension of the flat mini conveyor belt?

The appropriate tension of the flat small conveyor belt depends on several factors, such as the structure of the micro conveyor, the material, and the weight of the conveyed items. For specific adjustment, please refer to the following methods.

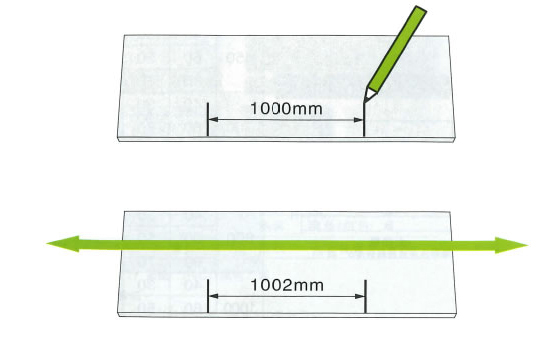

1. Firstly, choose a length of 1000mm. Mark the inconspicuous parts of the flat small conveyor belt.

2. Secondly, tighten the flat belt slowly until the marking line reaches 1002mm.

3. Drive the flat mini conveyor belt in this state. And check if the flat belt is slipping. (If the flat miniature conveyor belt is snaking, please adjust). After confirming that there is no problem, carry out the transmission test. If the transmission is smooth, you can continue to use it. If it slips after placing the items, go to next step.

4. When the flat micro conveyor belt slips, please tighten it slightly. Every time you need to confirm the slippage, until the flat belt does not slip. Adjust the snake and conduct a transmission test. Use it after confirming that the transmission is smooth.

5. It is recommended to check the tension state regularly.

Use and precautions

When using the mini conveyor, it must operate correctly. You can refer to the following instructions.

-

1. Precautions for safe use

(1) Before using micro conveyor:

You need to read the instruction manual carefully before using the small belt conveyor. Ensure the safe and correct use of the miniature conveyor.

·When moving the conveyor, please handle it carefully. Prevent the machine from slipping and causing you injury. In addition, pay attention to the balance of the conveyor when transporting by crane.

·Fix the small belt conveyor before use.

·In order to prevent electric shock, the ground wire must be connected. It must install a circuit breaker on one side of the mini conveyor belt.

·Please check before use.

·Adjust the belt tension before use.

(2) Precautions when using miniature conveyor

It can’t use the mini conveyor system of our company for moving or conveying people.

The conveyor cannot be used in the following environments:

a) Water environment (no waterproof design);

b) An explosive environment (a place with gas or natural gas, dust)

Do not touch the moving parts while the conveyor machine is running. Install safety protection device when necessary.

The motor part will be hot during the operation of the small belt conveyor. So do not touch it to avoid burns.

Use the micro conveyor according to the carrying capacity.

Be careful not to get clothes and hair into the conveyor during use.

Excessive impact can cause damage to the conveyor machine.

Forbid touching electrical parts with wet hands to avoid electric shock.

Not to disassemble or modify the conveyor. Otherwise, it will affect its performance and functions.

Perform maintenance on the machine with the power supply cut off.

When replacing the mini conveyor belt, please pay attention to the conveying direction. (The conveying direction of some belts is specified).

Please don’t start the small belt conveyor under load, so as not to burn the motor due to overload.

Don’t overtighten the belt. At the same time, avoid excessive wear of the belt.

Use a belt suitable for the object to be transported.

Inspect all the bolts of the miniature conveyor every year. (Because the vibration during operation will cause the bolts to loosen).

2. Mini Conveyor Belt Maintenance

It must cut off the main power supply before maintenance.

Prohibit apply excessive tension. When the belt is too tight, continuous use of the small belt conveyor will cause premature aging of the belt and damage to the pulley shaft.

Adjust the belt deviation in consideration of the belt tension.

If it is a mini conveyor with anti-running ribs, please do not let the ribs come into contact with the pulleys and aluminum alloy profiles during adjustment.

Clean it carefully before running the conveyor machine.

When adjusting the belt tension, make fine adjustments alternately left and right.

If you only tighten the tension adjustment bolt on one side, the belt will quickly deflect to one side. Therefore, contact between the belt and the pulley holder or the guide rail will cause the belt to wear or tear.

Application cases of mini belt conveyor

FAQ

-

1. About the small belt conveyor system

-

(1) Why is the miniature conveyor not working?

- The conveyor does not work due to the following reasons:

- 1) It may be that the goods weight exceeds the maximum load capacity of the mini belt conveyor. Because the load is too heavy, it will cause too much contact between the belt and the support plate. Thus, the motor cannot drive the micro conveyor belt to run. At the same time, long-term overload operation can easily damage the motor.

2) Please confirm whether the power supply (socket, control panel power supply) is turned on.

(2) Why the mini belt conveyor has abnormal noise?

- 1) The timing belt or chain of the driving part may be too loose or too tight. If so, it needs to adjust the timing belt or chain.

- 2) It may be caused by belt wear. If the belt back is severely worn, replace it with new one.

- 3) There may be scratches or something attached to the pulley or idler. Need to remove it.

- 4) It may be the noise of the motor. Check whether the motor is damaged.

(3) Can we adjust the small conveyor belt system to reverse operation?

- If the mini conveyor you bought is one-way operation, it is not recommended to adjust it. Of course, you can order a two-way conveyor.

(4) If I want to convey a slightly heavier item, is there any method?

- As mentioned above, when the product weight exceeds the conveyor load, the small conveyor system will not operate. But can we solve it? It can consider replacing the motor with a higher power. In addition, you can also consider replacing the transmission gear. Because of the change in the number of gears, it changes the reduction ratio of the motor accordingly. Thereby improving the transportation capacity of the mirco conveyor. However, the speed of the belt will drop accordingly. Therefore, it is necessary to consider whether it meets the requirements.

-

2. About the small conveyor motor

(1) What kind of motors are available for choice?

- We can match different motors with different conveyor requirements. Commonly used mini conveyor motors include direct DC motors, geared motors, stepper motors and servo motors. In addition, the warranty period of our motors is one year.

(2) How long is the lifetime of your motor?

The lifetime of our motors can exceed 10,000 hours.

3. About the small conveyor belt

(1) Are your conveyor belts strong?

Sure. Our mini conveyor belt adopts the tooth connection method by hot melt machine. It can ensure that the conveyor belt is not easy to break.

(2) How to distinguish between PU belt and PVC belt?

PU belt and PVC belt are the two most commonly used conveyor belts in mini conveyor system. But they are very similar in appearance. The following are two ways to distinguish:

Compared with PVC conveyor belts, PU conveyor belts feel a little harder to the touch with hand. Besides, after folding in half, look at the elasticity of the small conveyor belt. PVC conveyor belts rebound slower, while PU conveyor belts rebound faster.

In addition, the smoke produced by burning the PU conveyor belt is white. But the smoke generated by burning the PVC conveyor belt is black, and there is a lot of smoke. The PU mini conveyor belt has less odor when burning, and becomes a black viscous liquid after burning. However, the PVC small conveyor belt has a strong odor when burning, and becomes hard material after burning.