Showing 1–6 of 8 results

Table of Contents

1. Gas / electric conveyor pizza oven

At present, conveyor belt pizza ovens are widely used in various pizza shops. It can set the time and temperature. Therefore, everyone can bake the pizza. Moreover, pizza can achieve the same taste. So pizza conveyor greatly reduces the operating intensity of employees. There is no need to train employees too much. Just put the pizza in from one side and take it out from the other to produce it.

(1) What is a conveyor oven?

Because this oven looks like a small conveyor furnace, it is also namely conveyor belt pizza oven. Different from traditional kilns and layer furnaces, it uses conveyor belts to transport pizza from one end to the other.

During the entire conveying process, it uses high-temperature pressurized jet baking technology. That is to say, there is hot air blowing at the pizza above and below. Therefore, the hot air quickly penetrates the inside of the pizza. Finally, the pizza is heated more evenly. So the taste is better.

What can you cook in a conveyor oven?

The belt conveyor oven is professional for pizza kitchen commercial use. In addition to baking pizza, you can also bake other foods. For example, you can use it to bake bread, fish, chicken, steak, sausage, burger, french fries, biscuits. Pizza conveyor can also be used for barbecue.

Of course, in order to ensure the baking effect, the food entrance height of the pizza oven is often not high. So it does not apply to all foods.

|

Food Category |

Status |

Baking Time(min) |

Baking Temperature(℃) |

|

14” thick Pizza |

Fresh |

7 |

249 |

|

12” Pizza |

Pre-baking |

4 |

214 |

|

Sea bass 6oz./pc |

Frozen |

6.5 |

218 |

|

Chicken breast |

Frozen |

6.5 |

232 |

|

Cheese sandwich |

Fresh |

2 |

260 |

|

Hamburger (6oz. meat pie) |

Raw material |

6.5 |

218 |

|

Fries (3oz.) |

Frozen |

5.5 |

260 |

|

Sausage |

Raw material |

5 |

218 |

|

Biscuit |

Frozen |

6.5 |

204 |

Note: The above data is just a reference. The specific baking time and temperature base on the specifc conveyor belt pizza oven.

(2) How does a conveyor pizza oven work?

In order to know the working principle of the pizza tunnel oven, we need to understand its structure firstly.

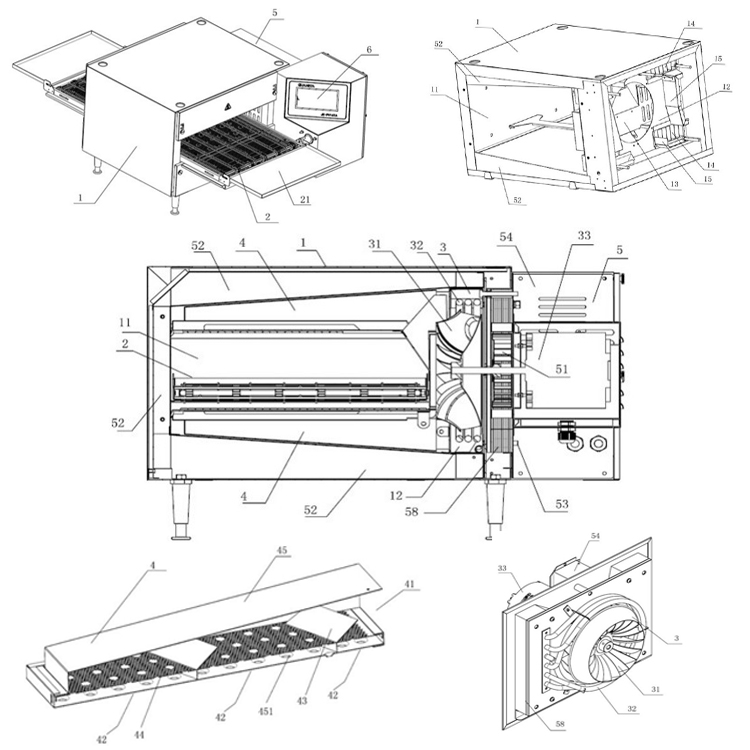

(1~Pizza oven shell, 2~conveyor belt, 3~wind direction converter, 4~air guide channel, 5~cooling and heat insulation system, 6~control system, 11~inner cavity of oven, 12~wind direction conversion cavity, 13~air inlet, 14~ exhaust outlet, 15~ deflector baffle, 21~ cover plate, 31~ impeller, 32~ heating tube, 33~ motor, 41~ air inlet, 42~ air outlet, 43~ air guide plate, 44~ filter, 45~ shell, 451~ exhaust hole, 51~ blade, 52 ~ cavity zone, 53~ air inlet, 54~ air outlet, 58~ heat insulation board. )

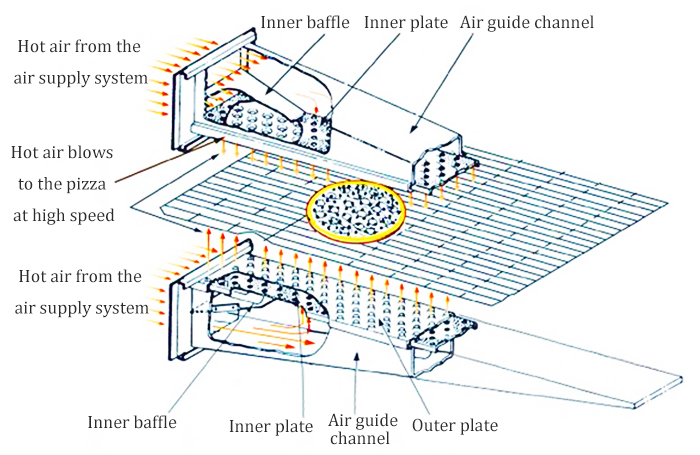

The heating tubes are arranged around the periphery of the fan blade. The oven has a unique internal structure. Firstly, the heating tubes heat the airflow. Then the upper and lower air guide channels guide the hot air flow to form vertical convection. Therefore, a hot air circulation system forms in the conveyor pizza oven. Moreover, the pizza oven uses a hollow stainless steel mesh belt. Therefore, the airflow can pass through smoothly. So the working temperature is more uniform and the heat is fully utilized.

Air impingement principle: There are many exhaust holes on the air guide plate. So the inner and outer plates in the upper and lower air guide channels form the airflow into jet-like hot air. The jetted hot air is distributed above and below the conveyor belt where the pizza is placed. Then the fan sucks hot air into the return air passage. So it forms a cycle.

(3) Features of conveyor belt oven

① The hot air jet technology effectively locks the moisture in the pizza. So it make pizza taste more fresh and delicious. And the heating is even. Besides, the cooking are fast, stable and standard.

② Due to the conveyor belt, it can automatically transport the pizza to the oven for baking.

③ Because of rigorous electronic temperature control, it can achieve a good effect of baking pizza. Moreover, the conveyor oven can control the cooking time. So it simple to operate. It can greatly improve work efficiency.

④ Easy to clean. The wind deflector, air guide channel and conveyor belt can be quickly removed for cleaning. Besides, oven installation is also simple.

⑤ The outer shell and liner panel use food-grade stainless steel materials. Beautiful, hygienic and practical. In addition, it can also be stacked in multiple layers.

(4) How to use / apply the pizza conveyor?

Turn on:

Firstly turn on the power switch. After setting the temperature, press the heating start button. Immediately afterwards, put the prepared pizza on the conveyor mesh belt. Then set the baking time. After setting the conveying speed, turn on the conveyor operation switch. At this point, the pizza starts to bake automatically.

Shutdown:

Firstly turn off the heating switch. After the temperature drops, turn off the thermostat again. Finally, turn off the power switch.

Precautions:

① When putting the pizza in the conveyor oven, pay attention to not putting it too densely. Don’t let out the space outside the belt, so as not to squeeze or fall the product. In addition, it is forbidden to bake flammable, explosive and corrosive items.

② When it is necessary to observe the baking situation, you can observe it through the oven door glass. But don’t open the door, so as not to affect the constant temperature. Especially when the temperature of the baking zone is above 200°C, opening the door may cause the glass damage.

③ For pizza conveyor with hot air circulation, the air supply motor must be kept on during the heating and constant temperature process. Otherwise it will affect the uniformity of the temperature in the baking area. Then it will damage the heating components.

④ Please place the pizza belt oven in a dry and level place to prevent vibration and corrosion.

⑤ For electric conveyor pizza oven, pay attention to safe use of electricity. Install a power disconnect switch with sufficient capacity according to the rated power of the oven. Besides the oven must be connected to a good grounding wire.

⑥ For the gas conveyor pizza oven, the store needs to maintain circulating fresh air convection to ensure sufficient oxygen in the gas combustion air.

(5) How to clean pizza oven conveyor belt?

After the baking, we must clean and maintain it. Of course, turn off the power firstly. After the pizza belt oven has cooled down, we will start cleaning. In addition, we also need to know how to disassemble and install the pizza oven.

Disassemble conveyor pizza oven

① Firstly, unscrew the screws and remove the drive chain cover. Then disassemble the covers at both ends of the conveyor belt and the tray under the oven belt.

② Secondly, lift the conveyor belt slightly. Then disassemble the drive chain.

③ Drag the pizza oven belt and find its joint. Then use a screwdriver to pry the connectors and remove them one by one. Note: The joints need to be placed uniformly to prevent loss.

④ Roll up the entire pizza conveyor belt for cleaning.

⑤ Then move the frame of the conveyor belt out of the pizza oven.

⑥ Next, remove the adjustable baffles on both sides of the oven one by one.

⑦ Then take out the air duct from the oven chute one by one.

⑧ Finally, disassemble all the outer panels (the side with holes) of the air duct for easy cleaning.

Install conveyor belt pizza oven

① Firstly, install the cleaned air guide duct to the upper and lower chutes of the pizza oven in turn.

② Secondly, the installation principle: accessories removed later must be installed first. Install adjustable baffles at both ends of the oven.

③ Thirdly, install the pizza conveyor belt. Pass the pizza oven belt around the sprocket at one end. Then drag until it bypasses the sprocket at the other end. (Note: the smooth side of the conveyor belt is facing up). Next, connect the conveyor belts with joints. Finally, pull it to confirm whether the movement is smooth. Be patient when installing the conveyor belt.

⑤ Next, put the installed conveyor belt into the pizza oven. Then install the drive chain.

⑥ Finally, install the chain protection shell. Then, install the covers and pallets at both ends of the pizza conveyor belt. At this point, the assembly work is complete.

Clean pizza oven

Soak the disassembled accessories in hot water. Then pour the detergent. After soaking enough, scrub again. The amount of cleaning agent can be adjusted according to the amount of water. Never use aggressive cleaning agents. Otherwise, it will damage the life of conveyor belt oven. And it’s not healthy for food baking.

Then, clean the body and main part of the pizza conveyor. Clean up the food residues in the oven first. Then, cover with detergent and moisten it, allowing enough time to act on the dirt. Then scrub with a scouring pad. Finally, wipe with clean water repeatedly.

Tip: You can tie a wet rag with a wooden stick. Then scrub the places out of reach.

(6) Troubleshooting for conveyor belt pizza oven

There may be some problems when the pizza conveyor is running. You can refer to the following steps to try to solve it. If there is a problem that can be solved, please contact us.

① Can’t turn on the pizza belt oven

Reason: The power source may not be connected to the oven. Or the controller setting is incorrect.

Solutions: Firstly, check whether the air switch or fuse blower switch turn on.

Secondly, check whether the switch of the blower is “On”. Because only the blower switch turns on, the heating element will heat up.

② The pizza tunnel oven can’t heat up

Reason: Maybe the controller setting is incorrect.

Solutions: Firstly, check whether the temperature setting is correct.

Secondly, check whether the blower development turns on.

Thirdly, if the pizza oven still cannot heat up, turn off the blower switch and conveyor belt switch.

③ The pizza belt oven can work. But the wind blowing from the air duct is too small or there is no wind.

Reason: After cleaning, the assembly of the air duct may be incorrect.

Solution: Firstly, turn off the conveyor oven and wait for it to cool. Then turn off the power.

Secondly, follow the instructions to reassemble the air duct.

④ Pizza conveyor belt is unstable or does not run at all

Reason: The conveyor belt may be jammed by some objects in the oven. Or the tightness of the oven belt is not enough.

Solution: Firstly, turn off the oven and wait for it to cool. Then turn off the power.

Secondly, check if there are any objects jamming the oven belt.

Thirdly, adjust the tightness of the conveyor belt.

⑤ Pizza is over-baked or under-baked

Reason: incorrect setting

Solution: adjust the baking temperature and time

2. Tunnel IR / UV Conveyor dryer screen printing

Conveyor dryers have wide application in the printing industry. It includes silk screen conveyor dryer and uv curing oven. The former usually uses IR infrared heating. Unlike other industries, the baking temperature of tunnel dryer screen printing is often not high. We often use it to dry clothing, T-shirts, leather, electronic components, food, pharmaceuticals, etc.

(1) What is screen printing conveyor dryer

It is also namely tunnel dryer or belt furnace. The tunnel dryers are special for the curing inks on various materials. IR drying tunnel oven can drying most all kinds of ink ( except UV ink). For example, it can cure thermosetting ink, screen printing ink, pad printing ink, plastic ink, glass ink, etc. Of course, uv curing oven dry the UV ink.

Screen conveyor dryer usually uses the infrared heating method. Screen printing tunnel dryer can be suitable for many kinds of materials, such as fabric, paper, cardboard, plastic, metal, glass,wood, silicone. For instance, we usually use tunnel conveyor oven to dry t shirt after printing. In addition, because the drying temperature is often not high, it usually uses Teflon mesh belt and PVC conveyor belt.

On the other hand, UV curing oven is a machine that uses a UV light source to cure UV coatings. It reacts chemically with the photosensitizer in the UV coating. So it can instantly dry and solidify the ink or glue. The core component of conveyor curing oven is the UV lamp. It can use high-pressure mercury lamps, metal halide lamps or LED lamps. The equipment has wide application in the curing of glue after dispensing products in the glass, electronics, and 3C industries. For example, the mobile phone screen panel is cured with a UV dryer. Unlike traditional hot air curing, UV curing oven is more efficient.

(2) How does screen printing conveyor dryer work?

Similarly, in order to understand the working principle of screen tunnel dryer, we must first understand its structure. The screen tunnel dryer usually consists of heating tubes, wind motor, impeller, belt conveyor and a control system.

Multiple infrared heating tubes are installed on the cover of conveyor oven. The mesh belt conveys the printed products to the drying working zone. When screen tunnel dryer starts to work, the wind motor will drive the impeller to rotate. So it makes the hot air blow to the belt. Then it will dry the printed matter that has passed. Since the hot air flow is evenly distributed in the working zone, the drying effect is very good.

The working principle of uv curing oven

UV curing is a technique for obtaining a coating film through the rapid polymerization of a monomer/oligomer mixture. This drying is achieved using photoinitiators and high-performance lamps. The UV tube lights up and emits ultraviolet light with a main peak of about 360nm. Then, UV light irradiates the ink layer to cause the acrylic resin of the ink to crosslink and cure.

(3) Technical Specifications of Mesh Belt Dryer

|

Item |

Parameters of Conveyor Oven for Screen Printing |

|||||

|

Size |

Whole Conveyor Dryer (L×W×H) |

1.88×0.7×0.85m |

2.5×1.3×0.85m |

3×1.3×0.97m |

4×1.3×0.97m |

5.5×1.3×0.97m |

|

Heating Zone(L×W) |

100×65cm |

170×65cm |

200×65cm |

300×65cm |

440×65cm |

|

|

Mesh Belt Width |

650mm (custom) |

|||||

|

Entrance & Exit Height |

150mm (adjustable) |

|||||

|

Conveyor Belt |

Belt Material |

Teflon (stainless steel mesh belt and PVC belt are also available) |

||||

|

Conveying Speed |

1~5m/min (speed adjustable) |

|||||

|

Motor |

200W |

200W |

400W |

400W |

750W |

|

|

Heater |

Heater Type |

IR Infrared Lamps |

||||

|

Distance from heating tube to conveyor belt |

10cm |

|||||

|

IR Lamps Quantity |

8 pcs (custom) |

12pcs (custom) |

15pcs (custom) |

15pcs (custom) |

28pcs (custom) |

|

|

Power |

Voltage |

220V / 380V (custom) |

||||

|

Whole Machine Power |

4.8KW |

7.2KW |

9KW |

9KW |

16.8KW |

|

|

Temp. |

Heating Temperature |

0~250℃ |

||||

|

Weight |

Whole Mesh Belt Dryer (G.W.) |

200KG |

250KG |

400KG |

480KG |

550KG |

(4) Features of screen printing dryer machine

① Firstly, you can adjust the speed of the conveyor belt. Therefore, it can adapt to the needs of different products. At the same time, the conveyor dryer can realize forward and backward transportation.

② The input and output ends of the drying oven are with sliding doors. And you can raise or lower them. Therefore, it can effectively shield the heat source from leaking. At the same time, it is convienet for drying products of different sizes.

③ The tunnel dryer screen printing uses the thermal circulation system. So it can uniformly heat the product and speed up the drying. At the same time, shorten the drying time and save energy.

④ Due to the intelligent temperature control system, it can effectively control temperature deviation. At the same time, you can set the drying temperature and time by yourself. The control panel will display the temperature and time.

⑤ There are many types of conveyor belts to choose from, such as Teflon mesh belts, stainless steel mesh belts and PVC belts. Different dryer belts are suitable for different temperatures. So it can meet a variety of temperature requirements.

(5) How to use screen printing tunnel dryer?

In fact, it is simple to operate the infrared mesh belt dryer.

Basic operation of printing conveyor oven:

① Firstly, check whether the power supply is well connected;

② Next, open the door of electric control box. And then turn on the air switch.

③ Thirdly, turn on the power switch, and the power indicator light is on.

④ Then, start the wind motor and heating switch. At this time, the thermostat will light up and display the temperature. Of course, you can set the temperature according to your printing ink drying requirements.

⑤ Immediately afterwards, press the switch of speed controller. And the mesh belt starts to run. You can set running speed of the conveyor belt freely.

⑥ It’s best to test your printing products first. After debugging the optimal temperature, baking time and running speed, then start batch printing and drying.

⑦ Shut down conveyor dryer after drying. Turn off the heating switch first. Then open the door for cooling. After 5 minutes have passed, turn off the conveyor motor and wind motor switch. Finally, close the main switch.

Precautions:

① The tunnel furnace must have a good grounding wire.

② When handling the fault, the operator must first turn off the power. In order to avoid accidents caused by the wrong operation of the machine.

③ The tightness of the conveyor belt should be appropriate. At the same time, it needs adjust belt tightness at any time.

3. High Temperature continuous heat treatment tunnel dryer

In industrial production, it is often necessary to heat and dry products. High-temperature treatment on the surface of the workpiece to achieve curing. At present, most continuous tunnel dryers have several areas, such as loading area, heating area, cooling area and unloading area. There is a mesh belt conveyor in the drying furnace. It conveyors the workpiece for heating. Then transport to the cooling zone for cooling treatment. All processes are automatically completed at one time. The operation is simple, so it saves labor cost.

(1) What is continuous tunnel dryer?

Tunnel furnace adopts hot air circulation and far-infrared method to dry products. Industrial conveyor oven is mainly to meet the high-yield drying needs. The tunnel oven is a continuous drying equipment. It can continue to bake uninterruptedly, thereby improving production efficiency.

The advantage of mesh belt oven resides in the fact that it is a continuous heating furnace. Therefore it does not require that the pieces to be heated remain stopped. Due to its great versatility, tunnel dryer with conveyor has multiple applications.

Tunnel dryer can be used for drying and baking in industries such as food, textiles, and small die-casting parts. Or use it to dry painted workpieces. In addition, conveyor belt oven is also applicable for continuous drying and sterilization of zitter bottles, cosmetic bottles, pharmaceutical glass bottles, Chinese medicine and other materials.

Some specific application examples:

① There are a large number of rectifiers in automotive electronic products. The fixing and installation of the rectifier is generally like this: Firstly, apply the flux and solder. Then heat them at high temperature in industrial tunnel oven.

② After completing first impregnation, the solid capacitor needs to be put into the drying furnace to dry the water vapor. Then carry out the second impregnation.

③ In the home appliance industry, phosphating film acts as the bottom layer of electrophoretic coating and has been applied almost 100%. After painting, we need put them into a tunnel conveyor dryer for drying.

④ High temperature heat treatment is required in the metal industry. For example, we need to put the spring in a continuous tunnel dryer for heating. This significantly improves the performance and service life of the spring.

(2) Tunnel Dryer Working Principle

The tunnel furnace plays a role by heating tubes. Firstly, heater converts electrical energy into thermal energy. Then the heat is blown into the air inlet duct and conveyor oven by the fan. This forms a hot air circulation.

Generally, it uses far infrared to heat the furnace. IR rays can reach every corner of the conveyor furnace. The internal hot air circulation makes the upper and lower temperatures in the tunnel dryer more uniform. So it can ensure product baking quality.

(3) Features & Advantages of Continuous Tunnel Dryer

① First of all, precise temperature control system: PID control, with temperature self-tuning function;

② Secondly, conveyor oven adopts SSR solid state relay output. Therefore, it can achieve control according to the size of the temperature deviation.

③ Thirdly, infrared heating system: circulating air design, uniform temperature at all points inside;

④ In addition, the temperature can be controlled in sections. Therefore, our tunnel dryer can adapt to product demand. High flexibility.

⑤ The hot air with large air volume circulates in the oven. So it can be used to dry various materials;

⑥ Conveying system: adopts frequency conversion speed regulation. Then you can adjust dryer belt speed according to needs. Therefore, it can always maintain smooth operation.

⑦ The conveyor dryer can be connected to the production line for synchronous control and reduce defects.

⑧ Finally, it can add an exhaust pipe to reduce pollution.

(4) How to use & operate conveyor tunnel furnace oven?

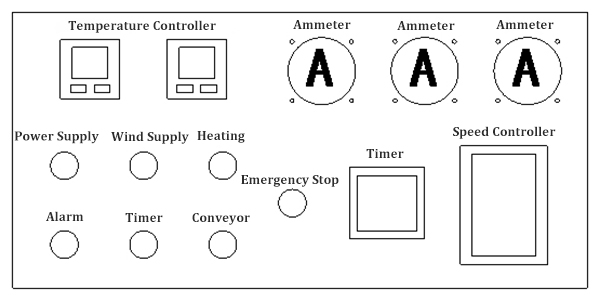

Control Panel of Industrial Conveyor Dryer

Power source: display the power status of conveyor furnace. After turning air switch, the light stays on.

Temperature control: control and display the temperature in the tunnel furnace dryer. It can be controlled in two sections before and after.

Emergency stop switch: suitable for emergency situations. It can cut off the power supply of working electrical appliances, but not the main power supply. The power indicator light is still on.

Speed controller: adjust the speed of the conveyor dryer belt.

Conveyor: choose whether to turn on the conveyor belt.

Timer: control the transmission time of the conveyor belt. When time is up, the conveyor oven belt stops. At the same time, the alarm sounds.

Start and stop of wind motor: After pressing, the indicator light is on. The wind motor works. At the same time the heating switch can be activated. After pressing it again, the wind motor stops working. At the same time, the infrared tube goes out.

Heating start: After pressing, the indicator light is on. And the infrared lamp of tunnel dryer is on.

Current meter: displays the current of each section.

Tri-color indicator light: When the product flows to the exit of the tunnel dryer, the detection switch detects it. Alarm prompt. At this time, the yellow light flashes. When the temperature of the tunnel conveyor oven exceeds the set temperature, alarm prompt. At this time, the red light flashes. Green light is normal status.

Operation Steps of Tunnel Conveyor Oven

① Turn the air switch to the “ON” position. Turn on the main power supply. At this time, the power indicator light is on.

② When starting up, first press down the conveyor control switch. Press down the wind switch. Then press down the heating switch. Tunnel furnace enters the drying state.

③ When stopping, press heat switch and the conveyor switch in sequence. Then press emergency stop. The continuous tunnel dryer stops working.

Debugging Steps of Conveyor Furnace

① Connect to electricity

Three-phase five-wire system (3-phase 380V). Firstly, Connect live wire to the main power switch. Then connect neutral wire to the neutral wire position. Finally connect the ground wire. After power on, press the wind motor switch of tunnel dryer. Check whether the running direction of the wind motor is consistent with the direction indicated by the arrow label. Otherwise, switch the positions of two of the live wires.

② Adjust the conveyor belt

Adjust the rotating terminal on the speed controller. Then it can change the transmission speed of the dryer conveyor belt.

③ Adjust the temperature of conveyor furnace

The thermostat can set the drying temperature. In addition, the actual temp. of drying zone is often different from the set temp.. Therefore, we need to use a thermometer to measure the actual temperature at the sensor. If the difference is large, we need to re-correct the tunnel dryer temperature according to actual needs.

(5) Troubleshooting of conveyor tunnel dryer

During the process of using the conveyor oven furnace, we will encounter various problems. Here is a summary of the causes and solutions of some common problems.

Conveyor belt does not move

① Check the circuit. Measure whether the working voltage of the motor is normal

② Check whether the motor or inverter is damaged. The VFD can refer to the manual. If damaged, please send it back to the factory for repair.

The heating tube does not light up

① The power supply lacks phase. If so, several lamps usually do not light at the same time. At this time, measure whether the input 3-phase voltage is normal. Or check the lamp circuit of tunnel dryer.

② The lamp tube is damaged. At this time, we need to replace the heating tube.

4. Food microwave drying oven

Conveyor microwave oven is a device that uses electromagnetic waves to heat materials. It is to splice several furnace bodies together. Then it forms the tunnel microwave oven. It is industrial microwave equipment. In addition to the drying effect, microwave tunnel dryer can also sterilize. So it has wide application in industrial mass production.

This microwave drying oven becomes popular for heating, drying or sterilizing various products in the food, chemical, and furniture industries. After dyring & sterilization, the food shelf time can be extended by 3 to 8 times.

(1) How does tunnel microwave conveyor oven works?

When the tunnel furnace is in operation, the microwave generator produces microwaves. Then, the conveyor transports the material to the microwave heating cavity. At this time, the moisture in the material is heated to evaporate. In addition, the dehumidification system discharges water vapor to achieve the purpose of drying. Moreover, the bacteria in the material will also be killed. Due to the microwave electromagnetic field, biological and thermal effects will occur. So microwave tunnel dryer has a bactericidal effect.

(2) Characteristics of microwave conveyor dryer

① Fast drying speed;

② Heat and dry evenly;

③ Keep the original color of the material;

④ High energy saving efficiency;

⑤ Simple operation and large selectivity;

⑥ Easy to realize automatic assembly line production;

(3) The correct operation process of microwave tunnel dryer

① Firstly, check whether wire connection are normal.

② For tunnel dryer, check the tension of the conveyor belt. Because after a long period of production operation, the oven belt may loosen.

③ Then, turn on the transmission system and the fan cooling electrical part. Observe whether there is any abnormality in the unit of the microwave conveyor oven and the heat dissipation system.

④ When the power on, it should be idling for a short period of time. After normal operation, then add materials onto microwave conveyor dryer.

⑤ Technicians should always pay attention to the changes in the value of the instrument. If the value fluctuates abnormally, press and hold the emergency stop button of the device immediately.

⑥ When finishing work, cut off the power first. Then clean up the microwave drying oven.

5. Comparison of several tunnel conveyor ovens

Understanding the characteristics of different baking equipment will help us make better choices. Next, we will introduce the comparison of drying ovens.

(1) pizza conveyor oven vs deck oven

For deck oven: This type of oven is the most common. Many pizzerias use deck oven. This kind of oven uses the upper and lower fire to heat up. It takes a long time to bake. In addition, you need to flip the pizza constantly.

Pizza baked in a deck oven has a lot of moisture. It is easy to cause the pizza bottom to separate from the cheese. Especially for fruits or ingredients with high water content. This kind of oven is easy to dry and burn the pizza. Besides, the heating is uneven. So it will affect the taste. Of course, deck oven is cheaper than conveyor toaster oven.

For conveyor pizza oven: It uses high temperature pressure jet baking technology. The hot air quickly penetrates the inside of the pizza. So it makes the heating more even and the taste is better. Moreover, you can easily adjust the temperature and time of pizza tunnel oven according to your own needs.

During the baking process, no need human intervention. We just need to wait for the pizza to come out from conveyor pizza oven belt. The whole process is simple and efficient, saving time and effort.

(2) conveyor dryer vs drying oven

For drying oven: it usually means the industrial vertical dryer. The product placement method is generally tray push or push rack push. Drying oven occupies a small area. Compared with the tunnel conveyor dryer, the price is relatively cheaper. But the production capacity is small. Moreover, it requires manual loading and unloading.

For conveyor dryer: Continuous tunnel furnace has higher price. And it occupies large area. But tunnel dryer is efficient. Therefore, it is particularly suitable for mass drying operations. The tunnel furnace adds a baking furnace cover on the basis of the conveyor production line. The product enters the conveyor oven from one end trough the oven belt. After drying, it moves out from another end. Therefore, it requires no manual handling. So save time.

(3) infrared conveyor oven vs microwave tunnel dryer

For IR conveyor dryer: Infrared heating uses the principle of electromagnetic radiation heat transfer. It transfers heat in a direct way to achieve the purpose of drying objects. Infrared has a shorter wavelength than microwaves, so its energy is higher than microwaves. IR heating is from the outside to the inside. Firstly ir conveyor oven heat object surface. Then the temperature rises, thereby evaporating water.

In terms of application, infrared tunnel furnaces are more commonly used in industrial fields. Although it can also dry food, it has no sterilization function.

For microwave tunnel dryer: Because the vibration frequency of the microwave and water molecules is close, it is conducive to the formation of resonance. So it allows the food to heat up evenly from the inside. Moreover, microwave conveyor dryer has sterilization function.

6. How to choose right tunnel conveyor oven dryer?

When buying drying equipment, you need to pay attention to various details. Only so we can choose a good conveyor dryer. In addition to clarifying the basic dimensions and parameters of the oven, it needs to confirm the following key points.

(1) Choose conveyor pizza oven

As mentioned above, although the deck oven is cheaper, the pizza made by conveyor oven tastes better. So if you’re pizza shop, it’d better to choose commercial conveyor pizza oven.

① gas or electric conveyor pizza oven?

In fact, the taste is similar. Compared with an electric oven, the cost of a gas pizza oven is lower. The operating cost of an electric pizza oven is directly proportional to the volume. The larger the volume, the greater the power. Then it costs more electricity.

② choose the heating type

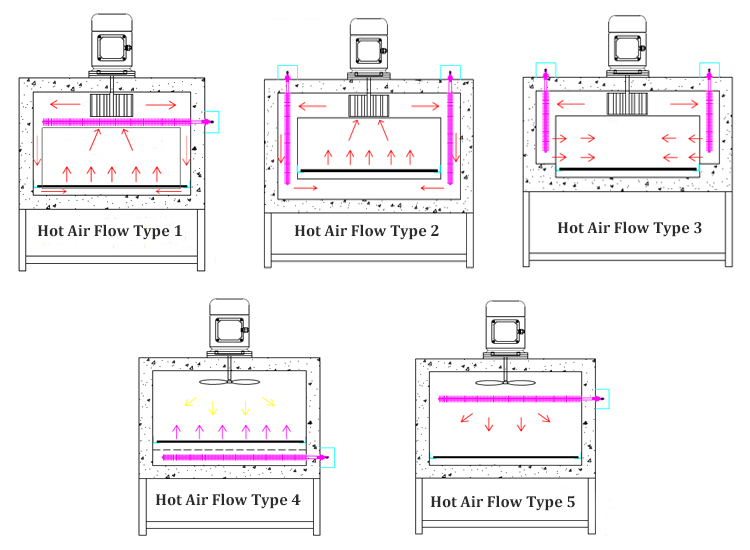

The heating method will affect the taste of the pizza. Some pizza conveyors are similar in appearance. But it uses is vertical heating. The fan is on the side. When opening belt oven, the fan blows out the heat in the oven. As a result, the people outside are too hot. But the temperature of the pizza in the oven does not meet the requirements. Moreover, the heating is uneven. The pizza is not only bad in appearance, but also bad in taste.

So we must communicate well with the manufacturers. Make sure that the pizza oven uses hot air jet technology. Because only with this baking technique, the pizza tastes better.

③ Thermal insulation effect

(2) Choose industrial continuous conveyor tunnel dryer

Tunnel furnaces have a wide range of applications. When purchasing, it is very important to confirm the technical details.

① First of all, inform the product application information

The customer needs to inform the relevant information of the products for drying, such as product size, baking process requirements. Is it necessary to bake moisture or to bake its paint or flux, etc.

Additionally, what is the baking temperature range? Is there a temperature difference requirement? How about the heating time? And how long does it take to reach the drying temperature?

② Secondly, confirm the materials & types of conveyor dryer parts

For inner plate material: when working temperature less than 300℃, it can choose the cheaper galvanized sheet. If it is greater than 300°C, stainless steel should be used. Sometimes in order to prevent material deformation, it is necessary to increase the frame.

For conveyor belt: different applications, different conveyor oven belts to choose. For conveyor dryer screen printing, we usually choose the Teflon mesh belt. Because the temp. is not high in printing industry, the Teflon belt can bear 0~250℃. If tunnel dryer temperature is higher, we need to use stainless steel mesh belt. For example, for conveyor pizza oven, it also uses the stainless steel mesh belt. Of course, all of them use the conveyor belt as a direct conveying carrier.

If you need use the tray as conveying carrier, it can choose the roller conveyor or slat chain conveyor. In addition, if the baking temperature is not higher than 80°C, it can also use PVC or PU belts. In the electronics industry, we usually choose belt conveyor dryer.

③ Thirdly, conveyor dryer heating elements to choose

For industrial conveyor ovens, there are several heaters available. Among them, the transparent quartz tube and black ceramic tube use the infrared heating principle. Quartz heater has very wide applications. But it’s fragile during transportation.

The second is stainless steel heating tube. It is an electric heating element with a metal shell. It is sturdy and durable. However, the heating time is not as fast as other heating tubes.

The third type is the w-shaped heating tube commonly used in tunnel dryers. It uses a metal tube as its outer shell. Electric heating alloy wires are evenly distributed inner the tube. At the same time, metal heat sinks are wound on the surface. So conveyor dryer with this heater has faster heating speed and thermal efficiency.

7. FAQ

Q1: how long does it take to cook a pizza in a conveyor oven?

A1: For example, for American pancake pizza, it usually takes 4 to 5 minutes. The temperature is mostly 230°C.

Q2: how much is a conveyor pizza oven?

A2: Belt ovens with hot air jet technology are more expensive than those without. The former often cost several thousand dollars. But the latter only costs a few hundred dollars.