Paglalarawan

Libreng daloy ng conveyor ay katulad din naipon ng roller chain conveyor o conveyor ng dobleng bilis. Katulad ng normal na conveyor ng kadena, isa rin itong conveyor machine na gumagamit ng chain bilang bahagi ng traksyon at produkto. Ngunit mayroon ding pagkakaiba. Ang prinsipyo ng paghahatid ay upang gamitin ang bilis ng pagtaas ng pag-andar ng kadena ng dobleng bilis. Samakatuwid, ang workpiece pallet na sumusuporta sa mga produkto ay maaaring tumakbo nang mabilis. Libreng daloy ng conveyor ng kadena pangunahing ginagamit sa mga linya ng produksyon ng pagpupulong. It can realize the complementarity of each work station.

Ano ang chain ng conveyor ng libreng daloy?

Naiiba mula sa normal na conveyor ng kadena, gumagamit ito ng naipon na chain ng roller. Kaya ano ang pagkakaiba sa pagitan nila? Paano gumagana ang libreng daloy ng conveyor chain?

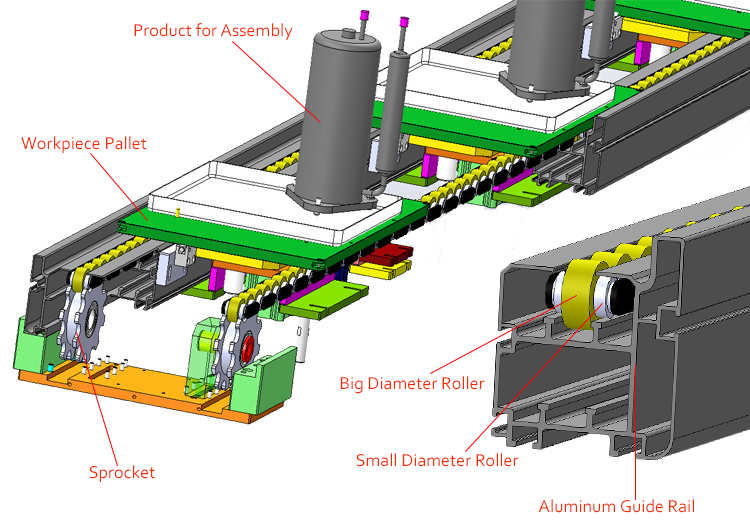

Higit sa lahat, ang dobleng bilis na kadena ay bumubuo ng mga malalaking diameter na rol, maliit na diameter na mga roller at magkasanib na mga link ng chain. The small rollers run on the guide rail, and big rollers support the workpiece pallets. Kapag hinihila namin ang buong kadena upang ilipat, ito ay talagang maliit na mga roller na gumagalaw sa gabay na riles. Sa kabilang kamay, kapag gumalaw ang buong kadena, ang malalaking roller at ang maliliit na roller ay magkasabay na gumagalaw. Sa ibang salita, kapag ang maliit na roller ay tumatakbo para sa isang bilog, ang malaking roller ay tumatakbo din para sa isang bilog. Gayunpaman, dahil sa pagkakaiba ng diameter, ang kanilang tunay na distansya ng paggalaw sa pahalang na direksyon ay magkakaiba. Ang distansya ng pagtakbo ng malaking roller ay mas malaki kaysa sa maliit na roller.

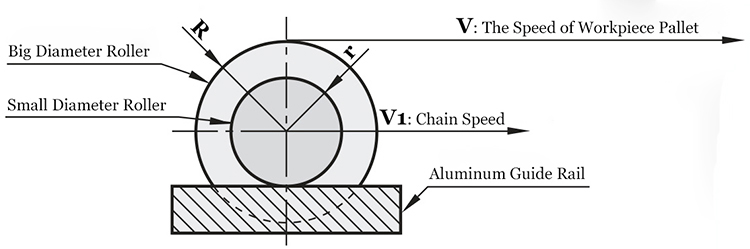

Halimbawa, ang free flow conveyor chain ay tumatakbo sa bilis ng V1. Pagkatapos ang bilis ng paglilipat ng tungkulin ng maliit na roller ay V1. Sa oras na ito, ang bilis ng turnover ng malaking roller ay (R / r)*V1. Samakatuwid, ang bilis ng takbo (V) of the workpiece pallet is the sum of the large roller speed and the chain speed. Yan ay, V=(R / r)*V1+V1=(R/r+1)*V1. If the ratio of the radius of the big roller to the small roller is 1.5:1, the speed of the conveyor pallet is V=(1.5+1)*V1=2.5*V1.

The running speed of the product is faster than that of the accumulating roller chain. Samakatuwid, due to the special structure of the double-speed chain, it produces the speed-increasing effect. Syempre, due to the chain structure, ang bilis ng pagtaas ng naipon na roller chain ay limitado. Ang karaniwang bilis ng epekto ng libreng daloy ng conveyor ay V =(2~ 3)*V1. Karaniwang mga pagtutukoy ay 2.5 beses na bilis ng conveyor chain at 3 beses na bilis ng conveyor chain.

Bakit kailangan makaipon ng roller chain conveyor?

Ang linya ng tradisyunal na manu-manong pagpupulong ay nangangailangan ng mga manggagawa sa magkabilang panig. Halimbawa, may linya ng pagpupulong ng aircon. I-twist ang mga tornilyo sa unang istasyon. Ang ikalawang istasyon ay nag-i-install ng iba pang mga bahagi. Ang pangatlong istasyon ay may label. Ang kahusayan ng manu-manong operasyon ay hindi palaging napakataas. To improve production efficiency, we began to use free flow chain conveyor.

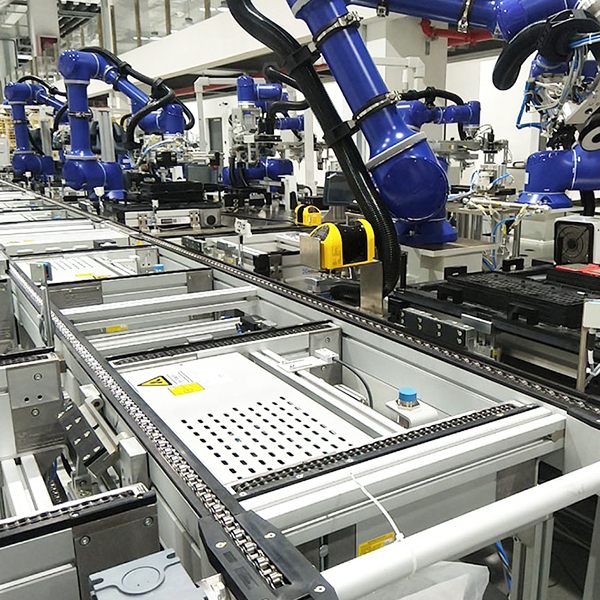

The accumulating roller chain can quickly move the pallet from one process to the next. In the double-speed chain conveyor assembly line, each process is operated by robots. Upang mapadali ang pagpapatakbo ng robot, nagdadagdag ito ng mga mekanismo ng pagharang.

Mga Teknikal na Parameter ng Double Speed Chain Conveyor

|

Ang haba ng daloy ng conveyor chain |

2000mm~40000mm |

|

Laki ng workpiece na papag |

160~ 800mm |

|

Taas ng conveyor ng pagpupulong ng palyet |

Pasadya kung kinakailangan |

|

Max kapasidad sa pag-load (kabuuan) |

200KG / 500KG / 2000KG |

|

Ang bilis ng paghahatid (todong kargahe) |

20m / min |

|

Medium ng conveyor |

08BS / BS25 Naipon ng chain ng roller |

|

Materyal ng frame |

Espesyal na profile ng Aluminium |

|

Uri ng pag-install ng motor |

Tapusin ang drive o center drive |

The Characteristic of Accumulating Roller Chain Conveyor

1. Una sa lahat, it uses a special aluminum profile as the guide rail. So it makes the double speed chain conveyor have very good stability and durability during the conveying process. Samakatuwid, it’s suitable for continuous mass production of products.

2. Pangalawa, it can move the workpiece for long distance. And speed can be fast. At the same time, it can realize accumulation type conveying to prevent material backlog.

3. Pangatlo, the conveying capacity is large. Bukod sa, free flow chain conveyor can carry a large load. Loads from 200KG to 2000KG are applicable.

4. It can meet the needs of a variety of production processes, such as glue dispensing, large screws, welding, atbp.

5. At saka, accumulating roller chain conveyor can achieve a variety of test requirements, such as CCD vision, photoelectric detection, resistance detection, withstand voltage detection, product function detection, atbp.

6. Free flow conveyor can be applicable to various types of similar products. Bukod dito, if customers need to increase product types, they can quickly upgrade and transform.

7. The double-speed chain assembly conveyor is flexible. Halimbawa, when we need to improve production efficiency, we can increase the number of pallets and work stations. vice versa. Sa kabilang kamay, it can also design complex product flow. Halimbawa, we can add horizontal traversing and turning devices to realize a horizontal circular assembly line. Or to achieve a more complex shape of the assembly line.

8. Sa wakas, it can realize intelligent manufacturing functions. The running data, inspection data and production data of the entire production line can be saved and summarized. So it’s convenient to read online or online.

How to choose free flow chain conveyor?

When you need to customize the free flow chain assembly conveyor, please confirm the below details:

1. Una, it needs to inform the size and weight of the product. Because this will affect the selection of tooling board and motor power.

2. Pangalawa, clarify the shape and layout of the accumulating roller chain conveyor. Is it a straight line, a horizontal loop or a vertical loop?

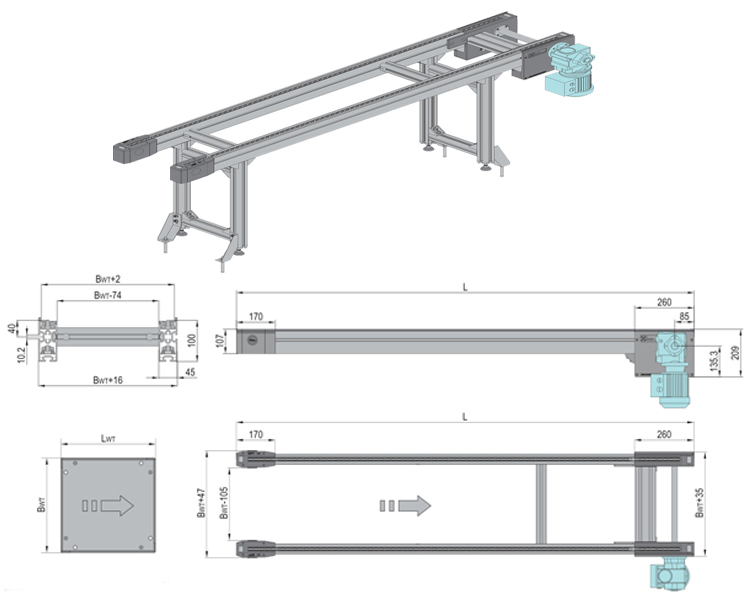

3. Pangatlo, determine the size of the double-speed chain conveyor. The longest can be 30-40 metro. The width is generally 250~900mm (napapasadyang). Bilang karagdagan, the height is generally 500~1200mm.

4. Pang-apat, confirm the operating speed of the free flow chain conveyor. Sa pangkalahatan, the maximum speed is 20m/min.

5. Panglima, determine the type of double-speed chain. The speed is divided into 2.5 times and 3 mga oras. The large rollers can be stainless steel and engineering plastics.

6. Material selection: there are a variety of materials for workpiece pallets to choose from, such as aluminum, bakal, engineering plastic, kahoy, atbp. The frame materials are generally aluminum profiles and painted steel.

7. At saka, it is best to inform your process flow. At the same time, inform whether there are additional functions onto free flow conveyor, such as product testing.

8. Sa wakas, confirm the power supply: single-phase 220V / three-phase 380V 50Hz or others.

How to replace free flow conveyor chain?

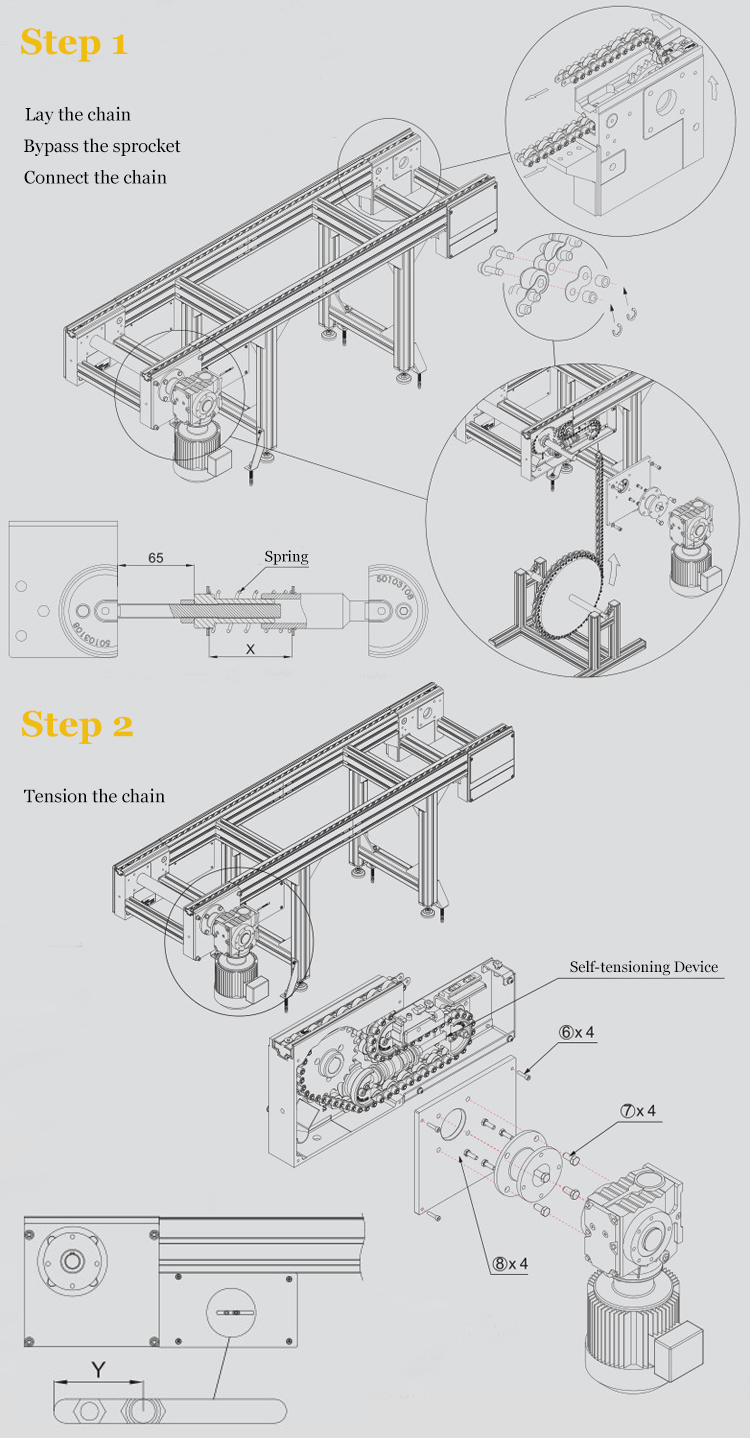

Sa totoo lang, the installation of accumulating rolller chain conveyor is other chain conveyors. When you need to replace the free flow conveyor chain, remove the old chain firstly. Tapos, place the chain on the chain shaft in order to avoid chain damage. And guide the chain trough the lower part of the drive unit. Kaagad pagkatapos, bypass driven sprocket, the drive end and the drive sprocket in turn. Finally connect the double speed conveyor chain.

Similar to belt conveyor, free flow conveyor also needs to tighten the chain. Otherwise it will influence the load-bearing capacity of the conveyor assembly line.

Kind note: this free flow chain conveyor has self-tensioning device. It needs often observe the length of Y. Bukod sa, it must ensure that 35≤Y≤55.

How to maintain accumulating roller chain conveyor?

Before starting the free flow chain conveyor daily, we should check whether there are fragments in the chain. Kung hindi man, it will damage the chain. At saka, clean the assembly conveyor line each week. And often check if the double speed conveyor chain is loose. At the same time, check whether the chain needs lubrication.

Chain lubrication

Before starting the free flow conveyor for the first time, you must lubricate chain. How to lubricate the chain? Drage the whole chain. Lubricate the chain with an amount of about 2~3ml/m. Recommend 15W40 Shell oil.

At saka, as long as the equipment is down for more than 6 months, you need re-lubricate it. Before lubricating, remove excess grease, oil stains or other impurities on the accumulating roller chain. At the same time, check whether the chain is worn or stretched. Lubrication method and oil volume are the same as above.

During normal use of the assembly conveyor, it needs re-lubricate the chain every 1000 oras. Lubricate a small amount each time-about 2ml/m. At saka, if the operating environment has high humidity, we should shorten the interval time between each lubrication according to the actual situation.

Syempre, we can customize the self-lubrication system. It can optimally and uniformly lubricate the free flow conveyor chain during equipment operation.

When using the free flow conveyor, if there is an emergency, press the red emergency stop switch immediately. Then turn off the power and start the solution.

Mga pagsusuri

Wala pang mga review.