Katrangan

Iki minangka oven conveyor roller kanggo pelanggan Prancis. Iki oven conveyor inframerah suhu dhuwur kanggo masak fragmen plastik. Suhu kerja 250 ℃ lan suhu maksimal. yaiku 300 ℃. Pelanggan nyelehake fragmen plastik ing nampan baja, banjur lebokake tray ing conveyor roller kanggo perawatan panas. Amarga suhu dhuwur, kita nggunakake 304 rol stainless steel. Kajaba iku, oven terowongan industri sing terus-terusan iki kalebu telung bagean. Yaiku tegese, conveyor entri, konveyor metu lan tungku trowongan tengah.

Tungku pangatusan nggunakake sirkulasi hawa panas + cara panas IR sing adoh. Suhu kasebut seragam ing oven terowongan industri. Kejaba suhu mundhak kanthi cepet. Oven conveyor inframerah wis aplikasi sudhut ing akeh industri, kayata bagean logam hardware, plastik, nyithak layar, nutupi bubuk, PCB utawa elektronik, lsp. Tungku conveyor bisa uga duwe fungsi pangatusan lan pangobatan. Kajaba iku, oven conveyor uga cocog kanggo industri panganan, kayata pizza, biskuit, roti lan panganan laut. Bisa uga duwe pengaruh nalika garing, dehidrasi lan sterilisasi.

Kepiye cara kerja oven conveyor infrared?

Oven terowongan industri minangka mesin jinis trowongan sing ngeringake produk liwat konduksi panas, konveksi, lan radiasi. Ana sistem conveyor terus-terusan ing trowongan. Bakal ngasilake gerakan relatif antarane produk lan elemen pemanas liwat rantai conveyor, roller or mesh belt. So as to complete the work of uniform baking and conveying.

There are several types of heating elements, such as infrared heating tubes, stainless steel heating tubes and so on. Infrared rays can reach every corner of the furnace. Then the temperature rises evenly, transferring energy to the object. Sanalika, the wind motor drives the blades to generate hot air circulation. Mula, the upper and lower temperatures in the furnace are more uniform. So as to ensure the quality of oven products. Kajaba iku, bahan jampel termal duwe kinerja jampel termal sing apik lan kanthi efektif bisa nyegah ilang panas.

Data Teknis Oven Terowongan Industri

Apa sing digawe oven terowongan? Tungku conveyor utamane kalebu sawetara bagean, kayata conveyor, jampel & sistem pemanas, sistem kontrol lan sistem perlindungan keamanan.

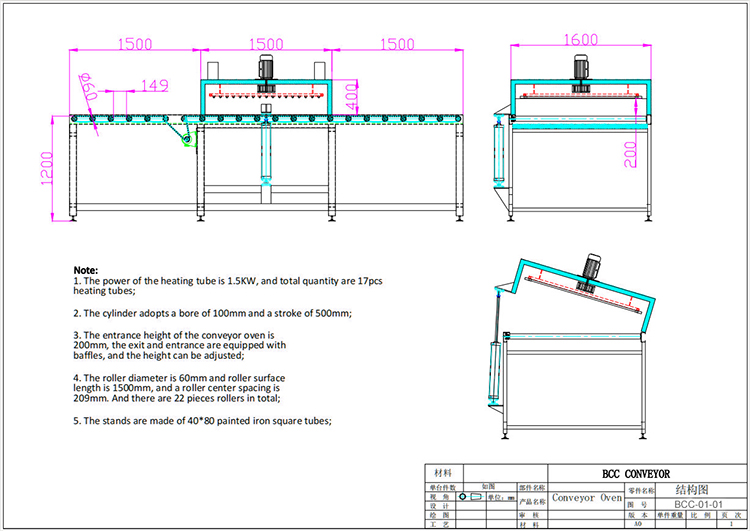

Ing ngisor iki minangka spesifikasi teknis tungku trowongan conveyor roller kanggo pelanggan Prancis.

Dawane total 4,5m lan jembaré sing diwenehake yaiku 1,4m. Kajaba iku, suhu kerja 250 ℃ kanggo 30 menit.

1. Sepisanan, cangkang oven nggunakake 1.5 lembaran galvanis kekandelan.

2. Kapindho, liner njero nggunakake 1.5 kekandelan 304 panel mirror stainless steel. Lan gandheng uga ing saubengé supaya bisa nyegah suhu dhuwur.

3. Kaping telune, gunakake rong lapisan silikat aluminium ketebalan 40mm minangka bahan insulasi.

4. Kaping papat, Tabung pemanas infra merah berkualitas tinggi merek Taiwan: 17pcs, lan saben daya 1,5KW. Dadi kekuwatan oven terowongan industri udakara 25KW.

5. Kaping gangsal, 750W Motor nyopir angin, kanthi bilah kipas kandhang babi 12 inci.

6. Pasang baffle udhara ing sisih kiwa lan tengen. Nalika oven conveyor infrared dadi panas, nutup kanthi manual. Banjur oven trowongan wiwit bisa digunakake. Kajaba iku, ana 2 outlet udara ing sisih ndhuwur.

7. Kaping nem, kontrol kothak listrik:

Merek Chint. Kanthi ngalih udara proteksi bocor, miwiti ngalih, lampu indikator. Kanthi termometer tampilan digital, Kontaktor Chint AC, kothak kontrol independen kanggo tungku pangatusan.

Rentang suhu wiwit suhu ruangan nganti 300 ℃. Kontrol wektu. Fungsi weker. Setel kontrol suhu kanthi otomatis. Lan gunakake termostat RKC.

8. Kajaba iku, ana silinder kanggo ngangkat tutup oven kanggo perawatan.

10. Appearance color: powder spraying, and color is deep-gray as request.

11. The side guide rails of the roller conveyor are bent into a C shape with a 3mm thickness cold rolled plate.

12. The support stands use 40*80 2.0mm thick square steel tube. Kajaba iku, they are with M14 adjusting foot (height-adjustable from 1200 to 1300mm).

13. Salajengipun, kita nggunakake 304 rol stainless steel. Double-row gears. The roller thickness is 2mm. Diameter is 60mm. And roller spacing is 150mm.

14. Pungkasane, roller conveyor uses the AQL brand 750W motor. The speed ratio is 1:60. The speed is 1~7m/min adjustable. Equipped with Delta 750W VFD frequency converter.

Menapa malih, conveyor bisa pindhah ing loro arah.

Cathetan apik: merek kontrol piranti elektronik liyane uga kasedhiya, kayata GAMBAR, Schneider utawa Siemens. Kajaba iku, merek termostat lan motor conveyor uga bisa disesuaikan.

Karakteristik Tungku Tunnel Industri

1. The heating time of infrared conveyor oven is fast. Kajaba iku, the temperature is stable and accurate. Due to the use of hot air circulation and infrared heating, the temperature uniformity is good. So it is conducive to product heat treatment.

2. Using intelligent temperature controller PID automatic calculation. lan, cooperate with SSR solid state relay. Mula, it can control the accuracy of the temperature accurately.

3. Due to the thermal insulation cotton, high temperature resistant sealing strip and entrance & exit barrier plates, the heat insulation effect is good. Sanalika, the outer shell temperature of industrial tunnel oven is low. So there has little effect on the indoor environment temperature.

4. Ing kahanan normal, the upper cover of the infrared conveyor oven is relatively heavy. Mula, we add cylinder or an electric lifting rod onto conveyorfurnace. This facilitates maintenance and replacement of the heating tube.

5. The electrical control is safe and reliable, with dual over-temperature protection functions. At the same time it’s with an emergency button.

Ulasan

Durung ana review.