Description

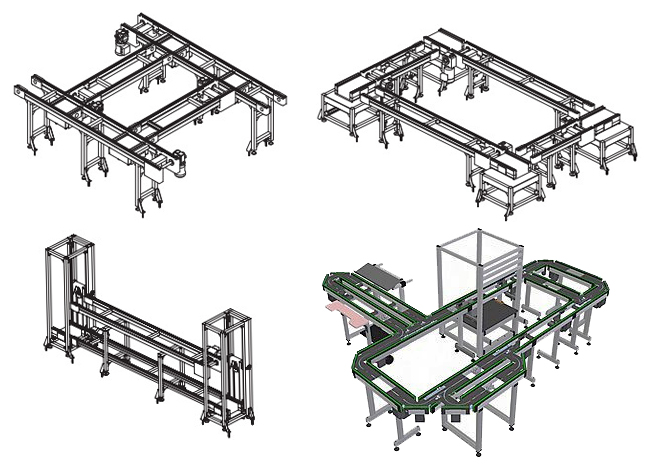

This pallet assembly line belt conveyor adopts timing belts for silent conveying. It is a kind of modular assembly line conveyor systems. Firstly, it uses the workpiece pallet as a carrier for conveying products. Then, the pallet moves on the toothed timing belts. In fact, this modular assembly line is like bosch TS pallet conveyor. Due to its modular design, the layout is flexible. At the same time, many companies use it to assemble and test products.

As assembly line conveyor manufacturer, we can customize several conveyor production lines. For example, we can manufacture the timing belt assembly conveyor for light-load occasions. Different from free flow conveyor, its max load capacity is 60KG. So this kind of workpiece conveyor has wide application for electronics and automotive parts.

It can realize the conversion between station and station. At the same time, it can realize the reflow of the upper and lower layers of the workpiece pallets. Timing belt conveyors can add other components to form a more complex assembly line conveyor system. For example, it can add a light-load lifter to form a vertical circulation assembly line. In addition, it can also add stop mechanisms and sensors to stop and release the product.

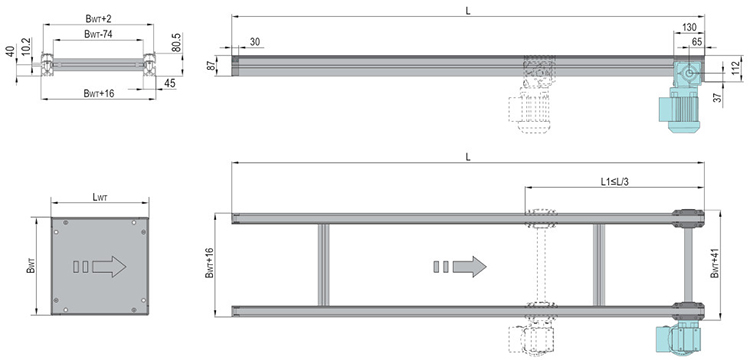

Technical Parameters of Modular Assembly Line Belt Conveyor

|

Modular assembly conveyor length |

220~6000mm |

|

Tooling board size |

160~640mm |

|

Pallet assembly conveyor height |

Custom as needs |

|

Max load capacity (total) |

60KG |

|

Conveying speed (max load) |

5~20m/min |

|

Conveyor medium |

Toothed timing belt |

|

Frame material |

Aluminum profile |

|

Motor installation type |

End drive or center drive |

Characteristics & Advantages of Assembly Line Conveyor System

1. First of all, this pallet assembly conveyor is suitable for light load occasions.

2. Secondly, you can add turning, lifter and traverse units to realize automatic cycle control.

3. Thirdly, the pre-designed components save cost and time for customers. At the same time, subsequent maintenance is simple and convenient.

4. Fourthly, strong applicability. It can change the assembly line conveyor system for different products or processes. Therefore, it is especially suitable for industries with fast product replacement, such as the electronics industry.

5. Finally, the system has high accuracy. Various high-precision guidance, positioning, detection components are used on the machine. Thereby, it ensures the high precision of product assembly.

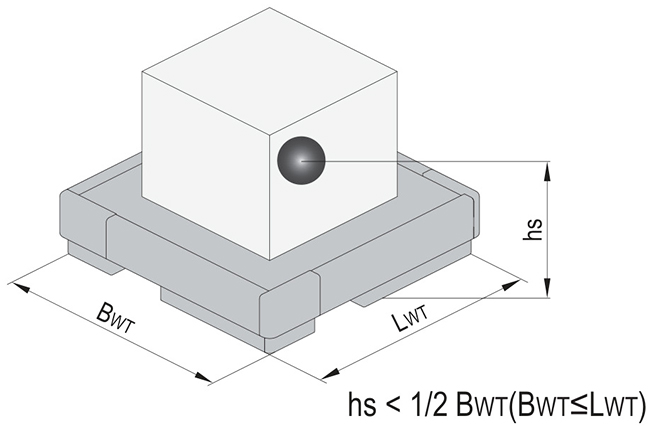

Introduction of Modular Wokpiece Pallet Tooling Board

The pallet acts as the transferring tool to convey the workpiece to each work station.The modular pallet will be stopped by the blocker when it arrives at the work station.

| BWT(mm) | LWT(mm) | Frame Weight-A (KG) | Max Uniform Load (KG) |

|

160 |

160 | 1.51 | 16 |

| 240 | 2.04 | 16 | |

| 320 | 2.58 | 16 | |

|

240 |

240 | 2.67 | 24 |

| 320 | 3.32 | 24 | |

| 400 | 3.89 | 24 | |

| 480 | 4.51 | 24 | |

|

320 |

320 | 3.99 | 32 |

| 400 | 4.69 | 32 | |

| 480 | 5.40 | 32 | |

|

400 |

400 | 5.60 | 40 |

| 480 | 6.39 | 40 | |

| 480 | 480 | 7.28 | 48 |

| 640 | 640 | 9.71 | 64 |

Characteristics & Advantages of Modular Conveyor Workpiece Pallet

1. The workpiece pallet composes of anti-static corner seat and aluminum profile support frame.

2. Because the modular conveyor pallet is with high-precision positioning pin sleeves, the positioning accuracy can reach ±0.1mm. So assembly line belt conveyor can meet high accuracy assembly requirement.

3. The carrying capacity of the pallet is 2kg/cm in the length direction.

4. In order to ensure the life, the pallet load needs to be evenly distributed at the center of the pallet.

5. The standard sensor gasket is used to detect the position of the pallet with the proximity switch.

6. The tooling pallet is made of 5mm, 8mm or 12mm thick steel plate or aluminum plate. The aluminum plate is anodized. The steel plate is treated with black electrophoresis.

Reviews

There are no reviews yet.