Choose the Conveyor Shapes:

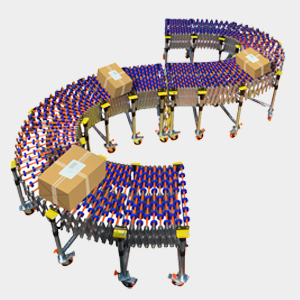

Flat Conveyor / Small Conveyor / Curved Conveyor / Climbing Conveyor / Circular Conveyor / Vertical Elevator Conveyor

Choose the Popular Conveyor Application:

Industry Conveyor / Food Conveyor / Unloading & loading Conveyor / Warehouse Conveyor / Package Conveyor / High Temperature Conveyor

BCC CONVEYOR is a professional manufacturer of belt conveyors and other conveyor machines. Moreover, we can customize most types of conveying equipments and systems. We focus on the production of conveyor equipments and assembly lines. Due to excellent design and manufacturing capabilities, many foreign customers have already bought conveyor machines from our factory. The main conveyor system machines are as follows, such as belt conveyor, roller conveyor, modular conveyor, slat chain conveyors, flexible conveyors, inclined conveyor machine, Z type bucket elevator, etc. In addition to conveyor manufacturing, we can provide customers with overall automation solutions and timely services.

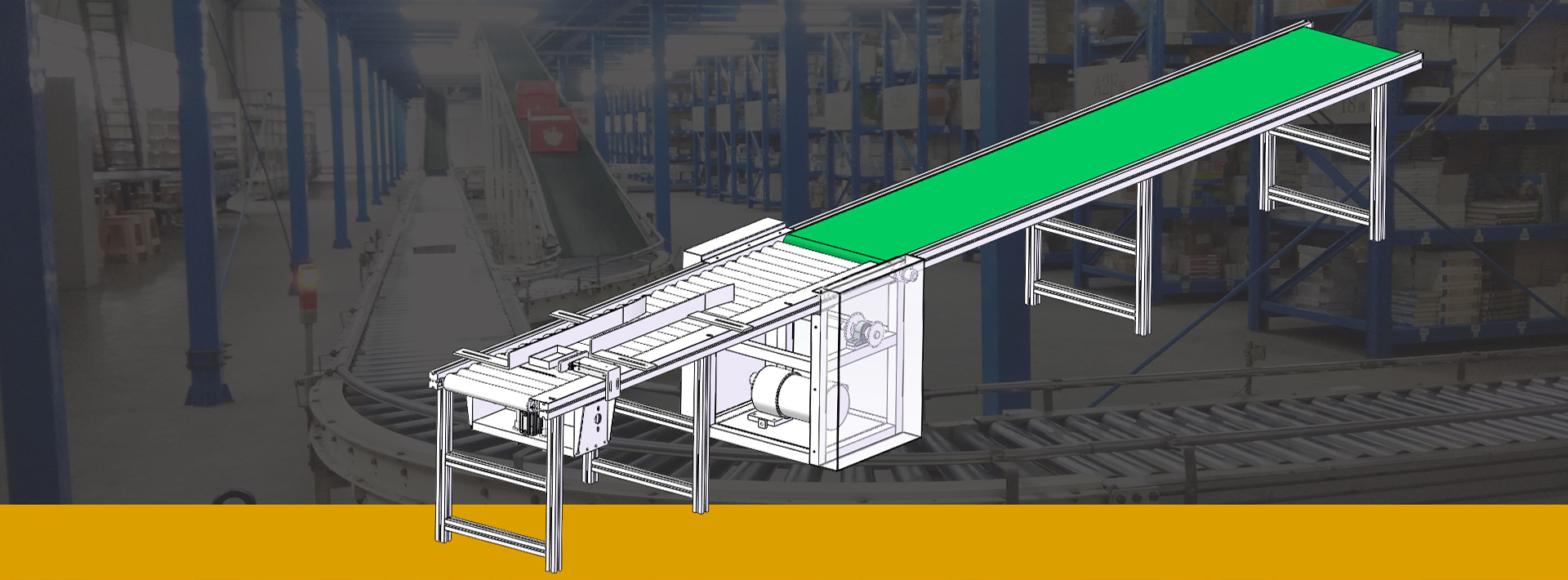

Introduction of Belt Conveyor Machine

What is belt conveyor system? Its working principle is that the motor drives the active roller to drive the belt to move. It uses the continuous or intermittent movement of the conveyor belt to transport various light and heavy items. It can not only convey all kinds of bulk materials, but also convey many kinds of cartons, packaging bags, baggage, parcel and other goods with low weight. Different from roller conveyor, it can transport irregularly shaped objects.

The band conveyor consists of a driving and tensioning device, a belt line body and an electrical control device. 1. The driving and tensioning device include these parts, such as a motor (motor), a gear reducer, a motor sprocket, a drive chain, a driving roller sprocket, a driving roller, a driven roller, a tensioning frame, a power box, and a chain protection cover, etc. 2. The belt line body includes working belt, supporting roller (or supporting plate), edge guard, bracket, foot (or caster), guardrail (optional),etc. 3. In the end, The electrical control device has the following functions: start, stop, emergency stop, frequency conversion speed control, etc.

What’s the feature and benefits of using band conveyor equipment? The band conveyor conveys smoothly. Moreover, there is no relative movement between the material and the transportation belt. So it can avoid the damage to the conveyed material. Compared to other conveyor machines, it has low noise and is suitable for occasions where the working environment is relatively quiet. In addition, the belt conveyor is simple in structure and easy to maintain.

What’s belt conveying machine used for?

Belt conveyor is the most widely used conveyor equipment. Firstly, the rubber belt conveyor machine is mainly used to transport coal, ore, grain, etc. Among them, we often use PVC belt conveyors for various industrial industries, such as automation equipment, electronics industry, medical industry, injection molding industry, logistics express industry, etc. And it can use the PU belt conveying machine for food industry. It is widely applied for food industry, such as candy, bread and cake baking, meat processing and seafood products, etc. Of course, the safety of PU belts is very important for food applications. And our PU conveyor belt has passed SGS certificates.

In addition, you can add workbenches on both sides of the belt conveyor (assembly line conveyor). So it can act as an assembly line for electronic instrument assembly, home appliances assembly, food packaging, etc. Moreover, the inclined belt conveyors are widely used for truck unloading and loading. And the climbling cleated conveyor belt machine is the popular material handling equipment for many kinds of bulk material, such as grain, rice, flour, seeds, coffee beans, plastic parts, bottle cap, etc.

How to choose a right belt conveyor?

In order to help you choose the right belt conveyoring machine, please inform the detailed information, such as 1) your application? 2) weight of your product? 3) the length, width and height of conveyor machine you need? 4) what’s the frame material you need? 5) dose need to add other functions to conveyor machine or not?

Why need to know the application? Because different application, choose different belt materials. And there are several kinds of conveyor belts, such as PVC belt, PU belt, rubber belt, timing belt, nylon belt, canvas belt, pvk belt, teflon belt, etc.

PVC conveyor belt: The material is polyvinyl chloride (PVC). It composes of polyester fiber cloth and polyvinyl chloride glue. We can use it in many industries. Because PVC belts are easy to process, the price is more advantageous. PU conveyor belt: the material is PU material, namely polyurethane. It can directly contact food, so the food industry generally uses PU conveyor belts. The main color is white and blue. Compared to PVC belts, PU belts are more expensive. The Teflon conveyor belt can adapt to the high temperature of 250℃. It is often used in conveyor drying oven for all kinds of printing and food. PVK conveyor belts are often black and the main application is for the logistics industry.

Why need to know the weight of your product? Different weight, choose different power motors. Moreover, it will choose conveyor belts of different thicknesses.

What frame materials to choose? Available frame materials of belt conveyor machine are usually aluminum extrusion profile, carbon stell square tube, stainless steel (SS201, SS304 and SS316). If for food industry, it is best to choose the SS304 stainless steel material.

What functions can be added to the belt conveyor equipment? The conveyor height and speed can be adjustable. If add a speed regulator or frequency converter, it can adjust the speed of the belt conveyor. Moreover, it can also add photoelectric sensor, timer, counter, etc.