Description

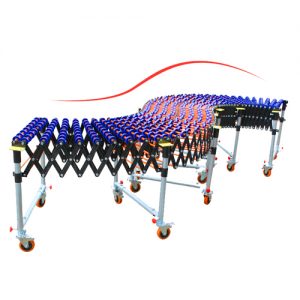

Flexible roller conveyor is also namely expandable roller conveyor. We usually use the flexible gravity roller conveyor system in warehouse logistics and material handling industries. What is flexible conveyor? As the name suggests, you can expand it freely. So it can reach the length required by the customer. At the same time, you can fold and push the expandable portable conveyor to the designated storage position. Telescopic roller conveyors are often used with fixed powered conveyors. Thus, it can provide a quick additional function of expanding or turning conveying.

Where is the flexible conveyor roller used? In short, flex roller conveyor is mainly applicable for conveying and sorting various items. Especially we usually use it for truck loading / unloading. Expandable conveyor can be suitable for conveying all kinds of items on the flat bottom, such as carton, box, pallet, etc. Conversely, if you transport items with a soft bottom surface, they are likely to get stuck during transportation. In addition, the single weight of the goods should not be too heavy. It is best not to exceed 100KG.

How does expandable conveyor work? Firstly, after the power is on, the motor runs to output power. Then, the power is delivered to the roller assembly through O-belt wheels or chains. Immediately afterwards, the roller assembly runs. Finally, the interaction force between the roller and the conveyed goods guides and pushes the movement of the goods. The flex roller conveyor completes the entire conveying action.

The Specification of Expandable Roller Conveyor

Conveyor type: single-roller or double-rollers flex conveyor;

Drive type: “no power” or “powered” are both available;

Stretching ratio: 1: 3 (so if the expanded length is 9 meters, then you can shorten it to 3 meters);

Conveyor width: 500mm, 600mm, 800mm, 1000mm, 2000mm, etc;

Conveyor height: 450mm~1500mm (adjustable & customizable);

Loading-bearing: 20KG~150KG/meter (customizable);

Roller material: galvanized roller, SS201 / SS304 stainless steel roller, PVC roller, etc;

Roller diameter: φ38mm, φ50mm, φ76mm, etc;

Support legs material: round or square tube~alloy, carbon steel, stainless steel (customizable);

Expandable connection plate: 2.5mm thickness alloy, carbon steel, stainless steel (customizable) (Galvanizing or electrophoresis treatment);

Trammision part: round PU O-shaped belt or V-ribbed belt;

Movement direction: both two directions are available;

The Structure & Features of Flexible Roller Conveyor

(400-flex roller conveyor, 401-expansion plate, 402-frame, 403-moving shaft, 404-roller, 405-double groove transition wheel, 406-transmission belt, 407-moving caster, 408-power output device, 409- main power wheel, 410-handle)

It can achieve the expansion and contraction of the entire length manually by pushing the handle (410). The handle is at the end of the expandable roller conveyor. There is a control box below the handle. The control cable is hung under each expansion plate. In addition, the movable casters (407) are with brakes. Therefore, when in the braking state, manually pushing the handle will not cause the whole expandable conveyor to move. When you need to move the position, it only need to release the brake device of the casters.

The multiple sets of expansion plates (401) adopt the same design. Thus, this ensures that the distance between the intersection and the vertex of the stretch piece (401) is constant when it stretches. So it allows the flexible roller conveyor to expand or turn without affecting the power transmission of the motor. Firstly, the motor power is transmitted to the pulley (409). Then pass the double groove transition wheel (405) to the roller (404).

Features of Expandable Conveyor

The conveying distance of the general conveyor is fixed. And it is not easy to realize continuous automatic transportation. So under normal circumstances, it can only be straight line transportation. In other words, you can’t turn. In addition, it is not possible to freely switch between straight and curved conveying. On the contrary, the expandable roller conveyor is portable. Moreover, it can freely switch the turning angle. Thus, the application is very flexible.

Its characteristics and advantages are as follows:

1. Firstly, the cross-mounted expansion plates (401) base on the frame. Then, install the double-groove transition wheel at the intersection of the telescopic plate (402). At the same time, a transmission belt (406) is on the transition wheel. A roller (404) and a movable shaft (403) are respectively installed at the upper and lower vertices of each expansion plate.

2. The motor (408) of the flexible roller conveyor is in the middle. Firstly, its power is transmitted to the double groove transition wheel (405) through the pulley (409). Then it passes from the transition wheel (405) to the roller (404). Pass through the drive belt (406).

3. The axial center point of the pulley (409) is coincident with the vertex below the telescopic plate (401).

4. Two expansion sheets form an X-shape. So it can stretches and contracts through the central turning point. 7 groups or 8 groups of X type form a group. The expansion ratio is about 1:2.5~1:3. For instance, if the length of the flexible roller gravity conveyor is 10 meters, the contracted length is 2.5 meters to 3.3 meters. Therefore, when completing conveying, it can folde expandable conveyor up. No need to take up space. The thickness of the stretch sheet is 2mm. Moreover, it uses electrophoresis surface treatment. So the flex conveyor is sturdy and durable.

5. It can move the telescopic roller conveyor to various positions through the supporting parts. Besides the height is available by lifting. In addition, all casters are 125mm full-brake universal wheels. So the collapsible conveyor is safe and reliable.

6. The handle is convenient for pushing, pulling and moving the expandable conveyor. It can also act as a blocking device. So it can prevent the cargo from falling on the end face.

Other features:

7. Most of the powered flexible conveyors are driven by V-belt or O-belt. The V-ribbed belt model has the characteristic of large starting torque. It is suitable for linear applications where larger loads require higher speeds. On the other hand, the O-belt model is suitable for some scenes that need to be used in corners. Both models are capable of variable speed control and forward and reverse control.

8. Most importantly, it can reduce manual handling and reduce labor costs. Because you can move the extendable conveyor to any place to convey goods. In addition, since it can be adjusted to a suitable height, there is no need to bend over frequently. Therefore, flexible roller conveyor is more ergonomic. So it can reduce labor intensity.

9. You can connect several expandable roller conveyors together by the joint hooks. And if it’s powered flexible roller conveyor, you can also connect the cable lines. So it will form a long conveyor line.

10. In addition, it can add the side guards. Then it will protect the goods from falling. Further, the expandable roller conveyor is very convenient to install and maintain.

How to customize the telescopic roller conveyor?

Before you decide to customize the expandable gravity roller conveyor, you need to know choose “skate wheel conveyor” or “flexible roller conveyor”. Moreover, you need the “no power” or powered flex conveyor.

Skate wheel vs roller conveyor: Firstly, both of them have specific advantages of expandable conveyors. They are only suitable for flat-bottomed goods. And the load-bearing capacity not as good as other conveyors. But they have also some differences. Usually wheel conveyor can bear 80KG. However, the flex roller conveyor can bear 150KG. On the other hand, the powered flexible conveyor refer to roller conveyor.

1.Tell us your application (what objects to convey);

2.The weight and size of the conveyed objects;

3.What’s the “open length” you need? (the price depends on the “open length”)

4.You need “with motor” or “without motor”?

5.If you need the side guards, just tell us.

6.If you need the double-roller flexible conveyor, just tell us.

Reviews

There are no reviews yet.