Kirjeldus

See on komme tunneli ahi kuivatusahi kliendile. Nad kasutavad seda ravimipudelite kuivatamiseks. Nii et selle kuumutamistemperatuur pole kõrge (85℃). See on omamoodi pidev vöökuivati. (Muidugi, tavaliselt kohandame ka kõrge temperatuuriga konveierkuivatit). Selle võrgusilma kogupikkus rihmahi on 8.6 meetrit. Sellel on 6 küttetsoonid. Tunnelkuivati nurgas, see on 90 ° kõver PVC lintkonveier. Muu 2 konveiermasinad kasutavad teflonvõrku.

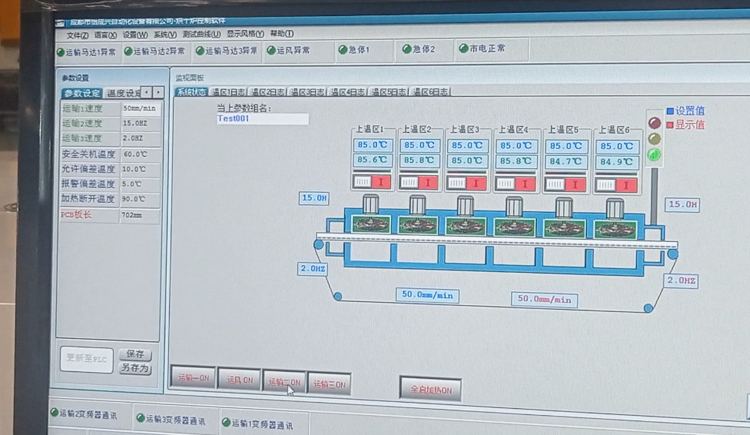

See on tööstuslik infrapunakonveieri ahi. Igal kuivatustsoonil on 6 tk IR -küttetorud. Lisaks, see pidev tunneli ahi on juhtimissüsteem. Klient saab võrgusilma ahju arvutiga hõlpsalt juhtida ja juhtida.

Mis on tunneliahju ahi?

See on omamoodi pidev vöökuivati. Erineb kuivatusahjust, sellel on toodete transportimiseks konveier. Seega ei pea inimesed sageli tooteid liigutama. Kuna konveierkuivati näeb välja nagu tunnel, seda nimetatakse sageli tunneliahjuks. Võrgusilma kuivatit saate kasutada koos teiste tootmisliinidega. Nii et tunneliahjus on palju omadusi, näiteks kõrge tootmisefektiivsus, tööjõu kokkuhoid, ja stabiilne küpsetuskvaliteet.

See tunneliahi koosneb teflonist lintkonveierist, kumer PVC lintkonveier, kütteahi ja temperatuuri juhtimissüsteem. Esiteks, tooted sisenevad rihmaahju sissepääsu tsoonist. Seejärel liigutab konveierlint toodet määratud kiirusel. Konveieri ahjus olev kütteelement kuivatab toote. Kui kuivatamine on lõppenud, tooted väljuvad väljumistsoonist.

Kuidas töötab pidev tunneliga ahi?

Hetkel, kuuma õhu ringlus on konveierkuivati tavaline kuumutusmeetod. Soojendamiseks kasutatakse konvektsioonijuhtimise põhimõtet. Ja kütteelement võtab kasutusele infrapuna kütteseadmete torud. Infrapuna küttetoru asub konveieri ahju ülemisel kaanel. Lisaks, rihmahjus on ventilaator. Infrapunatundlikud valgusallikad võivad särada lint ahju igas nurgas. Samal ajal, sisemine sooja õhu ringlussüsteem soodustab ühtlasemat temperatuuri tunneli ahjus. Lisaks, alumiinium silikaatkiud täidetakse sisemise voodri ja väliskesta vahel isolatsioonikihina. Nii et isolatsioon on hea.

Pideva lintkuivati iga töötsooni juhitakse sõltumatult. Termostaadi tõttu, see saab reaalajas juhtida konveieri tunneli ahju temperatuuri. Ja meie konveierkuivati temperatuuritaluvus võib ulatuda ± 3 ℃.

Pideva lintkuivati tehnilised andmed

Below are the technical specifications of 6 heating zones tunnel furnace as above video. Muidugi, we can customize the tunnel conveyor oven as customer’s requirements.

-

1. Mesh belt conveyor

- The conveyor consists of 2 sets of teflon mesh belt conveyor and 1 set of 90° curve conveyor. The belt width is 800mm. Under the mesh belt is a 1.5mm galvanized carrying plate with holes. Each conveyor uses 750W 3-phase motor with Delta brand VFD frequency converter. Ja pideva lintkuivati edastuskiirus on reguleeritav 0 ~ 5 m/min.

Konveierilindi ahju alused on 40*40 mm värvitud süsinikterasest torud. Ja seal on reguleeritava kõrgusega jalad. The mesh belt conveyor uses φ50mm driving and driven rollers. And curved conveyor uses cone rollers.

2. Heating oven

There are 6pcs of heating zones in this tunnel furnace. The outermost are outer convers for each oven. The material is painted carbon steel plate. The bracket can support the shell. Below the outer shell is the inner shell. The material is stainless steel plate. Lisaks, there are electric push rods to lift the inner shells. So it is convenient for customers to repair the conveyor belt furnace. And the height of entrance area is 100mm.

Each conveyor oven uses 6pcs of infrared heater tubes. The IR heating tubes are installed on the stainless steel mirror plate. The wind motor is Taiwan brand 750W motor. And the impeller fan is connected to the wind motor. Centrifugal fan impleller can effectively promote the circulation of hot air in the furnace. Lisaks, there are high temperature resistant sealing strips. So it can avoid heat escaping. The surface of tunnel furnace oven adopts white color powder-coating. And there are exhaust vents on continuous belt dryer.

3. Kontrollsüsteem

This continuous belt dryer has intelligent control system. So you can directly control the tunnel belt furnace on the computer. Näiteks, it can adjust the conveyor speed and drying temperature. It uses the RKC brand thermostat. Automatic constant temperature control. Other control circuit appliances adopt Chint Electric. Lisaks, there are emergency control button, over-temperature power-off alarm, leakage protection, motor overload protection and other functions.

Operation instruction of continuous belt dryer

In order to protect the health and safety of end users, help users choose safe methods to operate the conveyor belt furnace. The use method and precautions of the tunnel furnace are as follows.

1. Installation and power distribution requirements

Adjust the feet to ensure that the conveyor dryer is level and stable.

Input power: three-phase five-system, 380V, 50HZ/60HZ;

Maximum power: 54KW;

Power cord: three-phase five-wire, the power cord is not less than 6m㎡;

Ensure that continuous belt dryer is well grounded to prevent personal safety due to leakage.

2. Operate the continuous tunnel furnace

(1) Start the conveyor dryer

Esiteks, open the control electric box and the air switch.

Teiseks, press the power button. Then directly operate the system on the computer. Turn on the conveyor and the conveyor belt starts to run. Edasi, start the wind motor. So centrifugal impleller fan starts to work.

Kolmandaks, set the working temperature of conveyor belt furnace. Enter the drying temperature directly on the computer. At the computer also shows the actual temperature in the tunnel oven.

Lisaks, it can also set the belt conveyor speed on the computer. So customer can control the drying time.

(2) Shut down the continuous belt dryer

First, check whether all the products in the tunnel dryer out of the equipment.

Teiseks, turn off the temperature control switches, from “peal” juurde “off”

Kolmandaks, run empty for 10-15 minutit

Siis, turn off the conveyor, wind motor and power supply in turn.

Lõpuks, turn off the air switch and the main power supply.

Lisaks, if there is an emergency, you can press the emergency button.

3. Conveyor belt furnace maintenance

Press the buttons to lift the outer covers of the tunnel furnace. So you can fix the tunnel oven and exchange the heating lamps.

After a period of normal operation, the conveyor dryer needs frequent maintenance.

Customer can adjust the conveyor belt by the tensioning device. It can prevent deviation of oven conveyor belt.

Pay attention to keep the electric box clean. To avoid accumulation of dust, electrical short-circuit phenomenon occurs.

Lubricate the conveyor chain every week.

Lisaks, always check the fixing bolts of the belt furnace and conveyor to prevent loosening.

KKK

Q1: Kui kasutame süstimisosade kuivatamiseks konveierilindi ahju, kas see muudab plastiku suurust?

A1: Kui tunneli ahju kuivatustemperatuur on kõrge, see muudab toote suurust. Kuid plastist osade süstimiseks, küttetemperatuur ei ole tavaliselt kõrge, nii et see ei muuda plastiku suurust.

Q2: What’s the appplication of the continuous belt dryer?

A2: This industrial tunnel oven is special for drying pharmaceutical bottles. Muidugi, this conveyor dryer can be also suitable for screen printing, cosmetic bottles, injection plastic parts, PCB, elektroonilised tooted, jne.

Q3: What is the drying time in continuous tunnel furnace?

A3: Our customer uses this conveyor belt furnace to dry pharmaceutical bottles for 16 minutes each time. Muidugi, you can adjust the conveying speed to change the drying time.

Q4: What is the difference between tray dryer and tunnel dryer?

A4: Tray dryer is suitable for small batch drying. But it’s not for big batch baking. Sellel ajal, it needs tunnel conveyor dryer.

Arvustused

Ülevaateid pole veel.