Описание

Това е ролкова конвейерна фурна за нашия клиент във Франция. Това е високотемпературна инфрачервена конвейерна фурна за готвене на пластмасови фрагменти. Работната температура е 250 ℃ и максимална температура. е 300 ℃. Клиентът поставя пластмасовите фрагменти в стоманената тава, и след това поставете тавата върху ролковия конвейер за топлинна обработка. Заради високата температура, ние използваме 304 ролки от неръждаема стомана. В допълнение, тази непрекъсната индустриална тунелна фурна включва три части. Това ще рече, входният конвейер, изходен конвейер и средна тунелна пещ.

Пещта за сушене приема циркулация на горещ въздух + far IR heating method. Температурата е равномерна в индустриалната тунелна фурна. Освен това температурата се повишава бързо. Infrared conveyor oven has wide application in many industries, such as hardware metal parts, пластмасов, ситопечат, powder coating, PCB or electronics, и т.н.. The conveyor furnace can play the role of drying and curing. В допълнение, conveyor oven can also suitable for food industry, such as pizza, бисквити, bread and seafood. It can play a role in drying, dehydrating and sterilizing.

How does infrared conveyor oven work?

The industrial tunnel oven is a tunnel type machine that drying products through heat conduction, convection, and radiation. There is a continuous conveyor system in the tunnel. It will generate the relative movement between the product and the heating element through the conveyor chain, roller or mesh belt. So as to complete the work of uniform baking and conveying.

There are several types of heating elements, such as infrared heating tubes, тръби за отопление от неръждаема стомана и така нататък. Инфрачервените лъчи могат да достигнат до всеки ъгъл на пещта. Тогава температурата се повишава равномерно, прехвърляне на енергия към обекта. По същото време, вятърният двигател задвижва лопатките, за да генерира циркулация на горещ въздух. Следователно, горната и долната температура в пещта са по-еднакви. За да се гарантира качеството на продуктите на фурната. В допълнение, топлоизолационният материал има добри топлоизолационни характеристики и може ефективно да предотврати загубата на топлина.

Технически данни за индустриална тунелна фурна

От какво е направена тунелна фурна? The conveyor furnace mainly includes several parts, such as conveyor, insulation & heating system, control system and safety protection system.

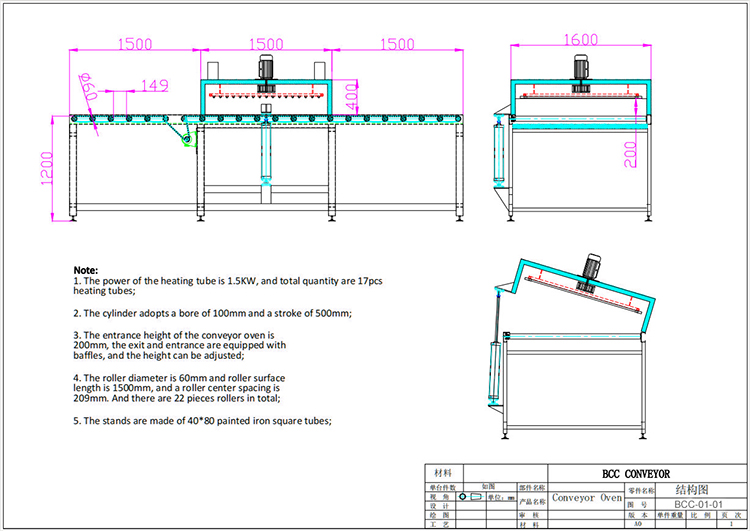

The following are the technical specifications of the roller conveyor tunnel furnace for our French customer.

Total length is 4.5m and conveying surface width is 1.4m. Освен това, the working temperature is 250℃ for 30 минути.

1. Първо, the oven shell uses 1.5 thickness galvanized sheet.

2. Второ, the inner liner uses 1.5 thickness 304 stainless steel mirror panels. And weld well all around in order to prevent high temperature cracking.

3. Трето, use two layers of 40mm thickness aluminum silicate as insulation material.

4. Четвърто, Taiwan brand high-quality infrared heating tube: 17бр, and each power is 1.5KW. So the power of industrial tunnel oven is about 25KW.

5. Пето, 750W Wind-driving motor, with 12-inch pig-cage fan blades.

6. Install the air baffles on the left and right sides. When infrared conveyor oven heats up, close them manually. Then the tunnel oven starts to work. Освен това, има 2 air outlets on the top.

7. Шесто, control electric box:

Chint brand. With leakage protection air switch, start switch, indicator light. With digital display thermometer, Chint AC contactor, independent control box for drying furnace.

The temperature range is from room temperature to 300℃. Timing control. Alarm function. Set automatic temperature control. And use the RKC thermostat.

8. В допълнение, there is cylinders to lift the oven cover for maintenance.

10. Appearance color: powder spraying, and color is deep-gray as request.

11. The side guide rails of the roller conveyor are bent into a C shape with a 3mm thickness cold rolled plate.

12. The support stands use 40*80 2.0mm thick square steel tube. Освен това, they are with M14 adjusting foot (height-adjustable from 1200 to 1300mm).

13. освен това, ние използваме 304 ролки от неръждаема стомана. Double-row gears. The roller thickness is 2mm. Diameter is 60mm. And roller spacing is 150mm.

14. Накрая, roller conveyor uses the AQL brand 750W motor. The speed ratio is 1:60. The speed is 1~7m/min adjustable. Equipped with Delta 750W VFD frequency converter.

освен това, the conveyor can move in both directions.

Любезна бележка: other brands of electronic control devices are also available, such as ABB, Schneider or Siemens. Освен това, the brand of thermostat and conveyor motor can be also customizable.

Characteristics of Industrial Tunnel Furnace

1. The heating time of infrared conveyor oven is fast. Освен това, the temperature is stable and accurate. Due to the use of hot air circulation and infrared heating, the temperature uniformity is good. So it is conducive to product heat treatment.

2. Using intelligent temperature controller PID automatic calculation. И, cooperate with SSR solid state relay. Следователно, it can control the accuracy of the temperature accurately.

3. Due to the thermal insulation cotton, high temperature resistant sealing strip and entrance & exit barrier plates, the heat insulation effect is good. По същото време, the outer shell temperature of industrial tunnel oven is low. So there has little effect on the indoor environment temperature.

4. При нормални обстоятелства, the upper cover of the infrared conveyor oven is relatively heavy. Следователно, we add cylinder or an electric lifting rod onto conveyorfurnace. This facilitates maintenance and replacement of the heating tube.

5. The electrical control is safe and reliable, with dual over-temperature protection functions. At the same time it’s with an emergency button.

Отзиви

Все още няма отзиви.