Katrangan

Conveyor aliran gratis uga yaiku nglumpukake conveyor rantai roller utawa conveyor chain kacepetan pindho. Mirip karo conveyor rantai normal, uga mesin conveyor sing nggunakake rantai minangka bagean traksi lan produk. Nanging uga ana bedane. Prinsip ngirim yaiku nggunakake fungsi nambah kacepetan ranté kacepetan dobel. Mula, palet workpiece sing ndhukung produk bisa mlaku kanthi cepet. Conveyor chain aliran gratis umume digunakake ing jalur produksi perakitan. It can realize the complementarity of each work station.

Apa rantai conveyor aliran bebas?

Beda karo conveyor rantai normal, nggunakake rantai akumulasi. Dadi apa bedane? Kepiye cara kerja rantai conveyor aliran gratis?

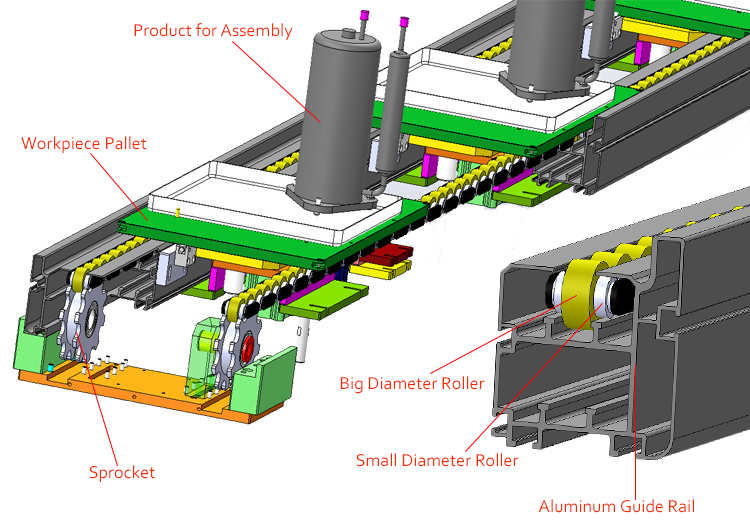

Ndhuwur kabeh, rantai kacepetan pindho nyipta rol diameter gedhe, rol diameter cilik lan tautan rantai gabungan. The small rollers run on the guide rail, and big rollers support the workpiece pallets. Nalika nyeret kabeh rantai kanggo pindhah, iku sejatine rol cilik sing obah ing rel pandhuan. Kosok baline, nalika kabeh rantai gerakane, rol gedhe lan rol cilik pindhah kanthi bebarengan. Kanthi tembung liyane, nalika roller cilik mbukak sak lingkaran, roller gedhe uga mbukak sak lingkaran. Nanging, amarga beda diameteripun, jarak gerakane sing sejatine ing arah horisontal beda. Jarak jarak roller amba luwih gedhe tinimbang roller cilik.

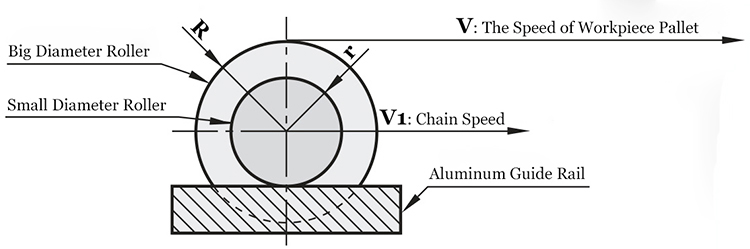

Contone, rantai conveyor aliran gratis mlaku kanthi kecepatan V1. Banjur kecepatan turnover roller cilik yaiku V1. Ing wektu iki, kacepetan turnover roller amba yaiku (R / r)*V1. Mula, kacepetan mlaku (V) palet workpiece yaiku jumlah kacepetan roller gedhe lan kacepetan rantai. Yaiku, V =(R / r)*V1 + V1 =(R / r + 1)*V1. Yen rasio radius roller gedhe menyang roller cilik yaiku 1.5:1, kacepetan palet conveyor yaiku V =(1.5+1)*V1 = 2,5 * V1.

Kacepetan mlaku produk luwih cepet tinimbang rantai akumulasi. Mula, amarga struktur khusus rantai kacepetan dobel, ngasilake efek sing nambah cepet. Mesthi wae, amarga struktur rantai, nambah kacepetan rantai akumulasi winates. Efek nyepetake aliran conveyor gratis yaiku V =(2~ 3)*V1. Spesifikasi umum yaiku 2.5 kaping chain conveyor kacepetan lan 3 kaping chain conveyor kacepetan.

Napa kudu nambah rantai conveyor?

Garis perakitan manual tradisional mbutuhake para pekerja ing kaloro pihak. Contone, there is an air conditioning assembly line. Twist the screws in the first station. Stasiun nomer loro nginstal bagean liyane. Stasiun nomer telu diwenehi label. Efisiensi operasi manual ora mesthi dhuwur banget. To improve production efficiency, kita wiwit nggunakake conveyor chain aliran gratis.

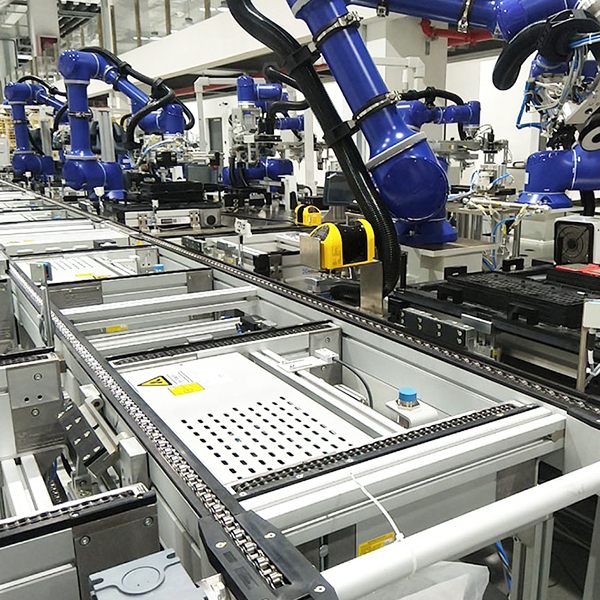

The accumulating roller chain can quickly move the pallet from one process to the next. Ing baris majelis konektor rantai cepet, saben proses dioperasikake dening robot. Kanggo nggampangake operasi robot, nambah mekanisme pamblokiran.

Parameter Teknis Konveyor Rantai Kacepetan Ganda

|

Free flow chain conveyor length |

2000mm~40000mm |

|

Ukuran pallet workpiece |

160~800mm |

|

Dhuwur conveyor Déwan palet |

Custom kaya kabutuhan |

|

Kapasitas beban maksimal (gunggunge) |

200KG / 500KG /2000KG |

|

Kacepetan ngirimake (maksimal mbukak) |

20m / mnt |

|

Media konveyor |

08BS / BS25 Accumulating roller chain |

|

Bahan bingkai |

Special Aluminum profile |

|

Jinis instalasi motor |

Pungkasi drive utawa drive tengah |

The Characteristic of Accumulating Roller Chain Conveyor

1. Kaping kabeh, it uses a special aluminum profile as the guide rail. So it makes the double speed chain conveyor have very good stability and durability during the conveying process. Mula, it’s suitable for continuous mass production of products.

2. Kapindho, it can move the workpiece for long distance. And speed can be fast. Sanalika, it can realize accumulation type conveying to prevent material backlog.

3. Kaping telune, the conveying capacity is large. Kajaba iku, free flow chain conveyor can carry a large load. Loads from 200KG to 2000KG are applicable.

4. It can meet the needs of a variety of production processes, such as glue dispensing, large screws, welding, lsp.

5. Kajaba iku, accumulating roller chain conveyor can achieve a variety of test requirements, such as CCD vision, photoelectric detection, resistance detection, withstand voltage detection, product function detection, lsp.

6. Free flow conveyor can be applicable to various types of similar products. Menapa malih, if customers need to increase product types, they can quickly upgrade and transform.

7. The double-speed chain assembly conveyor is flexible. Contone, when we need to improve production efficiency, we can increase the number of pallets and work stations. vice versa. Kosok baline, it can also design complex product flow. Contone, we can add horizontal traversing and turning devices to realize a horizontal circular assembly line. Or to achieve a more complex shape of the assembly line.

8. Pungkasane, it can realize intelligent manufacturing functions. The running data, inspection data and production data of the entire production line can be saved and summarized. So it’s convenient to read online or online.

How to choose free flow chain conveyor?

When you need to customize the free flow chain assembly conveyor, please confirm the below details:

1. Sepisanan, it needs to inform the size and weight of the product. Because this will affect the selection of tooling board and motor power.

2. Kapindho, clarify the shape and layout of the accumulating roller chain conveyor. Is it a straight line, a horizontal loop or a vertical loop?

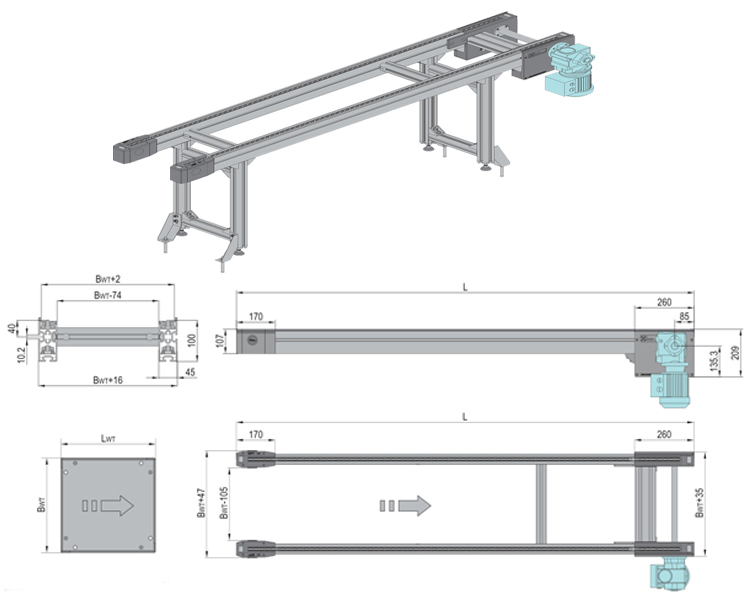

3. Kaping telune, determine the size of the double-speed chain conveyor. The longest can be 30-40 meter. The width is generally 250~900mm (bisa disesuaikan). Kajaba iku, the height is generally 500~1200mm.

4. Kaping papat, confirm the operating speed of the free flow chain conveyor. Umume, the maximum speed is 20m/min.

5. Kaping gangsal, determine the type of double-speed chain. The speed is divided into 2.5 times and 3 kaping. The large rollers can be stainless steel and engineering plastics.

6. Material selection: there are a variety of materials for workpiece pallets to choose from, such as aluminum, steel, engineering plastic, wood, lsp. The frame materials are generally aluminum profiles and painted steel.

7. Kajaba iku, it is best to inform your process flow. Sanalika, inform whether there are additional functions onto free flow conveyor, such as product testing.

8. Pungkasane, confirm the power supply: single-phase 220V / three-phase 380V 50Hz or others.

How to replace free flow conveyor chain?

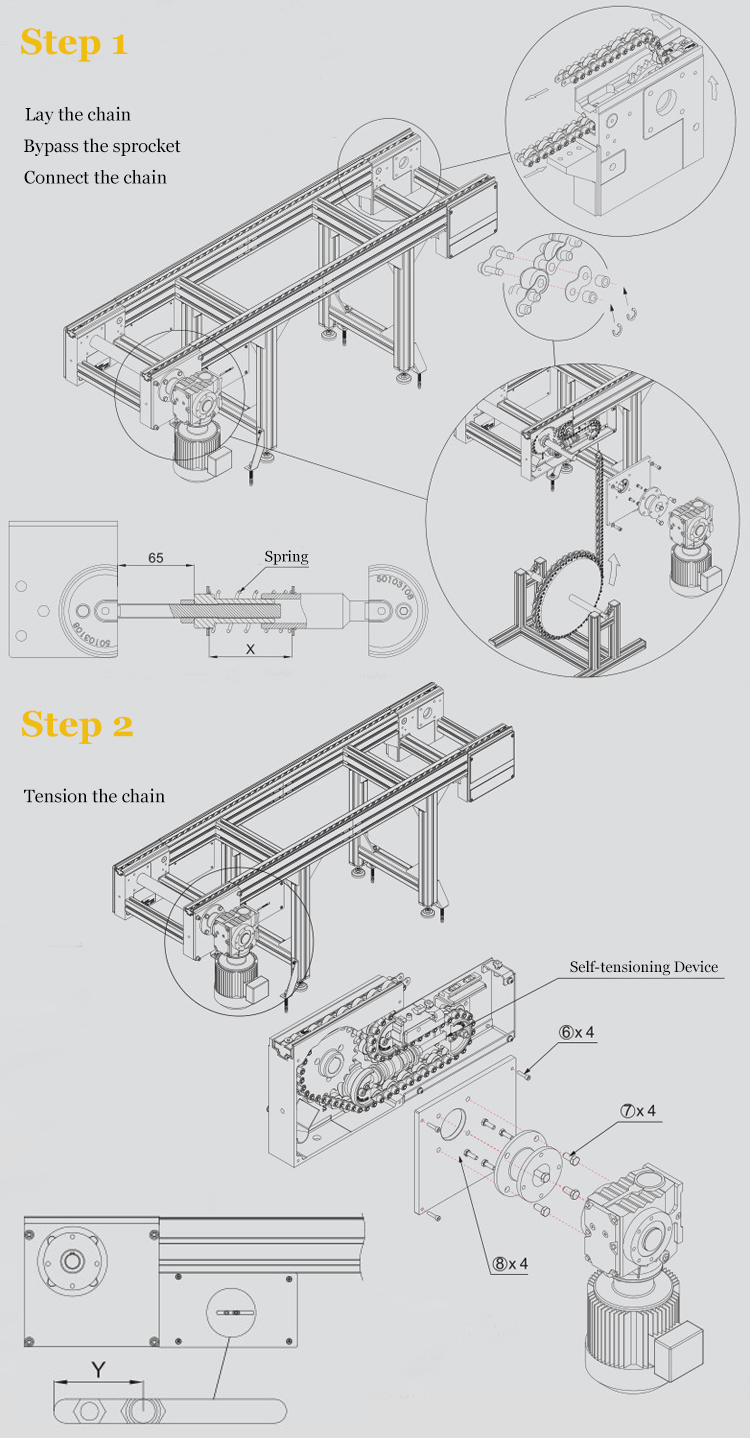

Nyatane, the installation of accumulating rolller chain conveyor is other chain conveyors. When you need to replace the free flow conveyor chain, remove the old chain firstly. Banjur, place the chain on the chain shaft in order to avoid chain damage. And guide the chain trough the lower part of the drive unit. Sanalika sawise, bypass driven sprocket, the drive end and the drive sprocket in turn. Finally connect the double speed conveyor chain.

Similar to belt conveyor, free flow conveyor also needs to tighten the chain. Otherwise it will influence the load-bearing capacity of the conveyor assembly line.

Cathetan apik: this free flow chain conveyor has self-tensioning device. It needs often observe the length of Y. Kajaba iku, it must ensure that 35≤Y≤55.

How to maintain accumulating roller chain conveyor?

Before starting the free flow chain conveyor daily, we should check whether there are fragments in the chain. Yen ora, it will damage the chain. Kajaba iku, clean the assembly conveyor line each week. And often check if the double speed conveyor chain is loose. Sanalika, check whether the chain needs lubrication.

Chain lubrication

Before starting the free flow conveyor for the first time, you must lubricate chain. How to lubricate the chain? Drage the whole chain. Lubricate the chain with an amount of about 2~3ml/m. Recommend 15W40 Shell oil.

Kajaba iku, as long as the equipment is down for more than 6 months, you need re-lubricate it. Before lubricating, remove excess grease, oil stains or other impurities on the accumulating roller chain. Sanalika, check whether the chain is worn or stretched. Lubrication method and oil volume are the same as above.

During normal use of the assembly conveyor, it needs re-lubricate the chain every 1000 jam. Lubricate a small amount each time-about 2ml/m. Kajaba iku, if the operating environment has high humidity, we should shorten the interval time between each lubrication according to the actual situation.

Mesthi wae, we can customize the self-lubrication system. It can optimally and uniformly lubricate the free flow conveyor chain during equipment operation.

When using the free flow conveyor, yen ana kahanan darurat, press the red emergency stop switch immediately. Then turn off the power and start the solution.

Ulasan

Durung ana review.