Showing all 5 results

Assembly conveyor is a kind of production line conveyor systems. Assembly line conveyor system integrates a variety of functions, such as conveying, positioning, stopping, lifting, rotating, turning, control, etc. Therefore, it’s ideal automatic production equipment. It has wide applications for industrial products assembly, such as electronic, car seat, home appliances, lithium battery, semiconductor, metal parts, molds, workpieces, etc.

As assembly conveyor manufacturer, we can customize three kinds of conveyor production lines. That is to say, workpiece pallet conveyor system, free flow chain conveyor and production line conveyor belt. Among them, the first two are automated assembly lines. And the last one is a manual assembly line. In addition, there consists of transverse, longitudinal and u shaped production lines according to the shape.

-

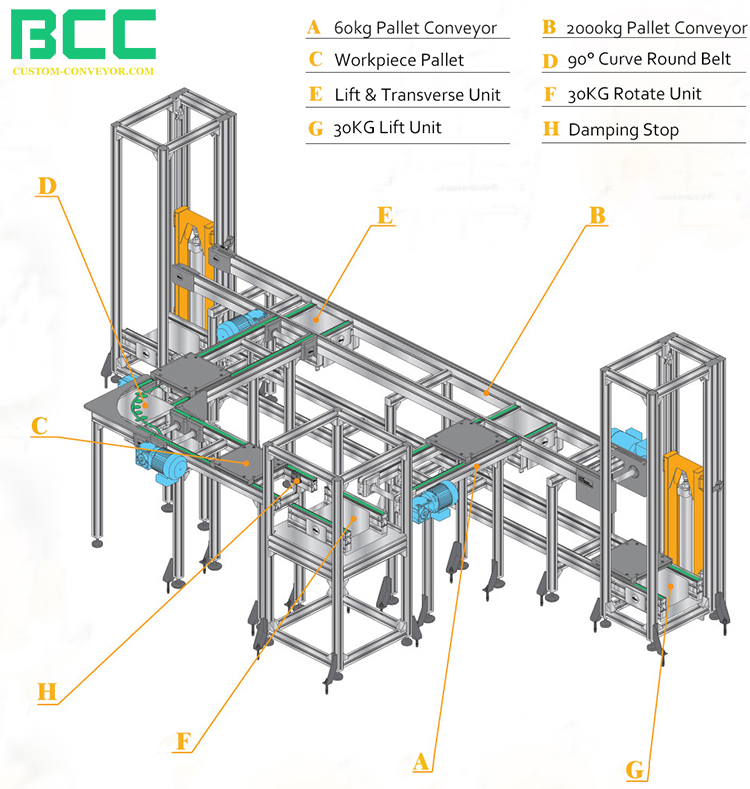

1. Modular Workpiece Pallet Assembly Conveyor System

-

(1) What is modular workpiece pallet conveyor?

- In fact, it is a kind of modular assembly line. Our workpiece conveyor is similar to bosch TS pallet conveyor. It includes transverse conveyor and longitudinal conveyor. Moreover, there are many types for payloads to different weights, from a few kilograms to 2000KG.

Modular workpiece pallet assembly conveyor system is a kind of tooling plate transfer platform. It’s suitable for material handling, product assembly and test, etc. So it can meet the requirements of various industrial automation production.

The application of workpiece pallet assembly conveyor

- electromechanical industry production lines,

electronics assembly lines,

computer monitor production lines,

computer mainframe production lines,

notebook computer assembly lines,

air conditioning production lines,

TV assembly lines,

microwave oven assembly lines, - printer assembly lines,

audio amplifier production lines,

engine assembly lines,

screw machine assembly line,

dispenser assembly line,

soldering machine assembly line,

mold assembly line,

car seat assembly line,

metal parts assembly line.

(2) Technical Parameters of Pallet Transfer Conveyor System

|

Conveyor |

Conveyor Medium |

Conveyor Length |

Pallet Size |

Max |

Max. Conveyor Speed |

|

PTS1 |

Toothed Belt |

400≤L≤6000 |

160≤Bwt≤400 |

60 |

20 |

|

PTS1/H |

Nylon Belt |

1200≤L≤12000 |

160≤Bwt≤640 |

160 |

20 |

|

PTS2 |

Accumulating Roller Chain |

600≤L≤ 12000 |

160≤Bwt≤800 |

1000 |

20 |

|

PTS4 |

Accumulating Roller Chain |

1000≤L≤ 18000 |

400≤Bwt≤1200 |

2500 |

20 |

|

PTS5 |

Roller |

1000≤ L≤ 6000 |

300≤Bwt≤1200 |

4500 |

15 |

(3) The Types of Workpiece Pallet Conveyor

Pallet conveyor systems are suitable to a wide number of industrial production processes. We can use it to establish automatic workpiece flow solutions in machining, assembly, and test processes. Besides standard conveyor modules make it quick and easy to create simple as well as advanced layouts for routing, balancing, buffering and positioning of pallets.

Workpiece pallet conveyor differs in size and load capacity. The pallet transfer system consists of standardized components. Therefore, it can combine different units to meet specific automation requirements. We usually customize 4 types of workpiece pallet-based conveyor systems. That is to say, timing (toothed) belt conveyor, nylon belt conveyor, accumulating roller chain conveyor and roller workpiece conveyor.

-

1) Timing Belt Conveyor for Max Payloads to 60KG

- This modular assembly line conveyor uses the toothed timing belt. So its load-bearing capacity is not high. Please note the 60KG is its total load-bearing capcity, not the load for single workpiece pallet. And the load-bearing capcity of single workpiece pallet is 15KG.

Technical Parameters of modular workpeice pallet assembly timing belt conveyor

Workpiece conveyor length: 220~6000mm;

Load capacity of assembly conveyor system: 0~60KG;

Conveying speed: 5~20m/min;

Workpiece pallet size: 160, 240, 320, 400, 480 and 640mm;

Stands spacing distance: 800~1600mm;

Conveying medium is the antistatic toothed belt;

Motor installation type: end drive or center drive.

The Features of Timing Belt Pallet Assembly Conveyor

① It’s suitable for conveying in light load occasions;

② Due to the modular design, it is easy to install and maintain;

③ Because of using aluminum alloy frame, it’s convenient to install other accessories, such as sensors, buffers, etc.

④ It is easy to realize the accumulation function. Because it cooperates with hoisting machine, round belt turning machine, hoisting traverse machine and other components, it can realize automatic circulation conveying.

⑤ This conveyor assembly line is flexible, clean, stable, low noise, long life.

2) Modular Nylon Belt Assembly Pallet Conveyor for Max Payloads to 160KG

This kind of nylon base belt conveyor has higher load capacity than the first one. Its max load-bearing is 160KG.

Technical Paramters of This Assembly Conveyor System:

Max load capacity of workpiece pallet assembly conveyor: 160KG;

Length of this assembly line conveyor: 600~12000mm;

The size of workpiece pallet: 160mm~640mm;

The conveyor speed: 5~20m/min;

Conveying medium: nylon base belt;

Drive type: direct drive, and motor can be at end or center;

kind note:

① The load is the total load of the assembly line conveyor. The unit load capacity is ≤0.6kg/cm.

② The default flat belt is an anti-static base belt with a width of 30mm.

Characteristics of Nylon Belt Pallet-based Conveyor System

① Modular design allows quick assembly. At the same time, it is convenient for subsequent maintenance.

② Suitable for long-distance transportation of small loads.

③ Convenient to realize the accumulation function. Moreover, with other components, such as lifting & positioning, it can achieve ultra-high flexibility design.

④ The assembly line conveyor needs to be used with our pallets. If not use our pallets, you need to confirm with our company before you can use it.

⑤ The assembly conveyor system needs to transport objects according to the conveying direction. Reverse conveying is prohibited.

⑥ The conveyor frame uses aluminum profiles. Therefore, it can quickly connect with external devices. So that you can install conveyor production line quickly.

⑦ It is strictly forbidden that metal or sharp objects on the pallet directly contact and rub the belt. Otherwise, the conveyor belt will wear out or break quickly.

3) Modular Accumulating Roller Chain Conveyor~Three Types of Payloads to 200KG, 500KG & 2000KG

Compared with the above conveyor assembly lines, this conveyor system has much higher load capacity. Moreover, this conveyor product line uses the accumulating roller chain as the conveying medium. At present, we design three types pallet chain conveyors to adapt to different load requirements.

Technical Specifications of Accumulating Roller Chain Assembly Line Conveyor

Conveyor load capacity: three types~200KG, 500KG and 2000KG;

Modular assembly line length: Max 2000mm for 200KG load, and Max 10000mm for 500KG & 2000KG load;

Workpiece pallet conveyor speed: Max 20m/min;

Workpiece pallet size: 160~640mm;

Conveying medium: accumulating roller chain (the roller material can be nylon and steel).

kind note:

① For 200KG & 500KG load assembly line conveyor, the unit load capacity is ≤1.2kg/cm;

For 2000KG load modular pallet conveyor, the unit load capacity is ≤2.0kg/cm.

② The chain uses the durable stainless steel chain.

Features of Pallet Chain Assembly Line Conveyor

① Applicable for goods transfer of medium & high load, such as engine, car parts, mold, etc;

② This pallet transfer conveyor uses aluminum profile and stainless steel chain. So the structure is stable. Besides, it’s convenient to install.

③ The assembly line conveyor design can be very flexible. For example, if you want to achieve turning fuction, it can add the curve conveyor quickly. So it can become a circular assembly conveyor system.

④ Because of using accumulating roller chain, the pallet transfer system is low noise and economical.

⑤ Compared with normal conveyor machine, it can’t convey workpieces in both directions. The workpiece pallet can only move towards to motor.

(4) Modular Pallet Assembly Line Conveyor Layout

Why need modular pallet assembly line conveyor? The biggest reason is that its design and layout are very flexible. For example, we only need to add the corresponding components to achieve various functions such as changing the conveying direction, pausing, and rotating. In order to understand the layout of the conveyor, we need to understand the relevant functional components firstly.

-

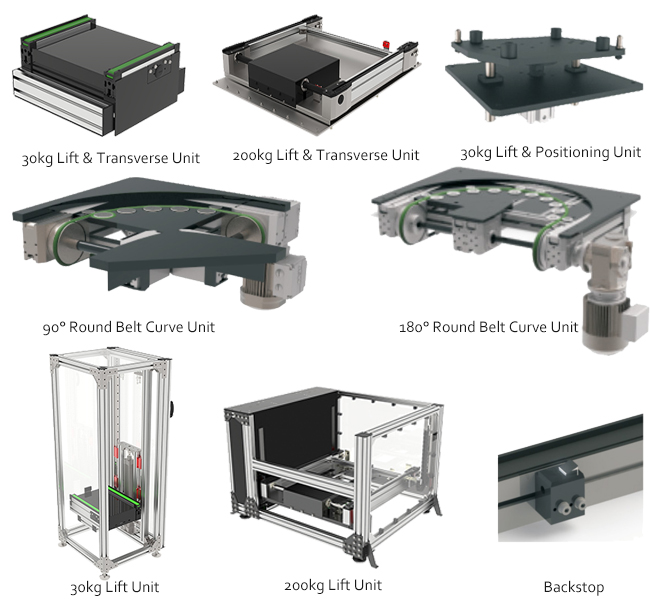

1) Components of Pallet Transfer System

① 30kg Lift & Transverse Unit Fuctions:

Firstly, it can realize the lateral movement of the circular assembly line conveyor at the corner. At the same time, it can also realize the lateral movement of the branch line.

When the it needs to lift and move the workpiece pallets laterally, stop and perform the lifting and horizontal movement. If the tray does not need to be diverted, the device keeps the original low position so that the tray can pass directly.

Finally, itt can realize the function of diverting and confluence.

② 200kg Lift & Transverse Unit Features & Functions:

In fact, it has similar functions to the above 30kg unit. Modular design, strong practicability.

It can change the conveying direction of the pallet. For example, this device can move the pallet laterally to another assembly line conveyor.

Finally, it uses high-strength aluminum profile frame. So it is convenient to install this unit onto the assembly conveyor system. Besides, it is also easy to install other accessories.

③ 30kg Lift & Positioning Unit Feature & Functions:

The component realizes the positioning function through the positioning pin and the pallet pin together;

The initial positioning height bases on the selection to adapt to the change of assembly conveyor type;

It is suitable for all our modular pallet conveyors and supporting pallets.

④ 90° Curve Round Belt Unit Feature & Functions:

Firstly, it can achieve a 90° turn of the workpiece pallet. And it will not change the conveying direction of the pallet. So it can help to achieve a circular assembly line conveyor.

Secondly, this curve module pallet conveyor is separately equipped with a motor;

Thirdly, the aspect ratio of the conveying pallet cannot exceed 1.5.

Finally, this turning mechanism can only pass a single pallet at a time. And stacking of pallets is prohibited.

⑤ 180° Curve Round Belt Unit Feature & Functions:

Above all ,this pallet transfer module can make pallet turning at 180°.

In addition, other features are same to the above 90° curve unit.

⑥ 30kg Lift Unit Feature & Functions:

This lifter uses the air cylinder to achieve lifting function. So it can realize vertical circulation between high and low assembly line conveyors.

And the conveying medium is toothed belt. Thus, this lifter is suitable for light-load occasions.

The elevator is with a check valve. So it can prevent the pallet from falling suddenly when the air is cut off. Thus, it ensure the safety of assembly conveyor system.

⑦ 200kg Lift Unit Features & Functions:

First of all, this lifter is suitable for conveying occasions where the full load of a single pallet is within 200KG.

Secondly, different from the above 30kg lifter, the conveying medium is standard chain or 08BS accumulating roller chain.

Because it is an independent component of modular design, it is convenient to install into an assembly line conveyor system.

Similarly, it can also realize the vertical circulation of workpiece pallets.

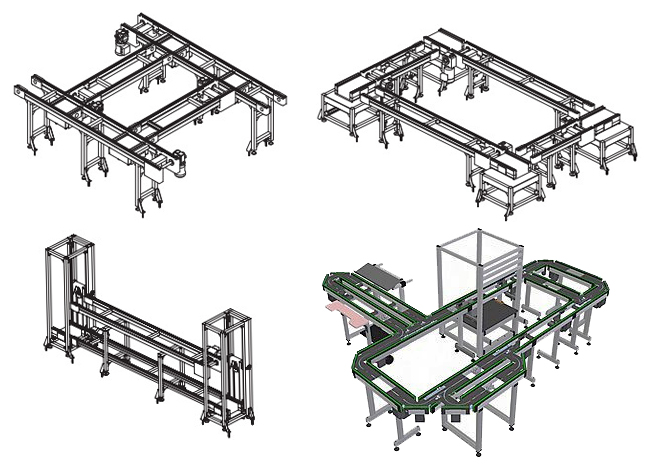

2) Assembly Conveyor System Layout

Because there are multiple functional components, it is possible to install the assembly conveyor system of various shapes and layouts. Moreover, these components are modular in design. So the assembly line conveyor layout can be very flexible and diverse.

For example, because of the lift-transverse unit and curve device, it can easily build a horizontal circulation assembly production line. Additionally, it can use the lifter to quickly build a vertical conveying system. They are the two most common assembly conveyor layouts. Of course, it can also assemble more complex production line conveyor systems as requirements.

Transverse conveyor and longitudinal conveyor are used to match fully automatic processes. They use a special tooling board to match the application. Its positioning accuracy is high. Many automated production processes are using modular assembly line conveyors. For example, dispensing, curing, automatic screw locking, riveting, stamping, welding, etc.

(5) How to install the modular pallet assembly line conveyor?

Since they are all modular designs, they are very convenient to install. You can easily complete the operation according to the assembly conveyor installation instructions. If you receive the conveyor machine in parts or units, please follow the below assembly instructions.

In addition, due to the similar structure of several modular pallet conveyors, here we mainly explain the installation of chain assembly line conveyors.

Step 1, assemble the frame of modular pallet conveyor.

Assemble the conveyor stands and put them to the layout position. And then mount the guide rails onto the support legs. Finally, it needs to adjust the foot to ensure same height of stands.

Step 2, install the drive unit and driven unit

It is similar to plastic chain conveyor. This modular pallet chain assembly line conveyor also include drive unit and driven unit. Install them onto the guide rails. Of course, the motor installation position can be at end or in the middle as needs.

Step 3, assemble the accumulating roller chain

This installation step is relatively more complicated. Next, I will explain how to install the accumulating roller chain on the conveyor assembly line.

① Firstly, put the conveyor chain on the chain shaft. It can avoid chain damage from twisting during the chain installation process.

② Secondly, guide one end of chain with a fine steel wire. Let the chain go along the lower part of drive unit. And then go trough lower part of assembly conveyor. Immediately afterwards, bypass the driven sprocket of the driven unit. Finally connect the ends of the chain with chain slipknot.

③ Similar to small conveyor belt, it needs to adjust the chain tension after installation. Otherwise it will affect the load capacity of the assembly line conveyor. At the same time, it also affect normal operation.

Step 4, install other components or accessories

Put the workpiece pallets onto the assembly conveyor system. In addition, our modular assembly line usually have other accesories, such as damper and return stop. It usually mount them onto the guide rails with screws.

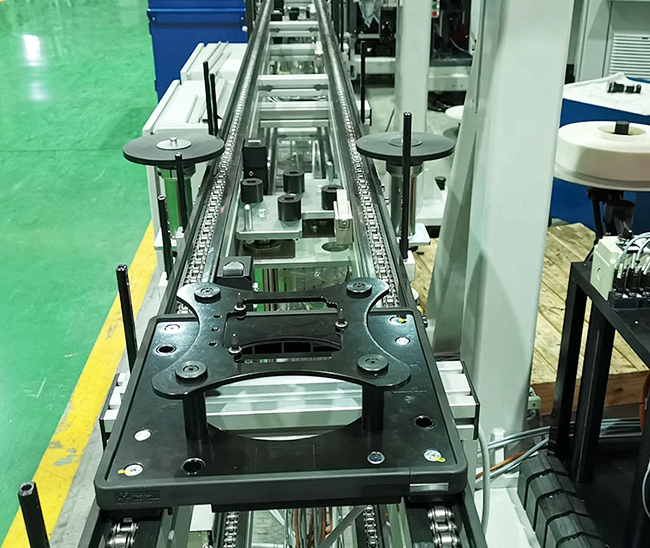

2. Free Flow Conveyor Assembly Line

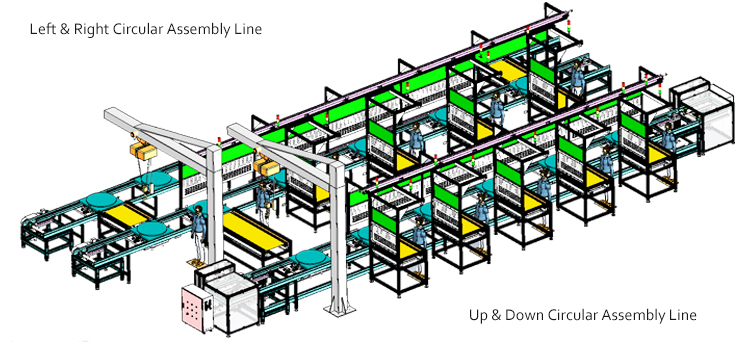

Free flow chain conveyor is also a common automated assembly production line. In fact, this conveyor is very similar to the above accumulating roller chain conveyor. Both of them use the accumulating roller chain as the conveying medium. Besides, there are also two types: horizontal and vertical circular assembly line. There are also the components, such as lift & transverse unit and blocker.

But there are also some differences. Firstly, free flow chain conveyor has more complicated structure. It’s often equipped with ESD workbenches and light stands. Besides, the structure of lift & transverse unit and blocker is a bit different. In addition, the length of free flow chain conveyor can be longer. It can reach 30m.

What is free flow chain conveyor?

It is also namely accumulating roller conveyor or double-speed chain conveyor. As the name implies, the conveying speed of the tooling plate is greater than the transmission speed of the chain. Besides it’s twice or three times the transmission speed.

Therefore, the tooling plate supporting the workpieces on the chain can move quickly. In addition, the blocker can stop the tooling board at the corresponding operating position. The tooling plate can rotate. And it can achieve accumulation by corresponding instructions. Because of its high-efficiency conveying effect, it becomes very popular.

Characteristics of free flow conveyor assembly line

1) The conveyor uses roller chains as the transfer medium. The roller is in direct contact with the track. Moreover, the rotation of the roller forms the transmission of the product on the roller. So it can achieve accumulating functin.

2) Aluminum profile acts as guide rails. So it make the entire assembly conveyor system have high stability and durability. Moreover, it can carry a heavy load. At the same time, it can achieve long conveying distance.

3) Beautiful structure, low noise, diversified functions and high degree of automation.

Structure & Technical Specification of Free Flow Chain Conveyor

The form below is an example of a 30-meter assembly line conveyor made for a customer.

|

No. |

Parts Name |

Technical Specification |

|

1 |

Drive System |

① Taiwan Brand 3HP Horizontal motor; ② Speed of workpiece pallet: 6m/min; ③ The transportation of tooling board uses RF2060, 3 times speed chain.. |

|

2 |

Frame Structure |

① The bracket adopts 50mm*50mm*2.0mm square tube. The height of the working surface: 740±20. The workbench surface is pasted with anti-static rubber. ② The guide rails on both sides of the assembly line conveyor use 100*118mm aluminum profile. ③ The lighting uses T5 18W single LED lamp with cover. In addition, the light support frame uses 20*40 iron tube; |

|

3 |

Control System |

① Controlled by Mitsubishi PLC; ② Mitsubishi Air Switch; ③ OMRON relay. |

|

4 |

Tooling Plate |

① Size (mm): (850)L*(850)W*(20)T; ② The tooling board uses 20mm splint plate. The double-layer round structure, and rotates freely for transition. The surface is pasted with green anti-static rubber. |

|

5 |

Blocker |

QX-3 high-quality blocker with foot switch control |

|

6 |

Lift & Transverse Unit |

① Taiwan brand 60W motor, driving timing belt conveyor; ② Cylinder with two-position five-way solenoid valve for lifting; ③ The control adopts OMRON travel switch. |

|

7 |

Workbench |

① Size: 600*400*750mm; ② The independent workbench stands use 30*30mm square tubes. The worktop is made of 18mm wood plate. Besides,the surface is pasted with green anti-static rubber. |

3. Manual Assembly Line Belt Conveyor

Sometimes, we don’t necessarily need a fully automated assembly conveyor. So it can choose the manufal assembly line. The most common is the assembly line table. In fact, it also contains several types according to needs and structures. Of course, it mainly composes of belt conveyor and ESD workbench.

What is manual assembly line?

It is also called assembly line workbench. It is an equipment that can improve work efficiency. At the same time, these work needs a lot of manpower. According to the operating speed of the personnel, it can adjust product conveying speed. And it can realize continuous assembly production.

It usually also uses aluminum profile as the frame. At the same time there is a belt conveyor in the middle. There are anti-static workbenches on both sides to facilitate workers to assemble products.

Features of Manual Assembly Line Belt Conveyor

① It adopts assembly line operation, so it can greatly improve production efficiency;

② Use standard materials and accessories to assemble. Thus the structure is simple and the application is flexible.

③ Simple modification. You can expand the structure function at any time as needed. Especially sometimes it can add the frame structural parts at will without disassembly.

④ Finally the materials can be reused. You can reuse aluminum profiles and other accessories. So save production costs. This assembly line conveyor is environmentally friendly.

4. How to choose the right assembly line conveyor system?

Industry is now developing rapidly. Therefore, all industries have higher and higher requirements for production efficiency. Whether you produce electronic products or car seats, it needs assembly line. So what is the best assembly conveyor system? In fact, this is not only a technical issue, but also an economic issue.

(1) Automated vs manual ?

Different countries, different situations. In developing countries, labor costs are relatively low. The initial investment of automatic production lines is generally very large. So many enterprises usually choose the manual assembly line. The investment in the manual assembly line is much smaller. Companies can often recover costs quickly.

For example, it has wide application in the home appliance and electronic industries. At the beginning of the 21st century, these industries were very common in China. Because labor costs were low at that time. So this kind of assembly production line is often used. But so far, many of these industries have moved to India and Southeast Asian countries.

On the other hand, in developed countries, companies often choose automated assembly lines. The labor costs in these countries are high. Of course, because many industries in these countries are high value-added, they can withstand the high investment costs of automation equipments.

Therefore, each company should consider whether to choose an automatic or a manual assembly line based on the return on investment of your own products. In addition, we must also consider whether there are corresponding technical personnel to operate and maintain equipments.

Although the modular assembly conveyor has a simple structure, it is always more complicated than a manual assembly line. Therefore, it needs special technical personnel for operation and maintenance. The maintenance cost is relatively high.

(2) How to choose modular assembly line?

There are many factors that affect the choice of modular pallet conveyor assembly.

① What product to assemble?

Firstly, you need to inform the conveyor manufacturer of product information, such as product type, weight and size. Some products have special requirements for conveyor materials. For example, medical equipment or pharmaceutical packaging has high requirements for sanitary conditions. At this time, we need to choose a special conveying medium, such as modular mattop chain.

Moreover, different product weights, different assembly line conveyors to choose. As mentioned above, the timing belt conveyor is suitable for light-load products. The accumulating roller chain conveyor can transport heavy-duty products. In additon, different product sizes, different conveyor width to need. Besides, it will choose different workpiece pallets. Additionally, products with too large sizes are not suitable for vertical circulation assembly lines.

② Determine the information of assembly conveyor system

Above all, it needs to inform the conveyor shape & layout. Determine if the modular assembly line is straight, circular (horizontal or vertical), or other shapes. How about the conveying route? Where does it need to turn? These need to be confirmed based on the factory area and production process. In addition, sometimes in order to save floor space, we will choose a vertical circulation assembly line.

Of course, you need to tell the conveyor length. Some single assembly lines cannot be made too long. If the length of your assembly line conveyor exceed 15m, you’d better to choose free flow chain conveyor.

Finally, it needs to know the conveyor speed. Do you need the workpiece pallet to move slowly or fast? This needs to be determined according to your production capacity requirements and process. The conveying speed of some products cannot be too fast.

③ What functions need to implement?

Different functions, different components or accessories to need. For example, how about the positioning accuracy? Where do products need to stop, rotate, and turn? Whether need to install an emergency stop button? And do you need to install fixtures on the conveying medium? If you want to implement the counting function, then it needs to install the sensor.

If you customize the free chain conveyor, you’d better to confirm whether need the accesories, such as ESD workbench and lights.

④ The Plant Environment

That’s right. The plant environment will also affect the choice of assembly line conveyor. For example, if the plant has explosion-proof requirements, so the selection of the motor is also very important. At the same time, whether the workshop temperature is extremely high or extremely low? In addition, other factors, such as cleanliness, air humidity, and dryness will also affect the selection.

(3) How to choose the manual assembly line?

The choice method and step are similar to modular pallet assembly conveyor.

① Choose the type

There are many types of manual assembly lines. So you need to know what type you need. You can refer to the picture above. Whether it needs the ESD workbench and lights? Double-side or single-side? Straight or circular assembly line conveyor?

② Inform the product information

Different products, different materials to choose. For example, the manual assembly line is popular in electronic industry. We know many electronic products have requirement for anti-static. So we need use the ESD conveyor belt and workbench. Moreover, different weights, different motor to use.

③ Determine the conveyor sizes and details

How long do you need? And how about the height? The regular height is 750mm. And do you have requirements for the frame material and motor brand? Usually, the frame material is aluminum profile and painted steel tube. Additionally, whether you need other accessories, such as exhaust pipe and electric fan?

In short, to choose a suitable assembly line conveyor system, you need to consider the situation of your own enterprise carefully. At the same time, we must do a good job of technical communication with the manufacturer.