Description

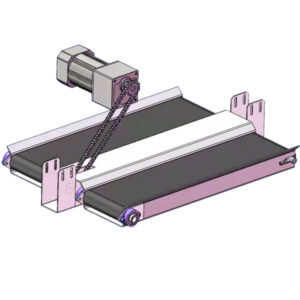

Small conveyor belt system is mainly suitable for the materials handling with small load. Its working principle is that the geared motor drives the roller to drive the belt to convey. And this is a center drive small conveyor system. That is to say, the small conveyor motor, transmission mechanism, and the tensioning mechanism is in the middle of the mini conveyor. Moreover, our small conveyor belt price is cheap. We usually use the small belt conveyor for conveying light duty and small goods.

Miniature conveyor belt has several advatanges. For example, it conveys smoothly and has low noise. Besides it’s easy to install. Because the conveyor frame is aluminum profile and connected by screws, it is easy to disassemble and assemble. Low maintenance costs. Small conveyor belt system is an indispensable equipment for automated production. It can be applicable for material transfer and turnover between various processes. Small conveyor system is not only suitable for electronics, plastics, food, medical, precision parts and other industries, but also can be used in the stamping parts industry.

Technical Specification

Conveyor type: center drive mini belt conveyor;

Frame material: extruded aluminum profile, aluminum panel, SS304 plate, painted steel;

Miniature conveyor belt material: PVC, PU, rubber, modular belt;

Belt color available: green, white, blue, black;

Small conveyor belt price: cheap price;

The speed of small conveyor belt system: custom & speed-adjustable;

The load capacity of conveyor: several kilograms (custom);

Motor: default geared motor + speed controller (of course, other types of motors are also available);

Other accessories available: side bars, stands, sensors, etc.;

Characteristics of Small Conveyor Belt System

1. Firstly, it can customize the belt with anti-running ribs. This can effectively prevent mini belt from running sideways.

2. Secondly, you can specifiy the belt width of small conveyor belt system in units of 10mm. Moreover, it can choose the width and length of the belt according to requirements.

3. Thirdly, the small conveyor motor is located in the middle of the conveyor. The transmission mechanism has a protective cover. Besides, the protective cover can act as bracket.

4. Then the conveyor frame is made of aluminum profiles. Therefore, the overall weight is light. At the same time, we can install the screws in the aluminum profile groove in advance. So this makes it easy for customers to install other components, such as sensors, cylinders, etc.

5. A variety of motors are available. One year warranty, safe and reliable.

6. In addition, it can adjust the running speed of the belt according to the actual production needs.

7. Finally, the small conveyor system can not only convey in the horizontal plane, but also realize the inclined conveying.

How to choose the small belt conveyor system

1. Firstly, it needs to know the conveyor application. If for food use, you need the small food conveyor (food-grade PU or PE belts). At this time, the frame of the small conveyor belt system must be use stainless steel material. In addition, if used in electronic products, we can provide anti-static belts.

2. Secondly, inform the dimensions of the conveyor (length, width and height). At the same time, it needs to know the product weight. So we can know the power of the motor. Therefore, we can provide the best small conveyor belt price.

3. By default, the small conveyor system is without brackets. At the same time, it is equipped with a governor. So you can adjust the speed of the conveyor. The motor is mainland China brand. Of course, it can choose other brands motors are available. In addition, the default is without power supply, cables and switches.

4. Finally, if you need to add some other accessories or functions to the conveyor, please inform to us. For example, we can add the aviation plug. Thus, it can realize the plug-and-unplug function. So it’s very easily used in your automation equipment. Alternatively, it can also add sensors. Then it’s convenient for you to achieve a variety of automatic control.

Precautions for use

1. Ribbed small belt conveyor cannot completely prevent deviation. Therefore, it is necessary to observe the running status of the belt in daily use. If there is belt deviationk, it needs to adjust it in time. For example, when the belt runs to the left, you need to adjust the tension adjustment screw on the left. Until the belt runs normally, then put it into normal use.

2. Do not disassemble the small conveyor system at will. So as not to cause poor performance. At the same time, the running direction of the small belt conveyor is fixed. If change conveying direction, it may not work normally.

3. Carefully check all parts of the mini belt conveyor before starting up. Pay attention to whether there are people and other sundries on the belt. It can only start running when there is no problem after inspection.

4. After starting, run with no load firstly. After confirming that conveyor is normal, then work with load. At the same time, the operator must frequently patrol along the line. Find problems and eliminate them in time.

5. During operation, if there are abnormal phenomena such as belt slippage or random jumping, it should make adjustments in time. When the belt is slipping, it is strictly forbidden to stuff things between the roller and the belt. If the belt tightness is inappropriate, adjust the tensioning device in time.

6. Be sure to add material to the small conveyor belt system evenly. Prevent overfeeding. Otherwise, the belt will be crushed, thereby affecting the safe operation of the machine. In short, the conveyor cannot be overloaded.

Reviews

There are no reviews yet.